Core drilling tools for bolt replacement

|

|

Core drilling is another option that might work better than spinning and pulling. In the past I have used a diamond core bit only on Mammut ring bolts or self-drives that already have a 1/2" hole. The process was complicated by the need for a 3/4" OD, 5/8" ID stainless spacer to support the lip of the hole for the glue-in replacement bolt. I didn't think there was a bit that would work for 3/8" bolts with a thin wall and a long enough reach, but I recently found one. I emailed several factories until I found K M Glass Tools Store. They sell a water adapter for $16 and the bits they make have a thin wall and about a 3.25" length of cut. The bits are cheap at ~$14 each, and they claim that the bits can drill thousands of holes. I have removed 4 test bolts using a couple of different size bits and the results are encouraging. It takes ~3 minutes to core drill around a wedge bolt in granite and I used about 1 cup of water. The water supply line is some automotive vacuum tubing with a 5/16" ID. In the past I have used a Dromedary bag hung from a Prusik to control the flow, but this squeeze bottle works ok. A regular drill will work, which can expand the resources for large volunteer events where rock drills are in short supply. I bought three sizes: 14mm, 13mm, 12mm (OD)

I bought the Morse taper for the sake of the longest cutting length, but there are some drawbacks. In order to remove the bit from the adapter I had to use a vise and a hammer which would be difficult while hanging on a rope. This is what you will search for to find the tools. They arrived two weeks after I ordered them. K M Glass Tools Store on Aliexpress

|

|

|

This is awesome, thanks for sharing. Would pair well with this: Heavy Duty Professional 1/2-20UNF 13mm Keyless Drill Chuck with SDS Adaptor Hardware Tool a.co/d/fNU2WtF |

|

|

|

|

|

great info |

|

|

bmdhacks wrote: This says converts “impact” but they must mean converts sds rotor hammer? |

|

|

The seems rad, I feel like spinning generally takes longer than 3 mins, I guess the main downside would be the water usage, sounds like you would need 3+ liters of water for longer routes. Are there any concerns with the very smooth hole providing insufficient interface with glueins? It seems it could be very useful for the powers lokbolts with the segmented sleeve. I would guess that you would need the 13mm for those as the sleeve is probably bigger than the threads on a 3/8" stud. Also would be helpful for old 3/8 5pc, we generally unscrew the bolt and then just drill out the sleeve with a rebar bit, but frequently the head of the bolt shears off, which leaves you pretty screwed. |

|

|

Battery power will be more of a limiting factor for this technique than it is with spin/pull. The water usage per bolt is actually less than I had expected. I think that there is a failure mode of the bit if you overheat it where the diamond cutter will separate from the shaft and break off in the hole- that's going to be a chop and patch moment. A hybrid technique might work where you core drill the first 1.5" and then pull really hard on the wedge- if it slips, great; If it breaks, go back to core drilling. These bits should work for both 3/8" sleeve bolts and split shaft/compression bolts. It might work out that you can get needle-nosed pliers on the sleeve after coring ~3/4" deep. The cone will still be undisturbed, so you will have the option of using a draw stud or funking it out with the original bolt. I've seen 10mm stainless wedges that needed to be replaced because they were over-tightened and the threads stretched. The stainless steel galls easily and often they won't spin. Some break when you try to remove the nut. The 14mm core bit would work for those nicely. The smooth wall is an issue- using a longer replacement bolt or up-sizing the hole in order to rough it up are good options. If the 13mm bit creates a hole that would work for either mechanical or glue-in bolts, we would have the best of both worlds. As it is, the 12mm still looks pretty good since boring it out to 1/2" after the removal doesn't waste very much battery power. |

|

|

Great find! And thanks for sharing your results. I spent over an hour on Taobao (China's version of Amazon) trying to find other manufacturers that readily carried the extra long bits, and only KM Glass Tools seems to be the one that has them. Other factories bits only went up to a 60mm drill depth. I've got an order in already with KM to try it out. For those in Asia that know how to order off Taobao, here are the links: 【淘宝】https://m.tb.cn/h.UJGsSsn?tk=sOFqdQ2hxI9 CZ0001 「大理石锥柄加长钻头,金刚石烧结钻头,石材钻头」 A set of 12mm to 14mm, plus the water chuck cost me 970 TWD (about $31.75 USD) |

|

|

Greg, can you expand on the process for removing the core/bolt/debris from the bit after the hole is drilled? Any tools needed? |

|

|

bmdhacks wrote: So far I have been able to remove the bolt with my fingers once I drill down to the expansion collar. One test bolt slipped deeper into the hole so that the tip of the bolt was almost below the surface. That made me think of a tool that I plan to make: a skinny coupling nut made from 1/2" OD steel tubing with a few 3/8-16 tapped threads inside. It will fit in the cored hole and screw onto the bolt. The opposite end could have tapped threads if you want to connect it to a draw stud, but that might not be necessary. Making it into a t-handle wrench by adding a thinner steel cross dowel might be sufficient. Hemostats might also work in that small gap between bolt and rock wall. If the bolt breaks off deeper in the hole, you'll be drilling deeper with the core bit until the bolt is completely loose. Eventually it should rattle around inside the bit and get drawn out as you remove the bit from the hole (that's what has happened with the larger bolts I have core drilled). |

|

|

This is great Greg! The water attachment especially seems more effective then just a squirt bottle alone. Have you tried this on any 1/4" split shafts yet? I've mainly seen this method used to remove the split shafts after breaking the head off / snapping the stud in the hole. Im curious if you might need a smaller diameter for that to actually loosen the stud from the rock. Thanks for everything you've posted. Can't even explain how much these posts have helped in getting my kit together... |

|

|

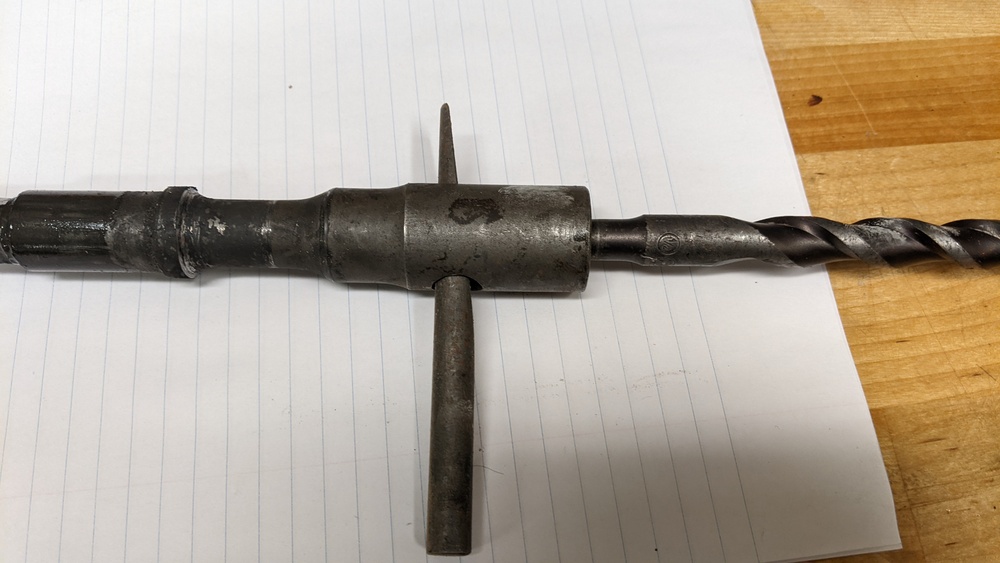

Gregger, great find. I tried core drills several years ago but had no luck. The biggest problem was keeping the bit aligned with the bolt. When out of alignment, the core drill would go right through the bolt diagonally making a mess of the hole. It looks like these bits might be self aligning to the bolt. To get the bit out of the Morse taper, would it be possible to drill a cross hole through the Morse holder at the end of the bit and use a tapered drift pin to drive it out? The drift pin should be somewhat hard but it could be made by grinding down a grade 5 or 8 bolt if you keep it cool. Before SDS bits were common, I used to make drilling holders for A-taper bits and always used a drift pin to get the bits out of the holder. If the Morse holder is too hard to drill through, buy a carbide drill. Photos are of a 3/8" round A_taper removal drift pin. |

|

|

Dan - I had emailed the supplier about tools to remove the bits, and they just said I should be able to find an appropriate tool locally. Although a drift key is the standard way, that's impossible with this swivel water adapter since the water would leak out of any hole you drill. As it is, I hold the bit with a soft jaw vise and tap a few taps with a punch on the business end rim of the adapter and it falls off the bit. With the 12mm version, even if you get off the axis of the bolt there is enough wiggle room to end up with a clean 1/2" hole after reaming with a rock bit. Tyler - haven't tried any 1/4" bolts yet, but you are probably correct that you would want a smaller diameter. They sell them in these lengths down to 8mm OD which should have a ~6mm ID. |

|

|

Greg i made a wedge from an old piton for my Rawl #20 taper drill holder. Built in tether connection too. To spin or core drill seems like a personal preference thing. A gluing rig weighs less than the water required to do more than a few bolts. If there is a water source at the crag it might be a very good choice. Be careful not to let the drill hang from bit while it is in the hole. Real easy to break the tip off the bit. Ask me how I know. For me, if I cant get the wedge to turn in the hole(or the hole is filled with glue) i red neck core drill. A few 3/16 bits adds very little weight to the kit. A final thing to consider, if the route is steep you will get wet with the core drill method! |

|

|

Greg, For the water supply, were you just letting it flow via gravity without any regulation from the drom? Also here are links https://www.aliexpress.us/item/2251832594908497.html https://www.aliexpress.us/item/2255800785143721.html |

|

|

The issue with getting the bit out is that there is not any ridge or bump to prise against. Drift keys and wedges that look like tuning forks are readily available for all sorts of drill bits, but all of these bits below the diameter of the Morse taper hole have nothing but the shaft to pull on. (Hey!: Stop snickering!) I've only used a core drill alone on a rope a couple of times- usually I can wrangle a willing co-conspirator. If the rope runs above you it works well to just let the water trickle, but you will use more water that way than if you control it as you drill. I'll probably use a siphon primer bulb like this so that the flow of water can be easily managed from a bottle with an air vent (or a Dromedary bag below me). I hadn't included direct links because I had assumed that they would be auto-deleted as spam. |

|

|

Got this in the mail! Paired it with the cheapest $11 amazon hydration bladder I could find. I'll report back after I use it, but my initial analysis is that the diamond coating on the drill bit is extremely fine grained, like 400 grit. I'm skeptical that it won't take forever to actually drill through rock and steel with such a fine grain, but we'll see. The Alibaba photos of the bits seem to indicate a more granular diamond coating than what I've got. I'm anticipating the hole to be super smooth, which would make me uneasy using it without wallowing it out with a roto-hammer bit. Still, I'm starting in on rebolting lines on a crag that's been long abandoned, and most of the bolts just shear off when you spin or pull them, so this will be really useful. Note the flaking rust inside the hole, which has expanded to the point of fusing the stud with the rock independently of the wedge. This bolt just mushroomed when I tried to hammer it in to disengage, and a tug on the yabr snapped it with little effort. |

|

|

We removed 15 bolts with one battery and about ~2L of water (we spilled a bunch, so I don't have an exact amount) We used the 14mm OD bit since we knew we would use twisted leg glue-ins and almost all of the bolts were rusty 3/8" 5-piece which can take a lot of time to remove using a tap or drilling thru them. Less than 2 minutes per bolt is not bad. |

|

|

Very intrigued! I ordered the adapter and bits. Can't wait to try this out! |

|

|

Gregger Man wrote: Did you ream the holes out to 5/8 after? Or just use them as is? |

|

|

Gregger Man wrote: If anyone tries a smaller version on 1/4", let us know how it goes! I'd probably plan on a larger internal diameter than 1/4" or 6mm - most split-shaft 1/4" aren't fully compressed, and in some rock it's common to find them barely compressed at all (grainy granite, medium quality sandstone, etc). When not compressed, a split shaft is about 5/16" or 8mm wide at the split. Greg, any thoughts about going after 5/16" buttonheads with these? Thinking of just trying the 12mm bit and drilling straight through the head of the bolt, the hanger (only if it doesn't fall off once you get through the head), and continuing into the rock? Or would it glance off the rounded head as you're trying to start? |

Continue with onX Maps

Continue with onX Maps Sign in with Facebook

Sign in with Facebook