What size hanger bolts do you run into?

|

|

With the winter that we have had in our area, I am finding more and more loose hangers out there. I'm looking to build a tool that will cover 99.9% of what we run into. In my area it's mostly 3/8 in and 1/2-in bolts (9/16 in and 3/4 in nuts on them respectively). I will obviously include 9/16" and 3/4" but what other wrench sizes do you see? 8mm bolts I believe require a 10mm wrench but need to confirm that. What size wrench do the majority of the 10mm and 12mm bolts require? What else is everyone seeing? I know there are some obscurities out there. Thanks |

|

|

The tool you’re envisioning was invented a long time ago. It’s called a spanner wrench and can be purchased at any hardware store in the world. |

|

|

3/8" Power Bolts have a 1/2" head and that's the 2nd most useful size after 9/16" |

|

|

I run into sleeve bolts that have a funky size 1/2? A small crescent wrench is about as good as it gets for tightening any and all bolts. |

|

|

Good luck, watch your knuckles. |

|

|

Why cover 99.9 when you can cover 100? Crescent wrench. Unless you're trying to make money off it. In which case just write "Alex Honnold" on the side of a crescent wrench. |

|

|

Devin Hanes wrote: I've been curious about the Al spanners - with frequent use the steel nuts will chew up the aluminum but for the occasional tightening it should work. Though the times when I'm climbing a bolted route where I care about pack weight is rare, usually I just keep a 6" adjustable steel wrench on my rack of draws. |

|

|

|

|

|

https://www.knipex.com/en-us/products/pipe-wrenches-and-water-pump-pliers/pliers-wrenches |

|

|

Devin Hanes wrote: I don’t think you can get much torque with this when it’s close against the rock and you can’t get your hands around it. PS to the OP, all the bolts I’ve run into were crescent wrench sized. |

|

|

Lobtex UM30XD. This lightweight thin 8" steel wrench at 170 g has worked well for me. An edelrid 19g fits the end hole really well. https://www.amazon.com/dp/B004OCS9XK?ref=ppx_yo2ov_dt_b_product_details&th=1 8" aluminum wrenches are 40 g lighter but have much thicker jaws than the lobtex. 8" titanium wrenches are also around 40 g lighter than the lobtex, thicker, and 6x the price. https://countycomm.com/products/8-inch-titanium-adjustable-wrench-nsn-pending |

|

|

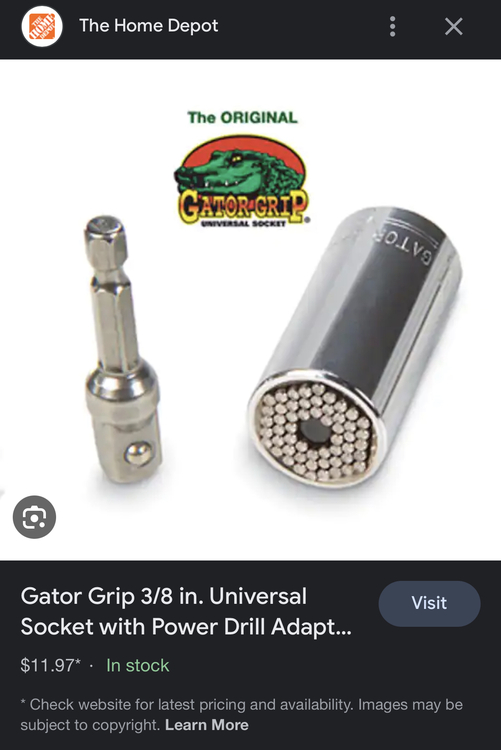

Boomer Climber wrote: These are awful. The pins break easily |

|

|

Metolius used to make a nut tool with several sizes of bolt heads built in. Not sure if they still make them. |

|

|

Chris Douglas wrote: Are you planning on this wrench being able to torque to manufacture specs as well as adjustable? Edit: if these bolts had been properly torqued would the hangers have come loose? |

|

|

Thanks for all the responses so far. It won't allow me to multi-quote everybody but here it goes. Those universal pinned sockets bend the first or second time you use them so those are a no-go for me... I wish they worked well and consistently. I've been using a crescent but as soon as you get angle on them due to rock etc you start getting slippage and I don't want to round off nuts nor beat my knuckles up too bad. The metolius tool works great as long as you have a nice flat area and the hanger is open enough to allow enough swing to get to the next position (this weekend I got into that position and the metolius would not work where I was at). The AN aluminum crescent style wrenches are great for aluminum but steel or stainless steel even in AN sizing chew them up pretty badly. They may work a little while but Even when I use them in automotive (I'm a mechanic on the side and work with AN a lot) on the proper sizes the stainless destroys them and typically they are actually built with larger tolerances than a good standard crescent. I am not looking to torque to manufacturer specification technically. I'm more looking to build a really lightweight tool that well help you in a pinch and will be worth packing way into the backcountry. I didn't even think to use my knipex pliers... I'm going to test those this weekend. So far those are the best "universal" pliers I've used and I have a set in my box already. |

|

|

Chris Douglas wrote: The Knipex Pliers wrench are excellent. Not all adjustable (AKA Crescent) wrenches are the same. Check it out: 9:00 in for the goods |

|

|

Devin Hanes wrote: Good to know, I have always wondered about this as an issue. Would a nyloc nut solve this issue(?) |

|

|

Hot and cold swings make everything expand and contract, plus loading and unloading etc. Wedge bolts will loosen over time and use. In some of our areas, water and ice getting in the holes I assume also works them loose. (Not a pro, just opinion). I don't think Nyloc would solve the issue permanently, especially with UV exposure. The nylon usually deteriorates after a few years in the sun. I'm not sure what causes them to loosen in every situation but I feel better on a tight bolt for sure hahah! |

|

|

Chris Douglas wrote: It's a hassle but rock dissolves in water, the more pressure on the bolt the faster this occurs. With wedge bolts and sleeve bolts the contact point is extremely small and the actual pressure very high so erosion can be suprisingly fast. Freeze push-out is a weĺl known problem, the Alpine associations recommend the lifespan of mechanical bolts in freeze/thaw environments to be ten years and we've certainly seen bolts completely pushed out from the rock in those sort of time periods. The rock also erodes from under the hanger, at one of the areas where I was brought up the cliff has eroded back nearly an inch since the resin anchors were installed around twenty five years ago. Nylocs are a mistake and often prevent re-tightening! |

|

|

https://www.youtube.com/watch?v=WbLS3rGtKDM |

|

|

Jim Titt wrote:

At what point do you replace these resin anchors? |

Continue with onX Maps

Continue with onX Maps Sign in with Facebook

Sign in with Facebook