Minimum Bolt Length for 3/8" wedge bolts in granite

|

|

I'm sure this has been discussed before on this forum, but I can't find a reliable answer online or here. What is the minimum recommended bolt length for 3/8" wedge or 5-peice bolts in solid granite? Is 2-1/4" long enough for sparsely traveled routes? YGD? |

|

|

Yes (it’s fine) |

|

|

Yes plenty strong. The Simpson 316 SS wedge anchor 3/8" x 2 1/4" is good for over 3,000 lbs in both shear and tension in granite (f'c around 15,000+ psi). |

|

|

Probably depends on what type of “granite” you are bolting. Our local rock is softer in some areas than the local limestone. I go with 3” in these cases. |

|

|

I agree with Dan that it depends on the granite. Featured granite with seams or weathered, large-grained granite with lower strength, you are going to want more embedment. 1.75" of embedment is pretty minimal and only saves a few quarters per bolt ... Keep in mind that the nominal length of wedge bolts is given as the total length (so that 1/2" sticking out past the hanger is less embedment) while the nominal length of 5-piece bolts is essentially the embedment depth (below the hex head). |

|

|

I used and sometimes still use 2-1/4 wedge bolts in granite. They are plenty strong. For a long time I was good with 1/4 x 1.5in split shaft bolts in granite. Those are plenty strong enough too… in the short term :-/ |

|

|

But why go minimum ? To save money ? Granite varies from gravel to bullet. Often at the same crag. |

|

|

jbak x wrote: Most likely hand drilling. |

|

|

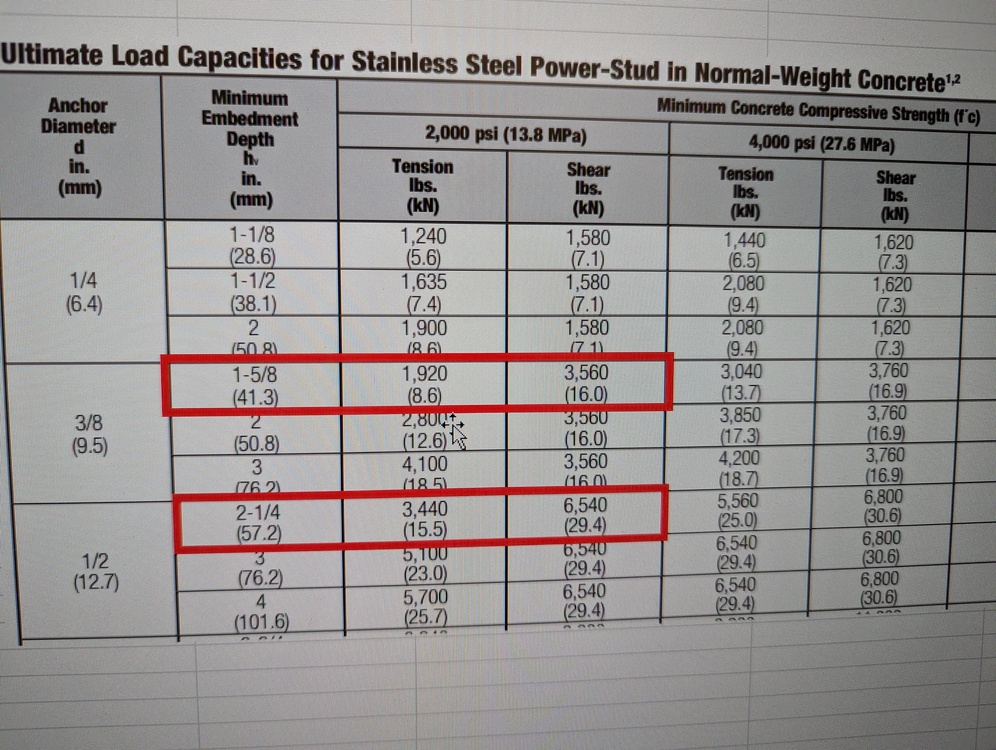

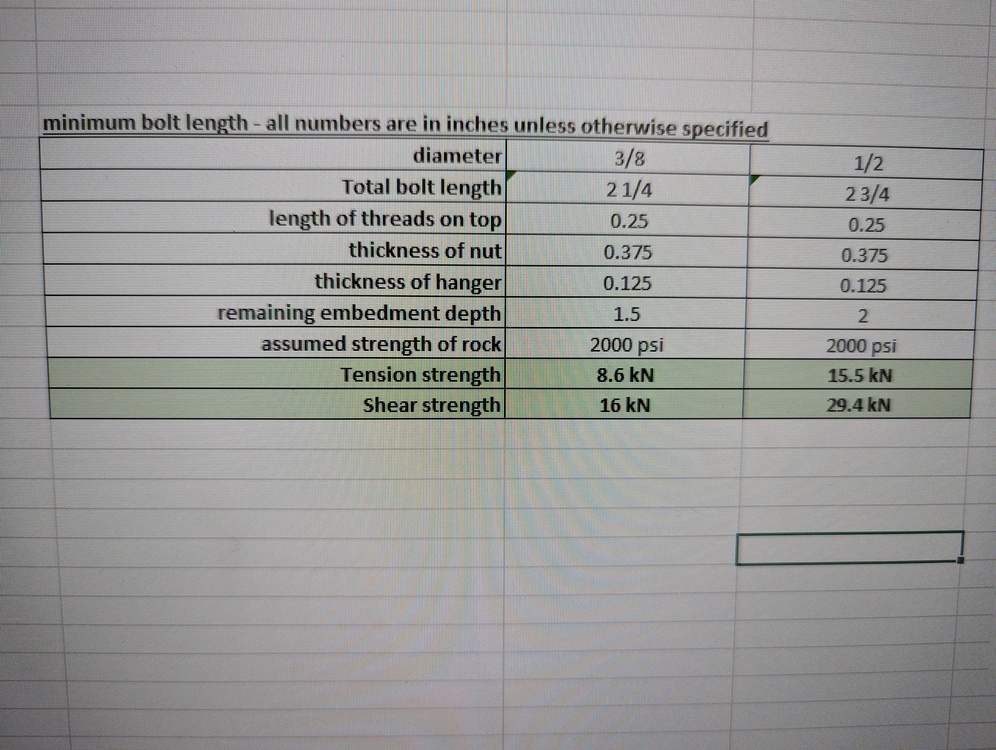

Hand drilling, extremely long approach, very long routes, minimal time. Btw, according to the specs I found for one wedge bolt, min embedment for a 3/8" bolt should be at least 1 5/8 inch....so a 2 1/4"long bolt should be ok for solid rock on less traveled / less fallen on bolts..... Interesting to note that they require more minimum embedment for 1/2" bolts DISCLAIMER: these numbers are all wrong and should never be used for anything |

|

|

Oh sure... Hand drilling... Duh. I've certainly become a sporto. |

|

|

No Face wrote: A 2 1/4" wedge bolt has 1 5/8" embedment if placed optimally (with no threads showing past the nut, just the top conical tip). If more threads are showing, there's less than 1 5/8" embedment. Bolt length for the short 3/8" bolts is somewhat confusing since the length of a wedge bolt is the total length of the bolt, while for a 5-piece it's the length of the bolt under the washer. So a 2 1/4" Power-Bolt (aka 5-piece) is about 2 3/4" total length for the bolt. Hand drillers know that you drill quite a bit deeper to place a 2 1/4" 5-piece compared to a 2 1/4" wedge bolt. |

|

|

No Face wrote: No Face, the specifications you are referencing are not providing you a minimal acceptable bolt length, as you have concluded. The specs are providing a range of strengths for the products (including various lengths) they manufacture. They show the shear strength of the bolt is not affected by embedment, but if you have a tension load (or combination of tension and shear), embedment depth does matter and the shorter bolts only provide about half the strength capacity. "Solid" granite is going to be much stronger than 2,000 psi, but it is unclear what your interpretation of "solid" granite is; a local mentor would provide more perspective and relevant advice. If your routes are slabby (mostly shear) and your "solid" granite does not have surface fractures or lower strength, you'll be ok for your first ascent. If you have some steepness and some rock strength variations, you'll probably be ok for your ascent, but your hardware may not have the expected factors of safety or longevity, especially if you are in Europe. If you do go forward, having a handful of longer bolts with you for the cruxes, locally-steep bolt placements, or if you encounter easier hand drilling, could be beneficial. |

|

|

What Greg Barnes said above is very important. The 2 1/4 SS "Powers Bolt" while slightly longer, are tried and true in many rock types. They are a bit harder to place if you are drilling from a free stance. They are stronger in shear than even the best wedge bolts. If you do go with stubby wedges i would recommend getting the best you can find. In my opinion that is the KB3 Hilti. |

|

|

timothy fisher wrote: Please forgive the tangent and what may be a silly question, but what makes one wedge bolt better than another wedge bolt of equivalent dimensions and grade? I’ve found KB3s to be a little easier to engage than Power-studs, but are there other characteristics that explain why one is better? |

|

|

The cheapest wedge bolts seem to have a steeper angle to the wedge and chunkier collars. They are easiest to remove in medium density rock because the collar acts like a bit in either direction when you spin the bolt- it cuts the wedge and it cuts rock if the collar itself spins. KB3 bolts have a more gradual wedge and a collar with tapered edges- there's a lot more surface area there. That makes it less likely to disengage and also difficult to spin effectively. Spinning doesn't produce a hard stair-step score line in the wedge because the rear edge of the collar is so thin that it doesn't damage the wedge. |

|

|

For sure this a tangent subject but a good one. To meet the 25kn standard a 3/8 wedge needs to have rolled threads. All KB3s look the same and you can tell at a glance that they have rolled threads. The same cannot be said for other bolts. Are cheap 3/8 wedges good enough? Maybe, but when using a 2 1/4" wedge i like for them to tighten imediately like the KB3 does. |

|

|

Thanks much, Gregger Man and Timothy—I appreciate the information! |

|

|

ryan laird wrote: This is what you see on the surface, but as the expansion cone is drawn into the sleeve by the bolt, the threads and stock of the bolt protruding past the rear of the expansion cone are no longer providing any additional depth. “Length” on either bolt design is sacrificial as the bolt is tightened. OP - A tip to getting studs/wedges set perfectly in softer rock for maximum depth is to remove the hanger but leave the washer on (as not to drive the stud too far into the hole where it is irretrievable), loosen the nut as much as possible, drive and torque the bolt, this will draw the stud out a few turns, now reinstall the hanger and torque again. This way the wedge is set without sacrificing too much length. You can remove the washer for even more of this effect but be very careful not to drive the stud too deep into the hole you just hand drilled! |

Continue with onX Maps

Continue with onX Maps Sign in with Facebook

Sign in with Facebook