Tying hollow block

|

|

Hi. I have a load of this and plan to turn it into prussiks. Two questions, any novel ways of sealing the ends after cutting, and what knot is best. Thanks |

|

|

David Coleywrote: Can you add a picture of “this”? |

|

|

David Coleywrote: Interesting - I didn't know it was sold from spools. |

|

|

I assume you are talking about the Sterling Hollow Block? The Sterling documentation states it shouldn't be used as your primary means of attachment to the rope. |

|

|

1. Splice it, don’t knot it. 2. Be very aware of the failure modes of braided aramid if using it as anything but a below-the-device third hand. The newer (black) hollowblock is supposed to be less vulnerable to this, but braided aramid can self abrade leading to failure under very low loads without obvious damage. @lecerfagile wrote: |

|

|

Eli Wwrote: Dang!!! Thanks for the enlightenment. |

|

|

|

|

|

David Coleywrote: Where did you manage to find that? |

|

|

Matthew Bellwrote: Sterling sells it for firefighting (for keeping track of position in zero visibility/ as a tagline, not for life safety loads)

|

|

|

That’s RIT 900, it’s flat from being spooled, but will return to round when loaded. Shouldn’t be as much internal self abrading as the Hollow Bloc. |

|

|

Brockywrote: I don't think the issue with the hollow block is self abrasion rather the cycle fatigue of the technora. The RIT 900 is made from Twaron which is chemically very similar to technora. (Technora being derived from two diamines and Twaron being from only one) Check this study out specifically the "bending flex cycle test" results https://user.xmission.com/~tmoyer/testing/High_Strength_Cord.pdf I would expect Twaron to follow a very similar cycle fatigue degradation as technora. Not trying to sow FUD here but something to think about for sure. |

|

|

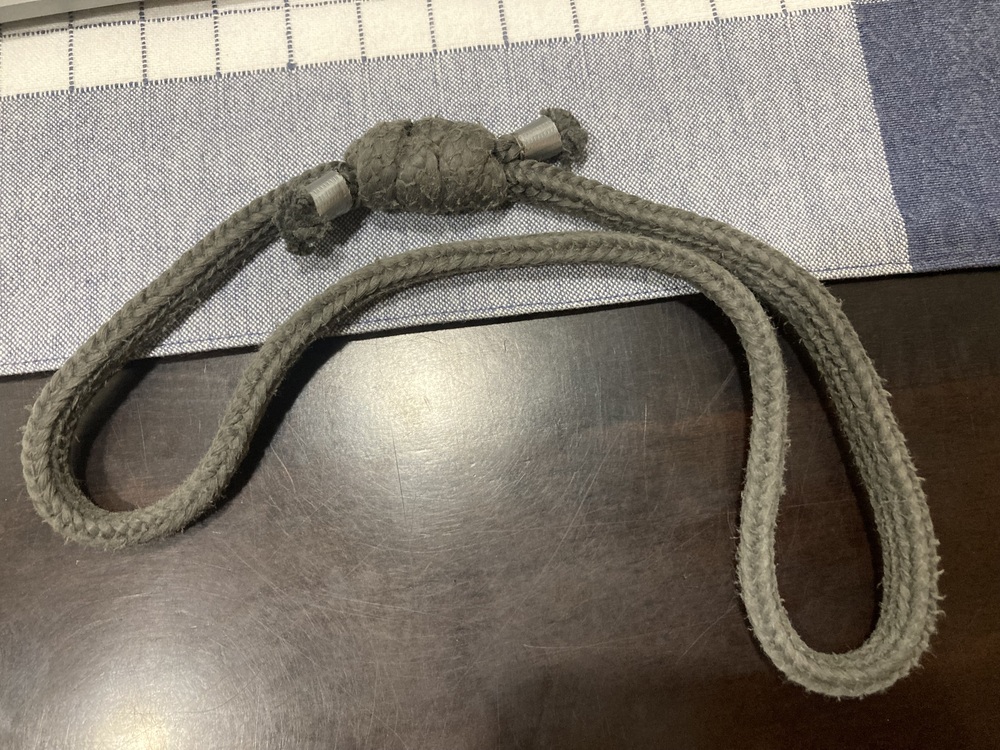

My custom samples of the Technora HollowBlock 2 are tied with a double fisherman’s bend with then ends taped. |

|

|

Eli Wwrote: The current hollowblock (hollowblock2) are made of a completely different fiber now. I don't think any of the information you posted is relevant at all. |

|

|

It's a little worrying that posters are looking a braided tan cordage and making enormous assumptions about the cordage and the fibers it's made of. Without any actually certainty of what the cordage actually is. You cannot make a distinction between fibers types with a compressed image over MP. |

|

|

Danielwrote:'aramid' is a nebulous term that encompasses nearly all fibers used in climbing soft goods. Not in my realm. I wonder why you would imply that people think aramid and nylon are the same thing. |

|

|

Mike Gibsonwrote: I don't recall making that statement |

|

|

Eli Wwrote: Invisible damage is one of my biggest concerns in making DIY soft gear. I just don't know how it will weaken as it ages, because the available data may not reflect my usage patterns accuracy. So I've decided to commit to randomly break-testing some of my own pieces, every year. The last few months, I've made a couple dozen slings (mostly trad pieces).. I tag & date everything, and I set up a calendar schedule going a few years out. The idea is to randomly pick out & break about 1-2 pieces a year, and measure how they hold up. It's kind of a lot for a DIY garage project, but I couldn't think of another approach that would have a chance at detecting any significant weakness trends. |

|

|

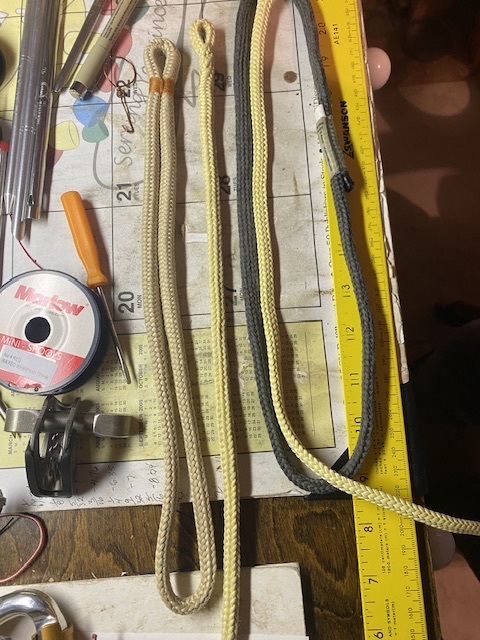

Matthew Bellwrote: Twaron and Technora are both aramids, but Twaron is more closely related to Kevlar, both self abrade more than Technora, as stated in the study you referenced.The Hollow Block is specially braided to be flat, unlike most 12 strand hollow braids. The Hollow Block is next to the RIT 900 below. Agree that splicing is the way to go, neater and retains more strength than knots. |

|

|

I've never spliced. Might anyone have a link to a video suitable for this material, please. And the size of spikey thing I'd need. Thanks |

|

|

Please keep in mind: |

|

|

Desert Rock Sportswrote: Speaking of redundancy this is what I use. Technora sheath with a nylon core https://www.rocknarbor.com/product/ape-canyon-outfitters-6mm-trc-eye-to-eye-hitch-cord-23/ |

Continue with onX Maps

Continue with onX Maps Sign in with Facebook

Sign in with Facebook