Knots in dyneema -- rope/cord vs sling?

|

|

Several times in my climbing experience, I've been taught by instructors to assume that any knot reduces the strength of the rope/cord/webbing/textile by ** 50% **. The actual loss of strength varies, because it depends on the type of knot and the type of textile. Seems like most everyone is also aware that pull tests in dyneema webbing have demonstrated even BIGGER strength losses due to knots. HowNot2 (~3y ago) observed a 60% strength loss in Mammut 8mm slings carrying a single overhand knot, and similar results have been obtained by plenty of other testers. But the admonition against knots in dyneema (by climbers, anyway) seems to be largely phrased specifically around avoiding knots in dyneema *slings* -- as opposed to other textile structures. The focus on webbing might be taken to imply that knots in round rope/cord made from dyneema is less of a problem. HowNot2 (~7m ago) also tested knots in amsteel (braided dyneema rope) with similarly dramatic (>60%) strength loss. And the manufacturers of that kind of rope do generally warn against knots -- splicing is the only recommended technique, because it doesn't weaken the rope nearly as much. I can find some other scattered references online of warnings against knotting dyneema in other forms (round rope/cord). But it's just not nearly as loud & clear of a message as with webbing/slings. Recently, somebody even suggested that I should use tech cord (=dyneema or aramid) over dyneema webbing for knotted slings -- because he was under the distinct impression that knots in dyneema tech were A-OK. I guess what I'm saying is... The evidence seems to suggest that knots in ANY dyneema textile product are going to weaken them by *more than* 50%. That would be a dangerous assumption for climbers who have been taught that knots can reduce rope strength by *UP TO* 50%. At any rate, I definitely plan to change the way I talk about this with other climbers, and take a more skeptical approach to the assumptions underlying any recommendations on using tech cord, in particular. (Looking at you especially, Trango Big Bros...) Also, a footnote -- plenty of folks have tested and tabulated the strengths of a wide variety of *knots*. But most of the data I've found seems to focus on either nylon climbing gear, or other rope materials, and not much on Dyneema. In particular, I'd love to get a hold of pull test results on a wider variety of knots in dyneema, in order to figure out a reliable bend for joining textiles that can't be spliced. Thanks for reading this whole essay! |

|

|

One take-away from How Not To that maybe you missed is that any strength over, say, 15 kN is "super good enough". Your body will break before the gear. And I believe loops in tech cords tied with the manufacturer suggested knot (dbl or trpl fisherman's) are in that SGE range. No one ties Dyneema webbing sold off a spool into loops. At least I hope not. |

|

|

The old DMM video is the most missinterpreted pice of information ever. No matter how many knots you place in your dynema sling, they wont kill you. And they do not add together. You will however die, but not from the knots in the dynema sling... |

|

|

Gunkiemike wrote: Re: Super Good Enough... I would be happy with something that's reliably better than 10kN for the slings. BBs are rated at 12kN, and I've got some big cams @14kN. Re: Nobody tying dyneema webbing... Most cams have sling holes that are plenty big enough for 1/2" nylon tube webbing. Unfortunately, Big Bros have much smaller sling holes. Even if you could cram 1/2" nylon through the hole, would it perform well, when it's all bunched up? So I guess Trango recommends 6mm cord (not 5mm like I mentioned elsewhere -- I was mistaken) because that's the biggest that will fit. If they'd designed it with bigger sling holes, I assume they would recommend thicker webbing, like most cam slings use. |

|

|

How do you feel about cyclic fatigue in synthetic fibers? It’s not the single knot you need to be worried about, but repeated tying and loading of knots in the same spot…over and over. Data shows this can also reduce the strength of some synthetic fibers by as much as 50% in as little as 200 bending cycles. There is a pretty good ITRS paper on this topic from several years ago, but I can’t find it at the moment. |

|

|

Had an interesting conversation about knots in slings at the Petzl Institute WAH course. It certainly depends on your application, but they recommended using a basket hitch with a carabiner over knotting or girth hitching a sewn dyneema or nylon sling whenever possible. The knot weakens the sling by at least half, bringing a (e.g.) 14kN sling down to 7 or less. Adding multiple knots does not weaken the sling (or rope) further than the first knot, so the weakening affect does not "add up" with additional knots. Interestingly enough, they explained doubling the sling up in a basket hitch will actually increase the load capacity of the sling. Kernmantle ropes are generally rated for much higher levels of force, so adding a knot into a rope will bring the force load level down to a point that still far exceeds what you need to catch a good whip. I'm not sure about dyneema in other forms, but since it doesn't have the kernmantle construction that most ropes and cordelette used for climbing and "life support" typically have, I imagine that may have something to do with the handful of dramatic results you've seen. The only use for dyneema cord as opposed to slings in the Petzl facility that I noticed was for non life supporting uses (e.g. the foot cord used in conjunction with an ascender for jugging up a rope). IME the only material I've seen recommended by the manufacturer for use in a life supporting context with knots in it is kernmantle construction rope. Cyclic fatigue is a real issue. If you are using the same knot or tying one in the same spot over and over, you will significantly weaken that particular spot in a sling (or a rope for that matter), so this is certainly something to watch out for. |

|

|

Jessica Colley wrote: Basket hitch would probably work OK on my big WC tech friends -- I think the sling holes are 5/16"? So there's enough room to pass a bight of skinny (6-7mm) sling through, for a basket. But I was kind torn about the possibility of dropping the sling and/or the cam while tryna unrack it. But yeah, it sounds like your basket hitch idea is probably the strongest non-sewing approach I could get on those cams. Sadly, I could not figure out a way to basket hitch these damn Big Bros. The holes are just too small to pass more than one strand of anything bigger than 3-4mm, max. If you have any groovy ideas to make that work, I'm all ears.

I hadn't really considered the issue of cyclic loading at the knots, going forward. But I have noticed some funny spots under the knots of slings I've removed from secondhand pieces. Might be worth making a note to replace my tied slings a little more often than sewn. |

|

|

Jessica Colley wrote: Slings made from flat dyneema are very commonly used as anchor rigging in a life supporting context, often with master point and/or limiter knots. This usage is even shown in the Petzl documentation for their St'anneau slings: Quad anchors made from larger loops (e.g. 240cm) of dyneema are also quite common, and by their nature are super good enough even with knots in them. Petzl also shows this on their page with anchor information: https://www.petzl.com/US/en/Sport/Installing-an-equalized-belay-station?ActivityName=Multi-pitch-climbing AMGA/IFMGA guide demoing anchor with tied dyneema slings: https://youtu.be/2mSZ5ROlPoY?si=jm5okoNa6dh51ViR |

|

|

Kyle Tarry wrote: Thanks Kyle for helping to clarify with manufacturer's recommendations, as I was getting a little confused by certain individual comments above, as we frequently use sewn dyneema slings at anchors, some with master points and/or limiter knots. |

|

|

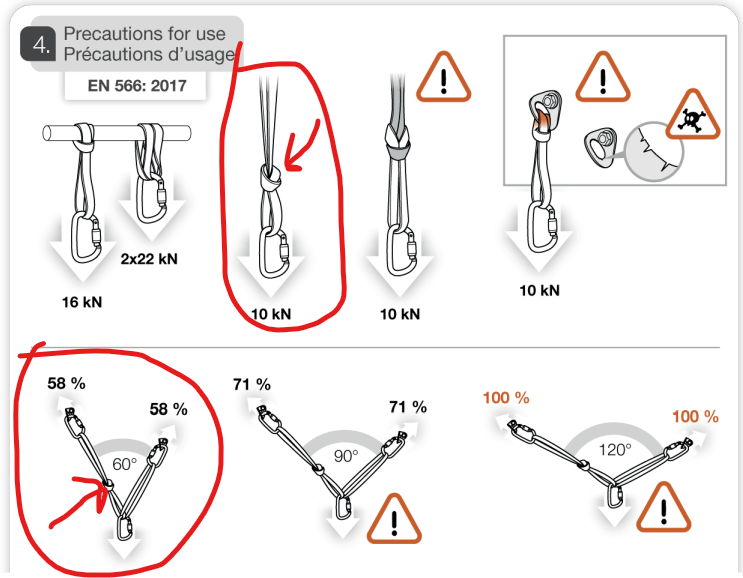

Kyle Tarry wrote: The point was not to never tie knots in slings in a life supporting context, it was that they recommended basket hitching over girth hitching or knotting whenever possible, which is exactly what this diagram shows. It shows 2x the kN load with a basket hitch, around a 30% reduction in load capacity with a girth hitch around an edge-less connection point, and more than a 50% reduction in capacity with a knot of any kind or a hitch over a sharp edge like a bolt hanger. The goal of this diagram is that you are aware of the way different uses of the sling reduce its load capacity and make informed decisions accordingly. The second half of the diagram shows putting a knot in a sling, which would reduce the load limit, but demonstrates ensuring not to make your anchor angle too obtuse which causes further issues. I think the overall point is to be aware of the reduction in load limit, especially paying attention to using a sling that has a high enough initial load that reducing it would not cause it to drop beneath a reasonable amount of kN. The current CWA standard for an attended belay anchor is the lesser of 13.3kN or twice the anticipated load (which depends on the size of the climber and the size of their fall). It’s also important to note that all this info is for sewn slings, not hand tied loops made of sling like the OP is talking about using for their pro, so I imagine that leads to a whole other set of factors entirely. |

|

|

In fact, I think the little warning sign is for the two demonstrations of a master point/overhand knot and what looks like joining two slings together reducing the sling to 10kN and thus warning you against it being used solo. The lower part of the diagram actually shows using TWO slings with a limiting knot in one, so if the knotted sling (rated 10kN) blew, you would have a totally separate backup (rated 22kN) and the load is distributed between the two. |

|

|

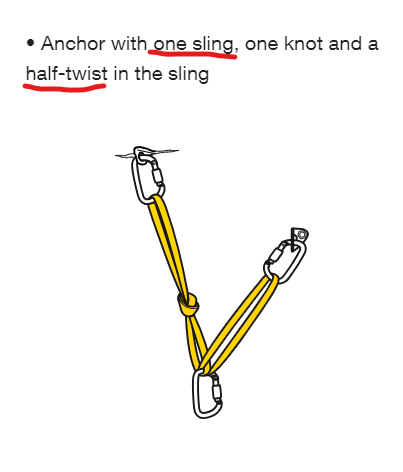

Jessica Colley wrote: Maybe we're talking about two different things. A basket hitch is absolutely stronger, and in industrial applications, it makes a lot of sense. But for a climbing application where you're building an anchor, you need the knot specifically to make the system redundant and non-extending, a basket doesn't do that. (Above I was just pointing out that manufacturers do describe and endorse knotted slings in life-critical applications, it's just situational.)

It's a single sling with a limiting knot on one side and a half-twist at the carabiner (colloquially known as a "sliding-x"). See the other link I posted: https://www.petzl.com/US/en/Sport/Installing-an-equalized-belay-station?ActivityName=Multi-pitch-climbing |

|

|

Ryan Lynch wrote: also consider inspecting and replacing your tech cord (powercord) more often than standard nylon accessory cord. |

|

|

I think this discussion is focusing on the wrong thing. There are lots of accidents in climbing, but are there any documented accident from a sling failure due to a knot? |

|

|

Several water knots have come undone in nylon webbing and precipitated tragic events. The cyclic loading failure mode is well documented. That there are no accidents with knots tied in high tenacity fiber slings might be due in part to the fact that climbing manufacturers/retailers do not sell bulk sling material--because it cannot be usefully knotted. Again, the failure mode is well documented; the fibers are slippery enough that the end of the cord just slides through the knot. And yes, if you want to worry about climbing risk, do a partner check before climbing, pay attention when rappelling, belay correctly, self arrest correctly. That said, it's not a bad thing if climbers are aware of the limitations of knotted, high-tenacity slings. |

|

|

dave custer wrote:

In my limited capacity to to perform pull tests at home (@400kg dead load) I've tried some common knots in the 6mm tubular Beal webbing that I've been using on my BBs. On well-dressed, pre-snugged knots, I didn't find any slip for these knots:

But the Flemish (figure 8) bend and double fisherman may have slipped a bit. I wouldn't extrapolate any of this to flat dyneema webbing, wider dyneema webbing, or even higher pull forces -- there's just too much at stake. Somebody with better equipment needs to properly pull test theae knots on various dyneema types & configurations. It would be really, really nice to have a known, tested, go-to knot/bend that really does hold fast in any type of dyneema webbing. Also, I haven't seen much testing of knots in dyneema braid rope (amsteel) beyond our basic overhand/figure 8 loops. I'm really curious if the bends with more interior surface area (stevedore & figure 10) perform any better than the figure-8's mediocre showing ( m.youtube.com/watch?v=MdA9m…). A bend that can reliably join amsteel (no slip & >50% strength) could open up some new possibilities for how to use that stuff in climbing. |

|

|

dave custer wrote: Would you suggest that climbers not use any type of anchor that includes a knotted dyneema sling*, as all of those depend on the knot to provide redundancy and/or extension reduction in the case of partial anchor failure? *Such as pre-equalized master point, limiter knots, quads, SWAMP, girth hitch, and clove hitch anchors |

|

|

Kyle Tarry wrote: Lots of climbers use those all the time, but I'd bet they almost all only see the body weight of the two climbers, and haven't been subjected to anything resembling a heavy load (FF2, etc). I'd prefer my anchors to be able to withstand the worst case scenario (otherwise I'd be happy with 3mm cord, 2 micronuts, and a DMM XSRE keychain 'biner for an anchor), so I personally don't like using skinny dyneema slings for an anchor. Sure, Petzl's tests show that knots in this material are still in the "super good enough" range, but those are likely using brand new, off the shelf slings. We know that the strength of these slings can diminish pretty radically with some mystery combination of age/exposure/abrasion/cyclic loading. Since most of us aren't replacing these slings after every outing, in practice they're likely not full strength anymore, and adding the reduction in strength of knots puts them into the "not trustworthy for critical anchors" category for me. Luckily, a nylon cord, sling, or one of those thicker dyneema mixes (like available from Edelrid, Mammut, etc) per anchor isn't that much more overall weight, and is much more robust for this purpose. Anyway, that's my thoughts on the subject, but without thorough testing, it's all admittedly based on conjecture. |

|

|

Brandon R wrote: I think there's two subtly different things being discussed here:

Dave Custer's post that I replied to is about item #1. An assertion that these materials will not hold a knot means that scenarios where we're depending on those knots could be really problematic. I think you're talking about item #2? If so, I think your concern is justified for sure. I also think it's useful to be specific about the scenario we're thinking about. For example, an equalized tied masterpoint type anchor using a long dyneema sling and 3 pieces of gear has a masterpoint with 3 loops, so even with some serious strength reduction it's still quite strong. However, perhaps the strength of the individual legs could be low enough to warrant concern (e.g. the HN2 tests showing 8 kN failure of a single dyneema loop with a knot). Definitely thought provoking. (Edited a bit because I was rambling) |

|

|

Kyle Tarry wrote: Ooops, you're right, I'm off topic. (I remember seeing one that broke at 6kN... a BD 120cm dyneema that looked identical in condition to one on my rack!) (And I agree, I wouldn't be too concerned with a 3 piece anchor and a BFK masterpoint configuration) |

|

|

Brandon R wrote: Nah I think it's relevant! Just trying to keep the different limitations straight in my head. I'm totally on board, 6 kN is a bit scary if you're depending on each of the pieces in your anchor to be a nice strong 10+ kN placement. |

Continue with onX Maps

Continue with onX Maps Sign in with Facebook

Sign in with Facebook