Good Friday the 13th, the birth of a new Beak

|

|

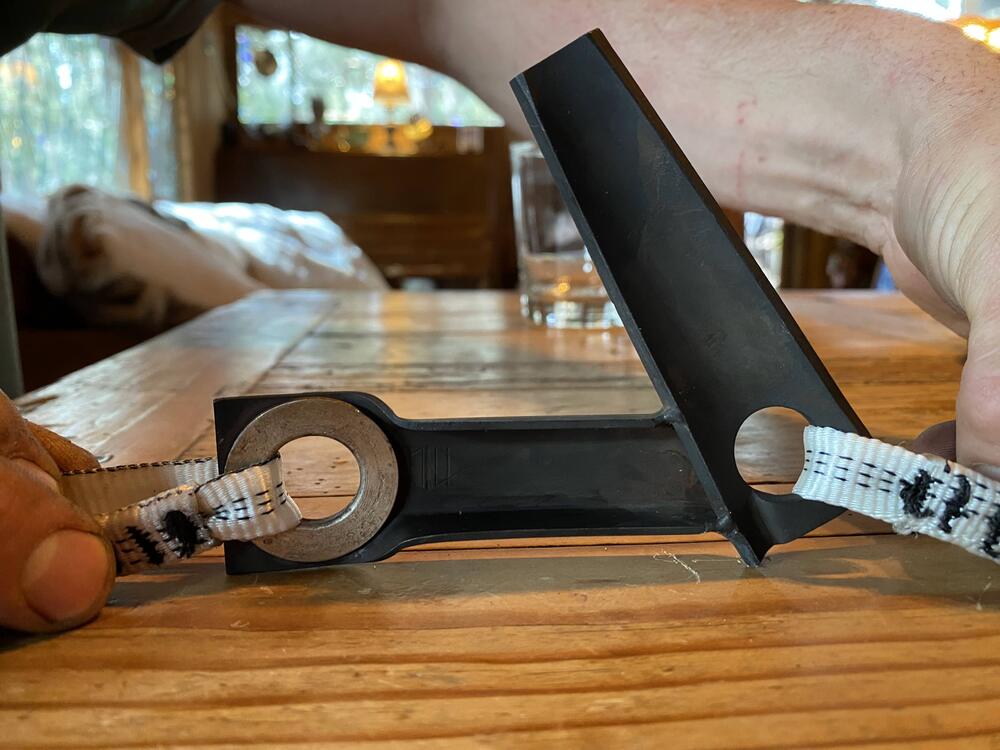

Expando Slayer, The new beak on the wall. This 4130 Chromoly beak has a concave blade with a range of .17 - .315 inches. A unique channel stem allows weight to be reduced to 86 grams (including 2 slings) while still maintaining a geometrically robust construction. The blade is connected to the stem via a ER4130 filled tig weld, followed by heat treatments to produce a joint the same strength as the parent metal. The aluminum bushing on the stem creates a wider bend radius for the sewn sling or carabiner. Both blade and stem holes have been designed to reduce sling trap and abrasion. I decided to make these available because I became unable to regularly obtain SMC shallow angles, which is the only other piton I carry other than beaks. The SMC (or standard angle piton filed length wise) has always been a great tool for loose, expanding or otherwise variable conditions (think cam hooks in sandstone). This beak takes it to another level, giving you the flexible spring bite of the shallow angle and the hooking nature of the beak. I hope you enjoy it. Any questions, modifications or critiques are welcomed. In the coming days I will make another post that will be a fun contest with the prize being a rack of 3 Expando Slayers. |

|

|

Wow huge congrats man looks good! Friday the 13th luckiest day for some sketching-out aid climber haha Woot!E Yosemitebigwall.com |

|

|

<3 |

|

|

Yup! These are what pitons would have evolved into had pitons continued to evolve. Good work! |

|

|

Damn |

|

|

Badass!!! I welded a couple BD beaks together in a triangle/ wedge kind of shape years ago but never actually racked or placed it!! Good work man, I love it. |

|

|

Superb idea! |

|

|

Skot Richardswrote: Interesting, was the goal to simulate a beak stack but permanent? Am I visualizing the weld orientation correctly? |

|

|

Cool tool, the weld would scare me if it hadn't been heat treated after welding. |

|

|

Dan Merrickwrote: Indeed, a weld filled with ER4130 requires mandatory subsequent heat treatments. There are other fillers one can use to avoid the need of post heat treatments, but you loose tensile strength and in the scope of my build I already needed to heat treat the piton, so it was a no brainer choice for me. Welds prior to the first heat treatment. Initial treatment, followed by a water quench. subsequent tempering process, soaked at a particular temperature to stress relive and give the piton its final spring characteristics.

Verification that the "cooking recipe" adds up to my indented Rockwell hardness. I tested this one to failure, first pull the top sling broke (9/16 super tape), second pull the bottom sling broke, third pull the aluminum oval carabineer clipped into the top hole failed, it was backed up by the 1/4" dyneema cord which failed(I am feeling like an anomaly happened here?), third pull I used two steel quick links, the piton failed at my predicted (mathematically) spot of failure (lower clip hole). |

|

|

I want some!!!!!! |

|

|

Very nice! Are you able to do the die cutting and stamping yourself or are you farming that out? I'm too cheap to have a commercial hardness tester but I do have a home fabricobbled Brinell tester and a calibrated hardness block to check it against. |

|

|

Dan, I’m doing all of it in house, I’m able to produce the tool, die, jig and fixtures here. It might not be the most efficient way, but it allows me to constantly reform what I’m working on. This will not be a high production item, I’ll make batches ever so often. The hardness tester is a neat tool, but there are other methods that can circumnavigation the need for one under many applications. I am a big fan of using the oxidation color spectrum once I gain a good feel for how a particular alloy will react. |

|

|

My fabrication is anything but efficient. I would suggest using an oil for quenching. Water can leave things rusty and the vapor envelope can slow cooling (this might not be an issue with the thinner material you are using). I used to use old motor oil which, after tempering, left a nice black oxide finish. Smoking hot motor oil stinks pretty bad though. When we moved in 2021, I got rid of the old soup pot of motor oil and looked for an affordable substitute which turned out to be canola oil. (Gallons of canola oil are cheap at Walmart.) The canola oil didn't produce the black finish so I researched that figuring some additive to the motor oil was acting as a catalyst. It turns out that the stuff gun makers use to make a black oxide finish uses phosphate and zinc compounds which are also common motor oil additives. Modern motor oil does not have as much of these additives as were used in the past so classic car enthusiasts add them. I bought some ZZDP oil additive (found on Amazon) and added it to my canola oil. Now I get the black oxide finish that I like. |

|

|

That’s really great info Dan! I appreciate it.

very fascinating about the phosphate and zinc compounds, I use old motor oil when I’m quenching O1 tool steel to make some of the tools I use to make these pitons, but I loose that protective oxide when I’m preparing them for final heat treatments. It’s a bunch of fun stuff. |

|

|

|

|

|

Cool! Ever thought about making a die to mimic the Z tip of a leeper vs the smc shallow angle? More work for sure but more contact points and greater "springyness" perhaps? |

|

|

wake and bakewrote: I had not considered the z-ton profile, however if it is something you are interested in, send me a private message and we can discuss making several. |

|

|

Is there a order list forming? I’d love to add some to the rack |

|

|

Kristoffer Wickstromwrote: I am not sure it would be ideal for loos flakes as the Z shape will be considerably more springy than the shallow angle -might be worth modifying a leeper pin into a beak and putting it on someones rack for their next wall? |

Continue with onX Maps

Continue with onX Maps Sign in with Facebook

Sign in with Facebook