Replacing Button Head Bolts

|

|

Looking for some tricks to replace an anchor that are old button heads. I don't have a tuning fork piton, but my thought was that I could use a carpenters hammer, and tap it underneath using the same method as the tuning fork? any other methods I should know about? |

|

|

|

|

|

Anna Brown wrote: This is more or less exactly what I am working with. I think they are smc hangers also. Ideally I would reuse the holes |

|

|

a beach wrote: Your thought of utilizing a claw hammer could work if you modify the slot with an angle grinder. Instead of the slot narrowing down to a sharp "V", the slot will need to be a "U" shape, 5/16" wide. Hardened steel faces should not be struck with another; do NOT hit a hammer head with another hammer. Shrapnel can result. The very best tool for the job is a 1" cold chisel with a 5/16" slot. Under $15, and 20 minutes to make one. Use a thin cut-off disc to make the slot. Grind the tips to have a more acute angle. Grind a groove around the circumference for a lanyard of 1/8" cord. Drive the chisel under the bolt hanger, between the hanger and the rock. If you are removing several 5/16" buttonheads, an engineer's hammer will make the job easier than a light climbing hammer. |

|

|

If you have access to one, or can make one yourself, a Hurley Senior is an excellent option for pulling button heads and other compression bolts. In Southern Arizona we are lucky that Geir is a local and has produced one for our local anchor replacement team. I used it just last month and pulled a series of button heads out with ease. It is more bulky and heavy than a tuning-fork cold chisel, but well worth it if you have several button heads to pull and want to avoid any ugly rock scars that can form when using a chisel.

https://www.geir.com/bolt-replacement/ instructions on the hurley junior, the senior is basically just a larger tube and attachment point (it grabs the hanger, not the stud). Perhaps overstepping, but Geir has been very helpful when I have reached out in the past. https://www.mountainproject.com/forum/topic/125425705/how-to-make-a-hurley-sr - an old thread, but perhaps could be revived. |

|

|

I’ve replaced several using a finish claw hammer. Find one that doesn’t have a very pronounced curve. The hammer I use didn’t need any modifications and so far has worked 100% of the time. Place the claw around the button head and strike the head with another hammer until you can lever it out. I’ve got a tuning fork but my go to is the claw hammer. |

|

|

It may also be helpful to use a "knife blade" piton or two to get things started. It can be challenging to get a chisel or hammer claw beneath the hanger if it is sitting flush or in a depression in the rock face. Starting with a knife blade can help with initiating the removal. Also, a tuning fork or hammer claw may not fully pull the button head stud from the wall. A funkness device is indispensable for the final pulling. Make sure you connect your funkness to the bolt hanger and to your wall hammer eye using quick links or other steel connectors, aluminum biners will bend and break when you're generating extreme static forces with a funkness. Take photos of the process, including your success and failures. Bolt replacement is a fine science and you can learn a lot from the myriad bolts and circumstances you will encounter. Plus sending pics to ASCA or Access Fund will make them happy and you might even get some hardware out of it someday if you keep it up. |

|

|

Those appear to be 5/16 Rawl drives / compression bolts. They can be very tight in the hole. With a pulling tool the hanger will sometimes rip off before the bolt moves. A better tool in my opinion is a chisel bit for a demolition hammer than has a thin tip and shallow taper like a knife blade pin. Eye protection and ear protection recommended! |

|

|

|

|

|

I had pretty good luck with a tuning fork. Once in a while the bolt failed almost immediately and nothing would work because the bolt was effectively rusted through. If you break of the bolt you should be able to use a core bit to reuse the hole. There is a thread on mtn project about that |

|

|

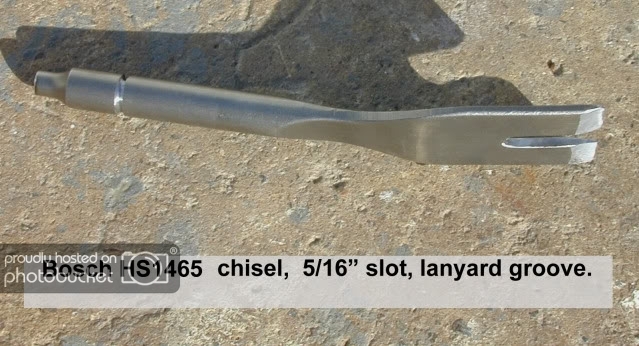

timothy fisher wrote: It has also been my experience that the hanger will rip before a 5/16" Rawl "Drive" bolt pulls out of good granite. The Bosch tile chisel # HS1465 ($14.39 on Amazon) is an excellent tool to initiate the bolt moving out of the hole. Then, the thicker 1" cold chisel will complete the extraction. |

|

|

ClimbBaja wrote: ClimbBaja - Regarding the Bosh tile chisel with the slot: I'm curious if you utilize your hammer-drill (in hammer only mode) or just tap with a manual hammer to initiate the bolt moving. Any issues with scaring and chipping of the surrounding rock? |

|

|

You can expect some chipping and scratching around the hole when removing compression bolts. This will vary with rock type and quality. Of course you are upsizing the hole which will remove some things. Usually this will not impact your new bolt. If you upgrade with a glue-in you can compensate for most problems. If you do have a significant rock fracture you will likely need to relocate and patch. The pictured chisels and "tuning forks" are all used with a hammer. A heavier hammer is a good idea. At least 20oz. |

|

|

Matt Sammons wrote: A climbing hammer will do the job. If you have a number of buttonheads to remove and carrying the extra weight is not an issue, then a heavier "engineer's hammer" is more efficient. The galvanized sheet metal disc with a slot (pictured above) helps to prevent scarring the rock. |

Continue with onX Maps

Continue with onX Maps Sign in with Facebook

Sign in with Facebook