Drop in / Self drilling anchor removal

|

|

There have been several post referencing drop ins/ self drilling anchors in different forums, with many different strategies for pulling them. Over the last few months I've come across many of these, and the best way I've found to pull them does not require any specialized tools assuming that: The bolt doesn't break off, and it is the type where the sleeve is driven onto the cone (left), rather than a punch being used to drive the cone down into the sleeve (right). The punch set drop ins seem to be a more recent design, and rather uncommon in the field, but they would be very difficult to distinguish from the surface. Process: Squirt water into the the anchor as lubricant. Using a 1/4" or 3/16 sds bit, rattle on the cone with a drill in hammer only. The bits I've used had the carbide tip removed, and were cut down so the fluted portion of the bit is 2.5" long. My drill has a chisel/hammer only mode which is all I have used. For drills that don't have a hammer only, hammer drill may work. Being careful not to damage the threads, rattle on the cone for about 30 seconds. The cutoff 1/4" or 3/16" sds bit is the only specialized tool needed. The sleeve should vibrate up and out of the hole a small amount (1/8-1/4") once it does this, you can screw the bolt/hanger back onto he threads, and funk the sleeve out. If after rattling the sleeve won't easily funk out, squirting more water and rattling a little longer should break it loose. Carefully hammering on the edge of the sleeve from the side (not driving it in) or gentle side to side movement of the drill while rattling on the cone also helps the sleeve to vibrate out and loosen up enough to then be funked out. Before rattling After Rattling I have tried the push stud method developed by others with a bolt cut down on the tip used to simultaneously push on the cone and pul on the sleeve. This method works similarly well, but does require more tools and parts, and the specialized studs are fairly easy to damage, and have a tendency to jam. Core drilling also works equally well, but again requires more specialized tools. Last week we replaced 3 self drilling anchors, two were core drilled, one was pulled using the SDS bit. The core drill took slightly longer, and left a larger hole. All three methods are viable, but the SDS method seems like the quickest and easiest with the fewest specialized tools. The most recent anchor I was not planing for drop ins, and did not have the cutoff SDS bit in my kit. Unstead I used a 5/16 draw stud screwed onto an SDS spinner adapter. The process ruined the draw stud, but worked about as well as a small sds bit. This is the anchor from last week. Note the broken off drop in in the middle. Two outer took a 10mm stud, center maybe 6mm? Left and middle were reused, right was pulled and patched. |

|

|

Curious. Did those need to be replaced? |

|

|

Kauait wrote: The ones on the first pic are new and never placed. The rest absolutely needed to be replaced. |

|

|

Do you think this has any chance of working when limited to hand drilling? Is hammering on the cone with a hand drill likely to be effective at all? Otherwise: does anyone here have experience with removing spits by hand? Is it the same technique as removing buttonheads? |

|

|

Alex Fischer wrote: I don't think this would work well with hand drilling. The vibration seems to be more helpful than impacts to the cone. The push stud method would likely work better in this case. Trying to pull them like button heads doesn't seem like it would go well in most cases. The push stud seems like your best bet. |

|

|

Peter Thomas wrote: What is the push stud method? |

|

|

Peter Thomas wrote: I have zero experience pulling bolts but an old machinists trick to remove a blind bearing is to stuff some bread into the cavity and then hammer a punch that’s the same exact inside diameter in. The bread deforms and pushes out the bearing. Would this work or be helpful at all? |

|

|

Peter, I like this rattling method and will try it on self drives. Drop-ins function in the opposite direction however. The wedge is driven into the sleeve with a setting tool so I expect it will just get tighter from hammering more. I drill the wedge out of the sleeve using a 1/8" followed by a 5/16" cobalt bits. I used drill stops to set drilling depth to prevent hitting rock. The wedges are only 1/2 inch long so the the job takes 10 minutes or less. |

|

|

timothy fisher wrote: Tim, re: drop-ins. I seem to recall the CCC having very good luck pulling these (and a ton of them) with the Hurley tool up at Hidden Valley. If this is the case (maybe someone from the CCC can verify?) then it apparently works well enough that Peter's trick wouldn't be necessary for drop-ins. Curious if you've ever discussed this with Shannon? I believe he did most of that work at Hidden Valley. |

|

|

I ran into drop-ins, the punch kind, on a route I was rebolting this summer on Little Si. I pulled two with a doodad/Hurley, the third one snapped off and also broke the thrust washer on my bolt puller, and after that I didn't bother pulling the rest and I just patched them and moved the bolt. |

|

|

nbrown wrote: Yes, Shannon was pulling them directly out with a Hurley Junior. This worked most often, but occasionally cracked the rock requiring the bolt to be moved. On more critical bolts, where moving the bolt was not an option, he would drill two holes with a 3/16 inch bit alongside the bolt which allowed them to be pulled without damage. Then, a glue-in was installed. |

|

|

Andrew Jackson wrote: Yes in harder rock you would often just dinnerplate the rock or just break the drop in in two just pulling. My method works 100 %. |

|

|

Any tips for distinguishing between self drives and drop ins? There are a handful of bolts I'd like to replace around here that I've always assumed (and been told) were self drives, but now I'm not as sure. |

|

|

Drop-ins are usually 1/2" diameter and take a 3/8 bolt. Large self drives use either a 3/8" or 10mm bolt. The 3/8 self drives have been available in the US in 1/2 Outside diameter or 9/16 OD. If it is a large one with 3/8 bolt and 9/16 OD it is a self drive. If it is 1/2 inch OD it could be either. Drop-ins are normally placed with a power drill and were popular in the mid-Atlantic region in the 90s. If it is pre- power drill it is likely self drive. Smaller self drives take 5/16" or 8mm bolts usually. I have only ever heard of these having an OD of 12mm. |

|

|

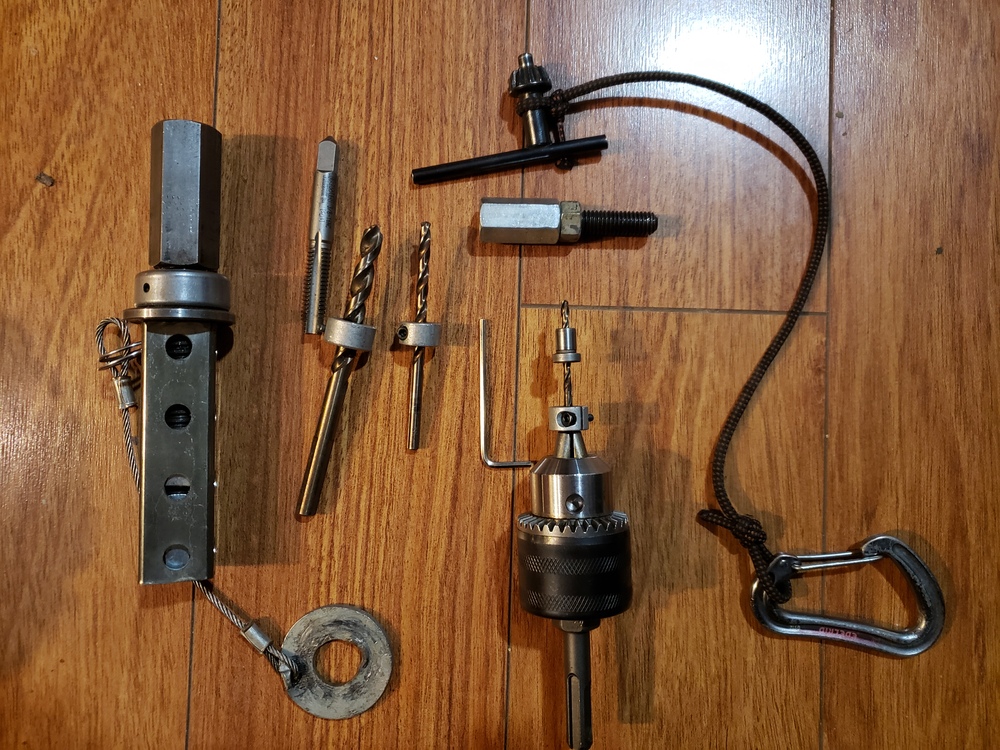

My kit for drilling out the expansion wedge from a drop-in. Included is a stubby doodad for pulling the sleeve after drilling out the wedge. In the chuck is a 1/8" bit with drill centering adapter and stop. I actually prefer a subcompact drill same battery as my rotary hammer for smoothest operation. The chuck with SDS adapter is a bit lighter though. |

|

|

George M wrote: The next time you could consider the methodology shown here: https://www.peakinstruction.com/blog/removing-sleeve-anchors-spits-etc/ I used that before I started using a push bolt. Works actually really nice and fast. We only seem to have the smaller self drives here, so two 3/8" beside each other do the job. Once you drilled it out for a glue-in (normally 9/16) there is not too much left from the original hole plus the two holes drilled below. If done carefully, most people won't notice a difference in between that and a newly drilled one as the only visual difference is the glue being spread out a bit further. In my opinion it looks better than having a patched self-drive close by and for sure much better than just having an abandoned self drive rusting somewhere close. Might look different with bigger diameter self-drives/drop-ins and I'm not sure about using a wedge bolt as a new one instead of a glue-in. |

|

|

Thanks Tobias, definitely will do that if I run into them again and I'm placing glue-ins. In this case, I was using ASCA-supplied 1/2" sleeve bolts so I had to patch the holes anyway as I could not reuse them. |

Continue with onX Maps

Continue with onX Maps Sign in with Facebook

Sign in with Facebook