3D Printed Climbing Holds - Strength Tested

|

|

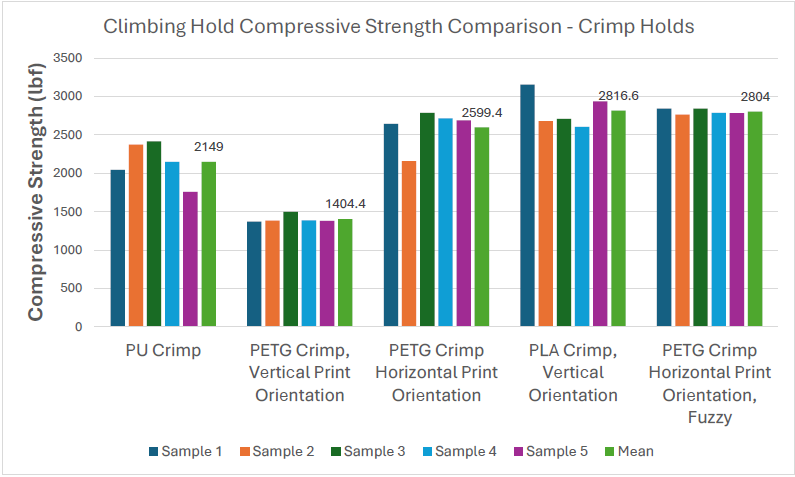

As part of an independent study for my graduate school education in mechanical engineering, I 3D printed indoor climbing holds and tested their strength compared to traditional polyurethane (PU) resin holds. The results of my study suggest that 3D printed climbing holds can be as strong or stronger than traditional climbing holds. For a crimp hold geometry, the average strength for PU holds was 2149 lbf and for the 3D printed holds the average strength was 2599 lbf. Below are more details: - Using a 3D scanner the 3D printed climbing holds were geometrically identical to the traditional PU holds. - All holds were tested in a custom steel frame inclined at 20 degrees from vertical to simulate a climber pulling out and down on the hold. The holds were bolted as they would be on a wall and then tested in compression. Sample size for each hold batch was 5. - 3D printing material used was PETG. PETG is a very easy material to print using a consumer 3D printer and can be easily printed with, for example, the ~$300 popular Ender 3 3D printer. - Using surface textures, 3D printed climbing hold surfaces can be made sufficiently grippy and pleasant to hold onto. Feel free to ask me more questions but I thought all you DIY-ers out there would be interested in my results. |

|

|

Did you test other grips besides crimps? Any bigger, mini-volume sized holds that are super popular currently (hollow on the inside)? I'm curious about how they hold up long term as well. I wouldn't be surprised if we see a boom of custom small batch holds that have been 3D printed once the technology and material standards come into view. |

|

|

How many walls did you use? What were the infill settings (percent and pattern)? Did you find any favorite settings for the texturing/fuzzy skin? Sounds like an awesome study, thanks for sharing. |

|

|

Kyle Smith wrote: I tested crimp and jug style holds. The jug style 3D printed holds were only around 50 lbf or so weaker than the traditional polyurethane holds, on average. All of the holds I tested were 100% solid infil. I did not test how well they hold up long term, but my guess is that the 3D printed holds would do just fine. |

|

|

Branan Andreu wrote: I used 100% infil for all of the holds to get the strongest possible holds. Rectangular infil pattern. One could experiment with lesser infil and more walls but my analysis about this in slicing software was that lessening the infil only saved marginally on time and filament. Fuzzy skin at about a 1.5mm thickness worked well and was simple to apply in my Prusaslicing software. (Other slicers can do this as well.) One could also make small pyramids or "bubble wrap" texture on the surface of the hold. |

|

|

This is super interesting, thanks for the results! I've got a decient bit of experience with 3d printing, and have wanted to try making a hang board type setup with a few holds bolted to it. I might give this a try. This also gives me some ideas regarding 3d scanning real rock formations / holds and printing them..... that works a bit better than making a silicone mold on the side of the local crag lol |

|

|

I wonder how different texture options will compare to the texture you get with the standard foam hold molded into a silicone negitive technique usually used for polyurethane. I've always been quite impressed with how well that method works for getting a texture aproxamating rough rock grains. If I go small enough with the layer height on the perimeter walls of the print I might be able to get a fine enough texture... or maybe the corser 3d printed texture will be good just different. Definitely want to try this out and see. |

|

|

Kyle O wrote: If you had 2 identically shaped holds strong enough for climbing, one 3D printed and one PU, what would the material cost difference be do you think? |

|

|

For years now many holds from CX in Bulgaria, particularly their Dannomond plastic, have all appeared to be 3D printed or something similar. Those holds are always thinner (lighter) and more flexible, and in general, much better. |

|

|

Are there any issues/results related to the anisotropic strength of 3D printed materials? |

|

|

Billy B wrote: For crimps holds, PU holds go for about $6-7USD whereas 3D printed holds are about $3USD. |

|

|

Richard Randall wrote: This is definitely true and, yes, that is the case. I noted about double the strength in holds printed in the two principal orientations. Luckily, holds get stressed the most usually in one direction (getting bent out and down). It’s hard to make them experience much force in another direction, most of the time. |

|

|

Do you have the STL files on Thingiverse? |

|

|

What were your print times? PU holds can be made rather rapidly, multiple per day per mold. From my experience with 3D printing, which is admittedly limited, is that 100 percent infill prints take a long time to print. Another question, with larger holds like a protruding jug, the climber would impart a moment on the hold. This would result in compression in some areas and tension in others. Have you done any FEA on your models to see where possible stress points would be? There could also be regions that would have shear, if I am remembering my mechanics classes from a decade or more ago. Final question, do you have pictures of the tests? It would be cool to see the test setup and the post test failures. This is cool research that could really open up hobby hold making, especially with how easy it is to use a cell phone to make 3D scans. I have thought about making replica holds from some of my local outdoor climbs. I was planning to print the replica, make a mold, and cast them in PU, but it I can just stop at the print, that would be pretty cool. When you finish your final write-up, please post a link, it would be great to read. |

|

|

Do you have an images / diagrams / models? Would love to see a visual of the holds, testing set up, and/or data plots. |

|

|

what is the make and model of your printer? |

|

|

Sean Marsh wrote: Prusa Mk4S |

|

|

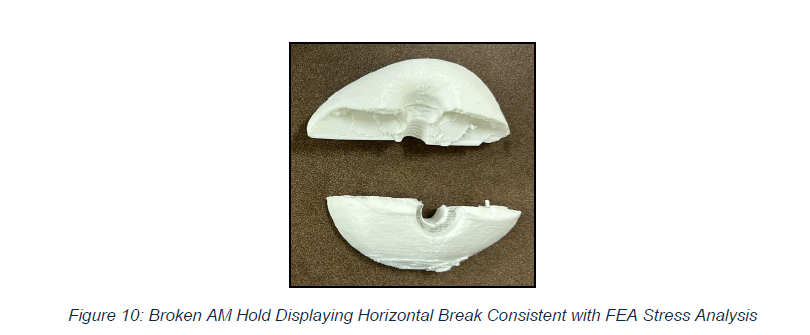

Above is some data from my study, set up, and breaking pattern of a 3D printed hold consistent with FEA. |

|

|

Shane F wrote: For a standard crimp hold my print time was 2hr 30min. For a large jug hold about double that. Both of those are using 100% infil. I've never made PU holds, but I'd say printing them is faster. I did an FEA analysis. See my above image of the climbing hold that broke. Stress is concentrated horizontally to the left and right of the bolt hole. The climbing holds indeed broke in that fashion. This happened with both crimp and jug holds. Directly 3D printing the holds is the way to go in my opinion. No need for a PU mold. |

|

|

Another thing to look at and test if you can would be the strength of the plastic holding the washer and how it holds up to over tightening. Typically holds break around the washer, which happens faster when there’s over tightening, poor internal structure on hollow backs, and/or not enough plastic behind the washer. |

|

|

Where the PU holds breaking in a similar manner as the 3D printed holds? Did you think of testing the printed holds with the print layers perpendicular to the mounting surface and the ground? It seems like that is a layer orientation that you missed. It would require a lot more supports than the other two orientations, however. |

Continue with onX Maps

Continue with onX Maps Sign in with Facebook

Sign in with Facebook