Tying slings on Big Bros (and cams too, I guess)

|

|

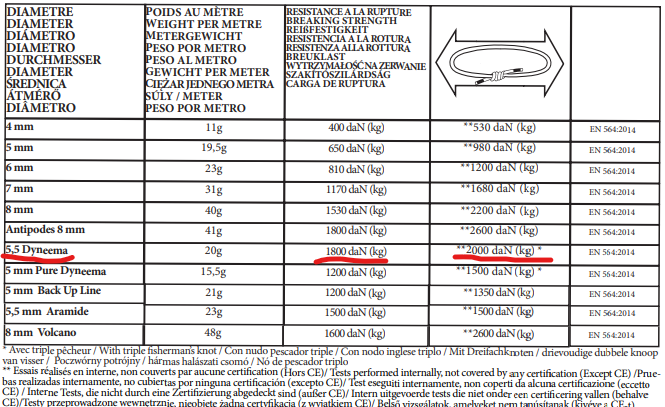

"Sling the BigBro with 75cm (30”) of 6 mm Tech Cord. The knot should be tied on the side of (from Trango's instruction manual: https://cdn.shopify.com/s/files/1/0282/7557/2841/files/Big_Bro_Instructions_Includes_5.pdf?v=1614361901) Doesn't specify any particular strength, but I've seen some old forum posts that give me the impression that an older manual may have specified 13kN -- but no idea if that means with knots, or without. Beal's 5.5mm tech cords both (Dyneema & Aramid) seem to have 18kN breaking strength, but I can't find a reference on their own website. Maxim says 21kN for their 5mm tech cord. New England says 14kN @ 5mm (T100)... Kind of interesting how big of a spread there is between the high & low ratings -- but maybe I don't understand rope ratings well enough. And if you're the type to care about these things, none of the tech cords seem to be particularly rated for PPE use. The past few years, I've used 6mm dyneema webbing (Beal's skinniest runner @22kN rated) tied with two water knots, back-to-back. (FWIW, I can hear you already with your knots-in-dyneema talk. Feel free to lecture me, if you need to get it out of your system -- no need to limit yourself on my account :-) That said... I have been considering switching from away from the two water knots, in favor of something that preserves more of the cord strength, and doesn't come undone. Normally I wouldn't bother with webbing -- but this 6mm stuff is so skinny, it's practically round. So most regular rope knots seem to dress up OK, and can be visually verified. Triple fisherman works fine -- I wasn't able to budge a properly snugged triple fisherman with >400kg dead load. Unfortunately, it doesn't seem to be much more efficient than water knots. For higher efficiency, I've mulled a couple of candidates: • Flemish bend, AKA, figure 8 bend More efficient than water or fisherman knots, but seems to slip a bit in this webbing @400kg. I don't have the equipment for a proper pull test, so I don't know how that story ends -- but it makes me worry. Jams up tight under load, so I trust it not to spontaneously untie itself. • Zeppelin bend At least as efficient as the Flemish, and did not slip at @400kg. Doesn't jam up nearly as tight as the Flemish, so I don't know if I trust it to stay secure over time. Downside is that climbers don't learn the Zep, so it's black magic to barbarian minds... On the other hand, consider that Zeppelin fucking rules, man. • Stevedore bend, AKA, figure 9 bend Oddball enough that it's not even properly googleable -- but the knot has been studied & tested. It's basically just stronger and less jammy than the Flemish/fig-8 that it's based on, which makes it pretty easy to understand for climbers who already knows the parent knot. Did not slip @400kg, but did jam up enough to feel secure for long-term racking duty. • Figure 10 bend An extra half-turn on the stevedore/fig-9 makes it even stronger and less jammy. It's been tested, but doesn't get much press. Did not detect any slip @400kg, but it also may not jam enough for a racking knot. Now... If you've read this far, you might be the kind of nerd who has also realized that none of this is particular to the Big Bro -- except in that the BB sling holes are *too narrow* to admit wider webbing like would sling a cam. And while it's absolutely possible to sew round cord to preserve it's strength (e.g., Beal Jammy) those sewing techniques aren't nearly as widespread. So we mostly seem to stick to the sewn webbing approach on cams... But if you're the sort of brokeass who ties their cam slings with water knots instead of paying for a proper sewn job, you might have had some thoughts on this topic, yourself. And if you did bother to read this far, I only have one genuine question: Why does Trango specifically instruct us to tie the sling knot on the side opposite the trigger button? Do you think it really matters? If so, why? |

|

|

Beal’s dyneema 5.5mm break strength is 18 kN, the kevlar core is 15 kN. The EStar bend is very secure and holds up to half the break strength, about the best that can be achieved with knotted dyneema. |

|

|

A bigger length of starting cord may be a more pressing question than the cord used. The small loop here, IS 30". You could always try to use hollow 12 strand dyneema (ie. Amsteel) and brummel splice one loop to capture the big bro and the other as a clip loop... you get great "efficiency" as splices preserve strength better than knots, but poor abrasion resistance. |

|

|

Desert Rock Sports wrote: Re: Tech cord... Everything I've ever seen referenced by that name has been either dyneema or aramid core. Outside of climbing, everyone seems to agree that knotting ANY kind of dyneema or Aramid textile will result in equally terrible performance -- regardless of whether that dyneema/aramid is shaped as a sling, braided rope, or sheathed in woven poly or nylon. If we take the rated strengths of those various tech cords, and derate them by 60%, we get some scary low values, in particular: • ~8kN (Beal) • ~6kN (New England) neither of which seems even remotely strong enough for a device which claims a rating of ~12kN IIRC. Basically what I'm observing here is that "whatever tech cord" might be a lot weaker than a climber expects. Doesn't that bother you, at all? |

|

|

Ryan Lynch wrote: If you want maximum strength, one of the tech cords rated for ~20 kN should get well over 10 kN, even with 60% (or greater) derating. The BD #7 is rated to 8 kN and the #8 is rated to 5 kN, so concerns about 8 kN being in sufficient for a Big Bro might not be well grounded. UIAA minimum test strength for camming devices is only 5 kN. Also, to be fair to Trango, they specifically say to use 6mm tech cord. The weaker cords in your original post are 5mm, so not following manufacturer's instructions. 1 mm might not seem like a lot but it's like 30% less area/material at this size, so it make sense that the strength would be lower (although probably still fine).

The specs are in the "Notice" (e.g. instructions) PDF. Kinda buried in there but here's a screenshot (18 kN single strand, 20 kN in a triple fisherman loop):

What do you mean by "PPE use?" There are lots of different standardizing bodies and standards out there, but generally PPE refers to professional/industrial use. If that's the context, lots of climbing gear (such as carabiners) also isn't rated/certified. Here's some info about some of the different industrial carabiner standards and how they differ: https://dmmprofessional.com/Knowledge/December-2012/ANSI-standards-for-carabiners |

|

|

if placed properly the #8 Camalot it can hold like any other cam (>10kN). if placed really bad it’ll break at like 3kN. there’s a BD QC test, look it up! if my numbers are wrong, lmk, i didn’t double check :) |

|

|

I wonder if you could just throw a sling over a placed big bro (treating it just like a chock stone). |

|

|

Kyle Tarry wrote: Interesting... BBs are all rated @12kN, and my big WC tech friends (which also need re-slinging, and have tiny sling holes) are rated @14kN. I had no idea BD's big gear was rated that low... If it's possible to sling them to at least their actual rating, I'd like to try. Good catch on the 5mm vs 6mm cord, on Trango's instructions... I walked right past that and didn't even notice. Edelrid & Sterling both do have 6mm dyneema/aramid rated ~21-22kN. But the ratings you dug out for Beal's cord (thank you! Good eyes) got me even more confusing... My first thought was that they appear to be claiming that the tied loop in triple fisherman is *STRONGER* than the cord itself? I don't think that's physically possible with any kind of textile. So I'm guessing that the cord is actually capable of well more than 20kN a single strand -- but they don't bother rating it beyond what the standards require? |

|

|

Ryan Lynch wrote: The standardized rated strength (UIAA-102 / EN564) is for a single strand with no knots pulled over a large radius drum. The loop strength is the strength of TWO strands, minus the knot reduction. I think you're missing the fact that a loop has 2 strands in all your calculations above. For example, you suggest that the NE ropes cord (rated at 14 kN) would be only 6 kN in a tied loop, but I calculate 14x2x0.4=11kN. I still would suggest that 8 kN is probably plenty strong for a Big Bro, but any of these options is going to likely be stronger than that.

The UIAA/EN standards for 6mm accessory cord requires a minimum strength of 7.2 kN. There is no separate standard for alternative materials (such as dyneema, etc.) that I am aware of. I would expect that the manufacturer's rated strength is the typical conservative rating based on lab data with normal statistical derating factors. |

|

|

Kyle Tarry wrote:

Nope, I just checked -- looks like you're right about this... This also means that the pull tests that HowNot2 did aren't really representative of the strength of a tied sling on a cam or BB, because of where they knotted them. |

|

|

Ryan Lynch wrote: Can you link to the specific test? They've done so much over the years, I don't want to comment in error because I'm thinking of the wrong thing. Generally, I would say that tests can often apply to other scenarios that don't look the same. For example, the strength of a knot in some cord is applicable whether that is a single strand or tied in a loop (you just get differed multiples of the tested strength). |

|

|

@Kyle Tarry, the two videos I mentioned earlier are here: The first one covers a lot of topics, but if you scrub to 8:30 they pull test (#791) a dyneema sling with an overhand knot across both strands, which breaks ~40%. Their whole data table is shown near the end, in the last 1-2 minutes of the video. The second one is focused on knots in braided amsteel. I wish they'd do some Big Bro pull tests. Maybe it'll happen when more than 0.0001% of the climbing population starts using them? |

|

|

I used Bluewater 5.5mm titan cord to sling my Big Bro. Fits through the holes and is plenty strong for my comfort level. |

|

|

Ryan Lynch wrote: These both just kinda show the same numbers we've been discussing in the whole thread. An 8mm dyneema sling probably has a single strand strength of approx. 10 kN, so it's ~20 kN sewn in a loop, and it loses ~50-60% of its strength with a knot so it ends up down around 8-9 kN in a knotted loop. The amsteel tests show the same strength reduction (roughly). Note that regular 6mm accessory cord (7-8 kN MBS) holds 10-12 kN when tied in a loop, so even that is probably plenty for a Big Bro or an old slung hex. The tech cord just gives you a bit of additional margin (not as much as you'd think from MBS numbers though, since it loses more strength in a knot). |

|

|

Kyle, thank you SO much for walking through all of that. This whole thing makes so much more sense, now. |

|

|

Ryan Lynch wrote: Now that you understand that much, understand this too: |

|

|

Desert Rock Sports wrote: This is fan freakin tastic... Thank you! What a great white paper! TBH I wish the HN2 guys did this kinda report on their own results -- but they seem keen on sticking to their "Entertainment, not Science" approach. Man, if I only had a few racks to drop on a pull table and crane dynamometer... Naw, who am I kidding -- I'd just spend it all on gear & gas |

Continue with onX Maps

Continue with onX Maps Sign in with Facebook

Sign in with Facebook