More splicing discussions?

|

|

So it's been a few months since I started that other thread about splicing Amsteel (12-strand hollow braid Dyneema rope) as an alternative to tied or sewn slings/runners on climbing gear... Said thread just zombie-reanimated itself and got derailed into a truly R-worded meta-argument about safety to literal zero useful purpose. So I figured I'd give an update on how I've been passing the time -- and maybe even find some other folks interested in this kind of rope craft? Anyway... Since January, Ryan has managed to:

It's been fun as hell -- and YES, I've built a few pieces of gear on which I've taken actual, no-shit lead falls IRL. If anyone else on here is interested in this and related topics, I'd be happy to see where our discussions lead. |

|

|

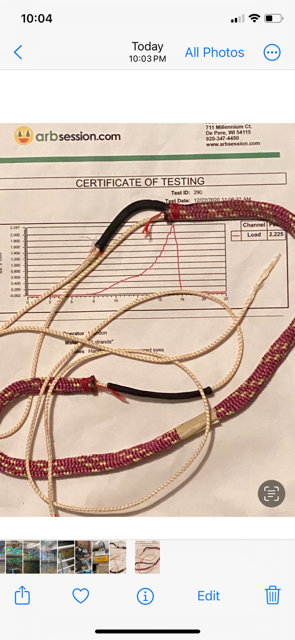

A small sample of past splicing, mostly for tree work. Testing was done by using them to rig down tree parts, sometimes ff2 with several hundred pounds of weight. The black, red and white rope is a 16 strand arborist, the cover takes most of the load, with the core strands acting mostly as a filler. Bottom three are more recent, Newt from HowNot2, and the PUR and Rad for friction hitches. |

|

|

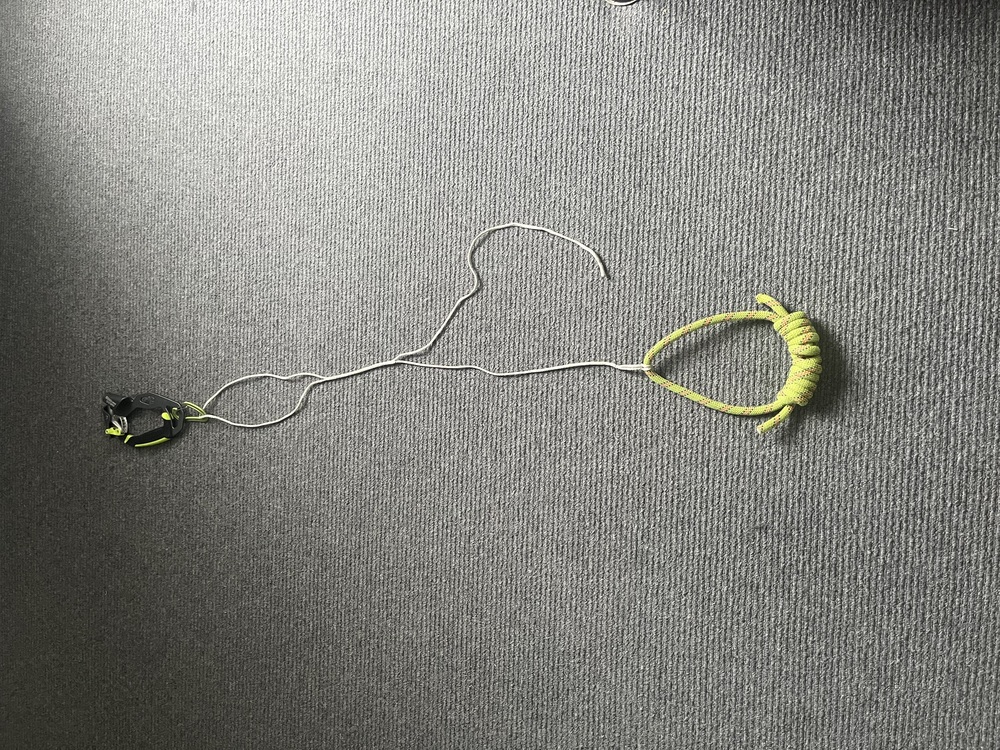

Ryan, I’m a climber, (mostly solo), a safety professional for my entire adult career (~20 yrs), grew up in backwoods Appalachia playing in the woods and trees with ropes and whatever I could tinker together… bought a set of ascenders and an 8 in Charleston WV in the 90’s but had to make my first few harnesses because they didn’t sell kid sized ones. Here’s a picture of my first daisy( still have it for sentimental reasons). As a kid, not regularly exposed to other climbers, I didn’t know something like a daisy chain even existed, but I knew I needed adjustable length tie in points. I am absolutely here for a conversation about making gear. I wouldn’t take the daisy pictured above out on a wall now, but it worked and I hung on it many times. Instead I’d use my heavily modified Camp Swing ( see comment about making gear). I saw that last thread get “zombie-reanimated and derailed into a truly R-worded meta-argument about safety to literal zero useful purpose” and was disappointed because I’d hoped it would be a productive conversation. As a safety professional, I’d never let the guys at my plant use homemade gear in the workplace( lawyers, OSHA, liability, etc…) But I’ll happily trust my life to gear I’ve made. That’s an informed decision based off of 30+ years of making things plus a couple decades evaluating safety systems, doing risk-hazard analysis, and learning how equipment and materials work. I hope this conversation can stay positive and productive. Maybe some of the LRS/TRS community( myself included) can keep it on track. Soloing doesn’t strictly require making gear, but it does mean using gear in ways outside of the designed purpose, and that’s practically the same thing. So to get back on track of making gear, a while back I was looking to add a second belay loop to my harness. At the time I couldn’t find good data on making a continuous dyneema loop so I used a Petzl 30cm dog bone and a DMM small shackle. It worked great, and in my evaluation was “super good enough”, something around 20+kn. I taught myself to splice dyneema recently for the guy wires for my freestanding backyard climbing wall. I can see lots of potential for customizing gear as materials and knowledge become increasingly available. Yes, there is risk, and definitely YGD if you step one inch outside of strictly accepted practices… ok now that’s out of the way… Hope to see other like minded folks chiming in. |

|

|

TThurman wrote: There are definitely some people here interested in productive conversations -- and also plenty of the other kind of people. Unfortunately, the ratio around here is not real good, and the quality of the conversations has been limited. For PPE-oriented ropework, I've found MUCH better forums on Facebook and sailing websites. Reddit has a pretty good rigging forum, but not much on DIY PPE gear. I would love to be proven wrong. But so far, I just don't think MP has enough people with splicing skills, experience, and interest. Tell you what -- maybe we can each post a few bits we've made, and attract some more productive intent?

So far, most of my PPE splices are gear slings. I started with mostly plain continuous loops, but then got into soft shackles. End-to-end loops are great. One thing I came up with that I'm sure isn't an original idea -- clear heatshrink tubing to cover splices and high-wear areas. Makes things easy to inspect. Also helps lock down bury splices, but I'm not sure if I trust it without a Brummel or whipping stitches. Recently, I started making snow picket slings that are kind of a soft-shackle variation... Basically just a button knot stopper through a drilled & chamfered hole in the picket, and an end-to-end splice between the two loose ends so that the button has two bights coming out of the bottom. Way lighter & stronger than the steel wire on my Yates pickets -- and I'm using skinnier cord that cuts through hard snow easier. The dyneema cord will definitely wear out faster than steel wire -- but it's so cheap / easy to inspect and replace it. One of my big realizations is just how STRONG dyneema is when it's spliced... It really opens up a lot of possibilities. |

|

|

Ryan Lynch wrote: Oh, almost forgot -- I've slung some aid hooks and Tricams with dyneema... The aid hooks seem to work pretty well with stopper knots, kind of a shorter version of what I did with those snow pickets. Works pretty well. The Tricams are more of an experiment -- multiple end-to-end loops in parallel, with heatshrink tube to stiffen them up. Not sure if I really like it yet, but it's strong AF. |

|

|

Ryan Lynch wrote: I have Tricams overdue for a resling and I have often considered splicing something. Tricams are tricky to resling, especially small ones. I was concerned about how the narrow pin creates a small bend radius un the dyneema, but that's essentially not a major issue because lots if loops provide a good margin. The heatshrink you used, did you heat it? I'd be weary of heating dyneema. Also racking is a issue, the final solution needs to be tidy so as not to tangle while racked. Let us know how you get on. I climb in a maritime climate, so my pro. gets wet and needs drying. I hate encasing soft material in a tubing, like heatshrink. How can it dry in there without air? My gut feeling around drying isn't good. I could be wrong. |

|

|

Noel Z wrote: You're fine

Dyneema is super popular for it's use in maritime environments, the main use of dyneema is probably in ship tow lines(per ton of dyneema), so once again, you're fine. |

|

|

Can’t trap much moisture in the shrink wrap as dyneema is nearly waterproof. Clear shrink wraps has been around awhile, I started using it about a quarter century ago(sounds more dramatic than 25 years). The shrink wrap will melt before the dyneema, an indicator too much direct heat was used. Ryan, did you splice the ends together on the multiple loops for the Tricams, I have done the same, but for hitch cords, to make them totally flexible from eye to eye? I had some tested and they weren’t as strong as I calculated. |

|

|

Noel Z wrote: I used a temperature-controlled heat gun, and soaked the dyneema with water beforehand. I break tested some SK-78 & SK-99 after subjecting it to this treatment, and it didn't seem to impact the strength.

The heatshrink is snug, but not airtight. The Dyneema fibers seem to wick the moisture out, pretty effectively. I usually dry my gear by hanging it over a fan, but I live in a decently warm/dry climate (SoCal). |

|

|

Brocky wrote: That's basically what I've done, so far -- multiple loops with an end-to-end splice. I can't find the link RN, but there's a HowNot2 video where they make & break some sailing dogbones / strops using this method, but with chafe cover instead of heatshrink. The strops broke at significantly lower force than the simplest theory would suggest, but I don't recall the entire discussion about why. My break tests with these have been inconsistent, which is the main reason why I'm not sure about this approach. I could just go with more wraps, but that seems risky without understanding exactly why practice diverges from theory. |

|

|

Ryan Lynch wrote: I engaged with you in good faith (as professional in topics you sought information) with you, and you dismissed most of what I said. |

|

|

Mr Rogers wrote: We seem to have passed the point where your participation here is creating anything for you, except more negative feelings. And, I admit, I'm not particularly interested in hearing from you, either, going forward... No offense, but you don't seem interested in letting bygones be bygones. There's a little checkbox on every thread on this forum where you can "unsubscribe" from getting notified of any more updates to the conversation. So here's my suggestion... Unsubscribe yourself from this thread, and let's go our separate ways? Maybe we can both enjoy this forum better, without butting heads anymore. |

|

|

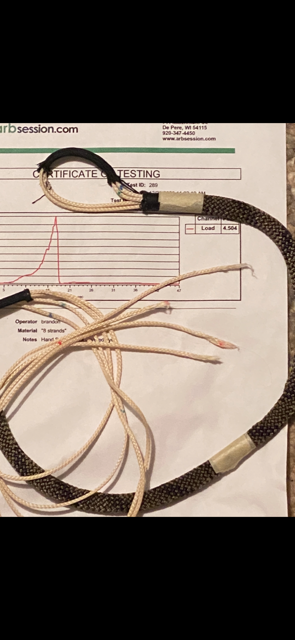

A couple hitches using 1.75mm Vectran in multiple loops. The first is two loops, with four strands between the eyes, the second is four loops. The Vectran’s break strength is 800 lbs, a 1.8mm dyneema cord has a 1000 lbs bs. I could have used more loops, but then it would be too stiff for a friction hitch. Last picture is a couple hitch cords and Blue Ice’s double eye, which uses the same concept. Also shown is a simple device for getting the correct length of core strands. |

|

|

Tree companies have been using heat shrink on splices for awhile. Like a decade or more. Most ropes/slings/prussics come with heat shrink on one or both sides of the rope. It’s much more commonly found on sewn splices as a method to protect the threads from wear and tear. No real benefit to use on a normal splice. I dunno why so many ropes come with it on one end, either. Maybe to help with making clean cuts.

Shrink wrap holding moisture is a non issue. It’s like 4” of rope, tops, and water can evaporate put either end no problem. |

|

|

Some versions of shrink tube have glue that would keep more water out. |

|

|

What are you guys' thoughts on abrasion? I'm just dipping my toes into dyneema, and the main use I have so far is a soft shackle through my harness tie-in loops to a swivel, which then goes to my Taz LOV3, which I use for LRS and TRS. It's a 5mm SS, and it's starting to show some light fuzzing on the diamond knot. I wonder at what point one should start to be concerned. Of course the knot doesn't have any structural role except to prevent the noose from going over it. |

|

|

Years ago, I traded a friend some gear for an old style #4. He’d done a dyneema splice for the sling. It was kind of nice since he doubled it up to allow for extension. At the time, he had a pull testing rig at his house and he had tested many of these type of splices. I don’t remember the exact numbers but it was plenty strong. I want to say it was stronger than the original nylon that Black Diamond used, but I can’t remember. I’ve whipped on it. More than a few times. I felt that side-eye from other people was a bonus. It’s about time to get a bunch of my cams reslung. I’ll probably go with nylon this time, only because of the simplicity of companies that do it. |

|

|

I’ve slowly been getting into splicing and I’ve mostly been making stuff like soft shackles for my slack line and an adjustable foot loop for my ascender. Until I have some way to test my stuff I think I’ll stay away for the PPE equipment. In the meantime, does anyone have any cool non-PPE uses for splicing? Also could someone send me a good online resource for making eye-to-eye splices like Brocky? Cheers |

|

|

highaltitudeflatulentexpulsion wrote: Did either of you manage to get a fast-pull drop test measurement? My setup works fine for winching slowly, but my dynamometer is a cheap crane scale, so it has a pretty slow sampling rate. Pretty useless for drop tests. I would love to figure out a way to get relatively accurate force measurements in drop tests, without shelling out $$$ for a LineScale or whatever. |

|

|

Brocky wrote: I sometimes use this kind of heatshrink for capping rope ends, where it wouldn't bear loads. Super great at resisting wear. I did check the MSDS for the product I was using, and chemical compatibility seemed OK for all the listed ingredients, at least with nylon & dyneema... But I still have some reservations of whether all those ingredients would still be mostly harmless at elevated temperatures. Also, I have some questions about whether the hardened glue will change the distribution of strain in the rope fibers. At any rate, I'd like to do some break tests to see how the glued heatshrink behaves... And to test if CA glue under regular heatshrink causes any problems. If you've got any data or theories on this, I would love to hear them. |

|

|

The glue in heatshrink is typically the equivalent of hot melt glue. |

Continue with onX Maps

Continue with onX Maps Sign in with Facebook

Sign in with Facebook