Bolting Starter Kit -- Feedback for an Aspiring Gumby Bolter

|

|

Howdy y'all, I got a wild hair the other week and, after crossing my 1000th pitch mark, decided it might be time to take a look at what goes into bolting a new route. I'd always flirted with the idea that it'd be really fun to learn to bolt eventually, but I always disregarded as a bad idea for someone with my experience level. I thought it could also be a good way to give back a bit to the community. So, I went down the bolting rabbit hole. The rock at this crag is volcanic, and I think would definitely be best served by using glue-ins. I was intimidated at first by glue-ins, but the more I've read the more comfortable I'm feeling with it. I think I'm going to use wave bolts for the first couple of routes. 1. What does a full starter kit look like? Here is kinda what I'm thinking currently -- what am I missing?:

EDIT: Adding new suggested gear to get by community.

So ALL-IN for just the tools and general materials I'd need to bolt my first 2-3 routes, I'm thinking it'll be close to about $400. That's not crazy bad -- I know I'm cheaping out a bit on the drill, but I'm comfortable with it for getting started. Seems like I could do a 2nd battery, but I think the 8ah battery will definitely get me through 1 route a day. 2. How the hell do y'all minimize costs? Specifically:

Holy shit -- bolting is expensive. I've got a new found appreciation for long term developers. How do y'all fund it? Is it always just out of your own pocket? 3. Is there something else I should do or any other big facts you feel I should be aware of before I go and bolt my first route? I'm open to any feedback or suggestions regarding this and would love to hear any pro tips or things you feel you learned over the years while bolting. Thanks! |

|

|

Paper towels are not free. |

|

|

It's not that expensive compared to other hobbies. People spend tens of thousands on cars, bikes, triathlon fees etc. I used to spend a similar amount of time and money when bike racing was my main sport/ hobby. Usually, new route development is out of pocket (as it should be) and community funds go towards rebolting efforts. A lot of rebolting ends up being out of pocket, too! A few opinions after reading your list:

|

|

|

Good on you for wanting to contribute. If nothing else, a few days of bolting and cleaning will deepen your appreciation for the routes you climb (and give you a 6th sense for sketchy rock/hardware). A few considerations that might figure into your calculus: First, 8Ah might be overkill. 4Ah gets me 12-14 3/8 x 3.5" holes in local basalt. If you're dealing with something truly soft like tuff, you'll get more mileage than that. if your crag is as chossy as mine, 12 holes means several hours of cleaning and, thus, a full day. Consider adding a large crowbar, a geology hammer, and a hand broom to your list. The cleaning is usually a lot more work than the bolting. If bolting on your way down, clean well between bolts so you don't catch a rock on your head. Oh, and don't drop a rock on your foot, and keep the rope off the ground! If the rock is something hard like basalt or rhyolite, you can likely get away with wedge bolts--way cheaper and less required gear. And if the crag is getting buried soon, you might not need to worry about corrosion resistance so much. An experienced local developer should know best. This will surely raise some hackles, but quality all-thread is cheaper than factory glue-ins, and just might exceed the lifespan of the crag. In super-soft tuff, a burly 8" piece of all thread is confidence inspiring. If you're bolting something wildly overhanging, you'll likely end up "downward aiding" to fix the rope. Here, a beater trad rack, some pitons, and sometimes some cheap 1/4" bolts might be required. This is a scenario where an initial run with removable bolts would make good sense (assuming glue-ins are necessary). I'm no glue-in pro, but am also wary of a glue-in that must be hammered in. I like the option of twisting the bolt around in the hole to ensure optimal mixing, contact with pocketed rock, and like to have the option to add more glue. For these reasons, I also like a slower-setting glue. And remember that no good deed goes unpunished. No matter how great your work is, someone will disapprove. Posting a route on MP is an invitation to every gym climber on earth to visit your crag and complain that they can't clip the bolts, the hangers should be painted neon, the aluminum anchor biners aren't fit for TR gangbanging, there's a death block 20' left of the bolt line, etc. |

|

|

Logan Peterson wrote: ^^ This right here |

|

|

Wow all around stellar advice -- I've noted a couple of big things I'll change. - @Logan Peterson -- Gonna add a crowbar, geology hammer, and hand broom to my list. What size/weight do you typically like for the geology hammer? - @Logan Peterson -- a couple new routes have gone in the past year, and it seems like the ethic has been to use glue-ins. I'll definitely reach out to some of the local developers and get their opinion. - @Jim Day -- LOVE the idea of doing a lead before actually committing to placing the bolts. At the very least, I'm going to drill all the holes and climb it on top rope while thoughtfully considering the clipping stances and bolt placement as if I were on lead. -@Jim Day -- Interesting - you don't think a balloon pump with a rubber hose attached and duct tape would work well? I read a couple people in other threads saying that worked pretty well. I was definitely trying to avoid the $80-$90 for the hilti pump. Keep 'em coming! |

|

|

14 oz Estwing rock pick is nice. Does everything a regular hammer does, and the pick end is great for detail work (just resist the temptation to make new holds). For blowing out holes, I really like the stiff black plastic hose they use to run water to evaporative coolers. Cheap at hardware stores around here. |

|

|

If you get the Bauer Drill a 5ah battery is more than enough fir a single route, even two routes. No need for the 8ah unless you are hiking in and only want to bring one battery but I would consider bringing two 5ah batteries anyway. Unless the rock is super soft crap mechanical bolts, either edge or 5 piece should be good, make sure they are stainless. |

|

|

I'm mainly saying that if I plan on bringing anything bulky, I prefer to have a purpose-built blow out pump. I wouldn't bother with the hassle of bringing a balloon pump, because I think you'd be just as effective blowing through a tube, which is usually good enough, just takes longer. |

|

|

I agree with Jim Day about the Hilti blower. I use one, and it's worth the cost. I recommend doing some rebolting work with someone experienced first. Rebolting helps develop work-at-height skills, understanding of good and bad placements, rock quality, tool use and techniques, etc. Just a thought. |

|

|

Brian Murphey wrote: I second this. |

|

|

A couple thoughts.. It's a good idea to practice on a random rock in your yard or someplace to get a feel for the process. If the rock is suitable, I'd also consider using wedge bolts as recommended above. What is the rock type at this crag? If you are doing a lot of work on rappel and TR solo on the potential route, a beefy static line is a very nice thing to have. And/or an edge protector I've found to be pretty key. Sometimes it will most likely take longer than 1 full day to bolt a single route. I imagine the Pacific Northwest to be similar to the Northeast as far as the prevalence of moss, lichen, greenery etc... cleaning can be pretty intensive. I've often spent a day scrubbing a route, then come back a week later after letting the wind and rain clear away some of the dust. Your kit will likely change as each route has it's own demands. A crowbar, for example, is not always necessary and is a lot to carry... some big stuff like that I bring out and then leave stashed at the cliff. I recommend always having a spare drill bit in your pack. They do break/wear out and it sucks to be halfway through drilling a route and not finish it. And, here anyway, all the expenses are out of pocket. It's truly a labor of love.... Best of luck! |

|

|

An adjustable daisy with an aid hook on it has made my life significantly easier for cinching myself into good bolting positions. This is what my setup looks like: |

|

|

Again, super appreciate all of the insightful feedback! |

|

|

Perry Gowdy wrote: You'll enjoy that drill. Surprisingly good quality. I have a Milwaukee but never use it anymore because I like the Bauer better (I have two). I haven't tried their blower but I'm sure it's as good as the M18 that I have. Depending on the terrain you're dealing with, a blower can potentially save you an enormous amount of time. Well worth the money, IMO -- I should have gotten one years ago. |

|

|

A lot of good advice in here and glad you're turning to the established route development community to get some feedback and advice rather than just winging it. My one hot take is that you shouldn't place a bolt that you don't know how to remove, largely due to Jim's points. I think Brian has a great take on getting started with rebolting first. It also gives you a good reminder to not skimp on good hardware that you're installing as well. Lastly, here's just another resource to read on getting into it all - something I compiled last year that I think has some value, though you've likely already gleaned much of it from your research already Good luck and have fun! Edit: one more callout that hasn't been on here yet - ear protection and a buff or mask or something. Breathing in rock dust is real bad for you and rotary hammers are god damn loud, especially if you're leaning close to them when drilling. I just use a buff and airpods but I've used OSHA certified masks and hearing protection before too - generally just depends how hot it is out and how much space I have in my pack. |

|

|

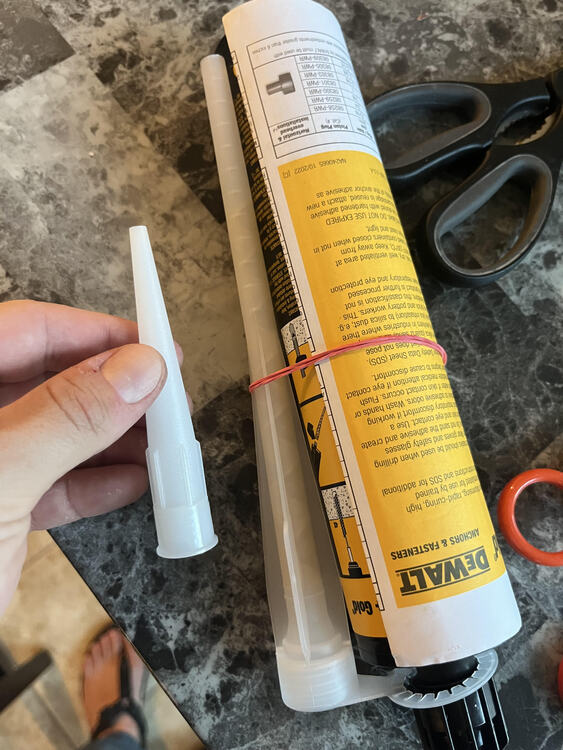

Hey, reallllllly dumb question-- but I have to ask. I ordered a large bag of these small caulk gun extension tips as extras for my glue so that when it dried out I could just dispose of it. They seem to be quite a bit different from the mixing tip that actually comes with the glue. Can I use these on top of the mixing tip? Will that allow me to just swap out the extension in case the glue dries up? What do y'all use? Here's a link to what I bought on Amazon: https://www.amazon.com/dp/B08Z3592V8?psc=1&ref=ppx_yo2ov_dt_b_product_details |

|

|

Perry Gowdy wrote: The glue mixes proximal to that, so no it won't help. |

|

|

nbrown wrote: That's what I was afraid of -- do you have a recommendation on how to combat this? Do you buy extra mixing extenders from somewhere? |

|

|

No way to combat it that I am aware, other than to have spare mixing nozzles on hand. The epoxy mixes in the nozzle, so it hardens in the nozzle. Once that happens, toss it and screw on a new nozzle. To slow the gel time, put the tubes and nozzles in an ice chest or bag ( I use an Ice Mule with a couple frozen water bottles so I can drink, or pour out, the extra weight after gluing). Keep the glue and nozzles at or below 50F, and the glue won't harden so quickly in the nozzle. |

|

|

Those nozzles are going to be useless for you. The only time I can think of where you would need that is if you're trying to extend to dispense glue into the back of a deep hole, but even then you'd be better off using a soda straw (especially since it looks like those nozzles are .5" wide, and *most glue ins require a .5" hole or smaller). You'll want to buy dewalt's spare nozzles, like these: https://www.toolbarn.com/products/powers-08293?variant=40163492233413&gclid=CjwKCAjws9ipBhB1EiwAccEi1HJiY1hxX76IInZIkU_1Qsh6flre11disf9b_6jdQYmmadot27tpgBoCgNwQAvD_BwE I know people love ac100 because it's inexpensive, cures in a wider temp range and is readily available, but in my opinion, a pure epoxy like liquidroc 500 is worth the extra cost for it's longer working time, you won't burn through as many spare nozzles. |

Continue with onX Maps

Continue with onX Maps Sign in with Facebook

Sign in with Facebook