Repair the damaged sheath on your climbing rope

|

|

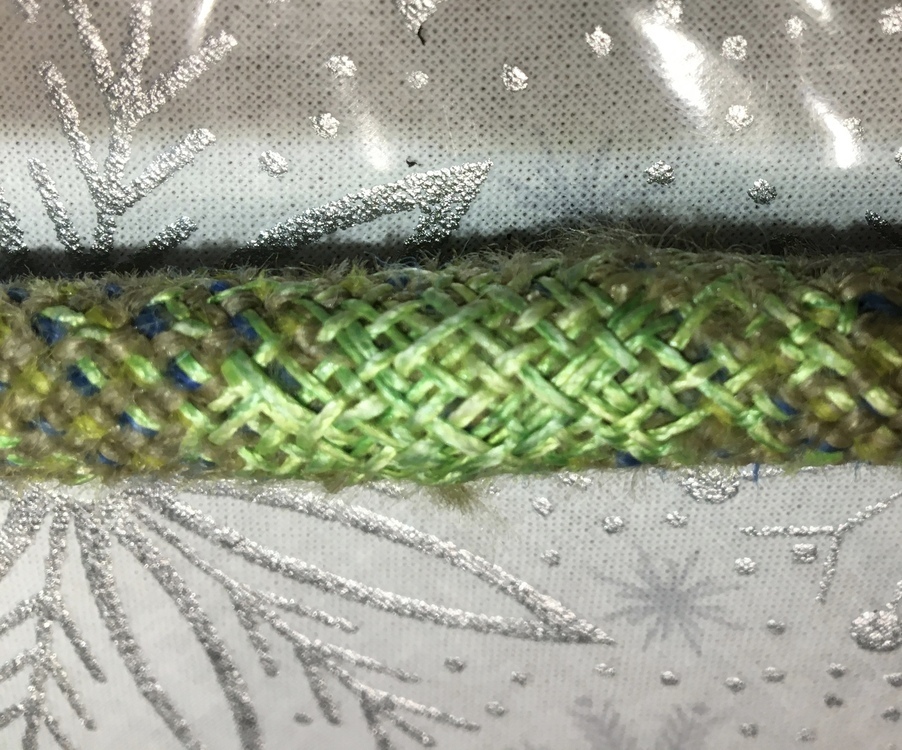

I repair ropes all of the time. It is a great way to be environmentally friendly and save money. When repairing an area that is just fuzzy and weak I do a less dense more spread out weave into the sheath. In this photo the sheath was excessively damaged in an area that included about 20% of the rope circumference. Continued use would have destroyed it. The core was undamaged, but easily visible. It was not nearly as damaged as the orange rope shown below. I used green dyneema fishing line and followed the direction of the yarns in the sheath. In the central area of the repair I didn't run the needle under the most damaged yarns. I did all parallel lines in one direction first, then all the lines in the other parallel second while weaving the needle in and out through the first initial lines. In the edges of the repair you will see places where my green line weaves in and out of the sheath strands. The rope above had severe damage in a very small area, but my repair is smooth enough I don't even notice it when rappelling, and barely do so when belaying. This repair is only on this side of the rope. I only go all the way around the rope when doing a less dense pattern. This is to avoid causing a thick, stiff section in the rope. Don't pull tightly with the needle. I don't do repairs if the core is damaged. If the core is bulging out of a sheath tear, that is very challenging to deal with. Unicore ropes help avoid this. This dyneema fishing line is my favorite but you will get equal results with the much cheaper 8 or 9 strand line instead of the 16 strand. Ebay is also a good source. I find .45mm 130lb line is ideal. The repairs last forever. In the link they simply specify PE line. This is short for UHMWPE which has the trade names of Dyneema or Spectra. It will take you some practice to get repairs as nice as the one above! edit: Testing Results - These were done in February 2023, a year after the original posts. I used a new rope for testing. In the photo I cut through half the sheath strands without damaging the core. When I broke it on my pull tester I was surprised to find the breaking strength was only reduced by 10% compared to a control test break with an undamaged section. This particular half-rope has a very thick sheath so I would have assumed a lot of its strength to be in the sheath. Above I cut through half the sheath again without damaging the core. The repair is woven through the sheath only, it does not disturb the core. You will see that there are far less repair threads than cut threads. I can only put in a certain density of repair threads before a lump is made that is difficult to rappel or belay past. This particular rope has a tightly woven sheath(Edelweiss) where it is increasingly tight and difficult to pass the needle into the sheath as the material is added. You can add a higher density with a loosely woven sheath. The repair was positioned in the most vulnerable place on the test rig. It broke at almost exactly the same force as the earlier test on an equally damaged piece that had no repairs. The repair threads caused no additional damage to the sheath. It was evident they broke before the rest of the sheath or the core did. In his third post below(made previous to this date) Desert Rock Sports wrote about the repair on the top green rope: If you want to really just isolate that section so it doesn't stretch like the rest of the rope, you will have to do quite a bit of reinforcement making sure they are long enough in the length of the rope to transfer the load, and enough of them, and that they are tensioned correctly (balanced) or just the most taught ones may break when the rope tries to stretch. If you have a good way to do that and know how much is enough, great. My take on the test: I have to completely agree with Desert Rock Sports analysis in the post excerpt above. One repair test obviously is a tiny sample but I have become convinced that it would be extremely difficult to make a repair that would restore the rope to its full strength. I am reasonably convinced that as long as you don't sew through the core, this type of repair method is unlikely to either weaken or strengthen the rope. My buddy did his first repair on this rope of his above. Nice! This rope had excessive abrasion in the repair area that would have continued to deteriorate quickly. The repair completely stopped the damage from progressing. We have used this rope forever, both before the repair and after. I have climbed on dozens and dozens of ropes. I love this one the most. It has perfect handling and with the exception of the damage shown, has been almost impervious to wear. The fuzzing and breakdown was stopped before any significant strength was lost. A well loved rope saved! My take continued: I think this type of repair method is highly useful for expeditions where you don't have replacements for damaged ropes. You can even do a really quick crude version of this while on the wall so that you can repair a heavily damaged sheath that would otherwise be hard to rappel on. I have done a lot of repairs including quick ugly ones in the field. They all make the rope hold up a long time. I have had great luck climbing on repaired ropes that had abraded areas or light sheath damage where the strength of the rope is only slightly reduced. I would never attempt to repair a rope with core damage. I would not do repairs for the heavy damage shown on the orange rope except for expedition type scenarios, or for getting down a wall. |

|

|

I’m sure this post will get some safety nazis hackles raised. Thanks for posting, I didn’t know this was doable. I probably won’t ever do this as usually by the time I coreshot a rope it’s on its last legs. But interesting nonetheless! |

|

|

Do you have a link to a page showing the whole process? I’d be curious to learn more. This could be good info to have on long remote expeditions where it isn’t possible to just run to the store and buy a new rope. I’ve climbed on many core shot ropes that are just wrapped in cloth tape or I’ve taken a lighter to cauterize the frayed section. Both “fixes” are less than ideal. |

|

|

I will have to make a page to show the process. Give me a few days I'm crazy busy right now. |

|

|

Yeah, don't do this. Especially don't do this with dyneema. Had you used yarns with material and twist matching the strength and stretch of the original yarns, and extended them far enough, they would basically be a form of splice... but the bulk would be higher. |

|

|

hopefully some technical people from climbing rope manufacturing will weight in......or maybe some textile engineers |

|

|

Arbitrary “YGD!” |

|

|

Let's put it to the test! Would you be willing to send a rope to one of the people who make videos about climbing gear (e.g., HowNOT2)? |

|

|

Desert Rock Sports wrote: So would a better idea would be to use yarn from an old rope? |

|

|

SEND IT TO RYAN JENKS! This is perfect for Science. it's a very cool and ingenious solution, but there's a potential failure mode. Test it! Test it! Test it! |

|

|

Mikey, yes. It would be closer to the stretch needed, friction coefficient. |

|

|

Desert Rock Sports wrote: Again, I think if you are able to go buy a new rope that should obviously be the very best and first option. If that option doesn't exist and not having a usable rope means the end of a multi-month remote expedition I think it is an interesting possible solution. Not sure how much time you have spent in the alpine and or on expeditions but sometimes compromises that involve safety are made that wouldn't be made in other situations.

Isn't this similar to when the roped hasn't been patched? The side missing the sheath isn't able to hold any load so the good side will for sure be holding all of the load. If a patch is able to absorb some of the load wouldn't that be better than none of the load? I've actually chatted with a rope manufacturer about designing/creating some sort of temporary fix for core shot ropes. I had a few ideas, first being a slide on patch that is similar to "Chinese Fingercuffs" with the inside of the sleeve having little teeth that dig in to the sheath of the rope to hold it in place. Other idea was a similar product to shrink wrap for electrical wires. Slide the shrink wrap over the damaged area and heat it up with a lighter. Third was some sort a brush on liquid rubber coating. Unfortunately the market probably wouldn't really support any of these products because it usually makes more sense to just replace the rope. |

|

|

Desert Rock Sports wrote: Localised stretching of this small area is a non issue. The dyneema thread won't cut into any yarns from the rope. It's just not going to happen. Worst case scenario in a dynamic fall the disproportionate stretch in the damaged section of rope causes the dyneema yarn to pull out from the splice. Best case scenario it shields the core shot from being loaded directly, allows for significantly easier rappelling and protects the core from abrasion. I would suggest using polyester instead of nylon or dyneema as the higher friction of polyester should allow the patch to load the rope better and carry the forces through the patch rather than slipping. I think the best thing we could reliably achieve here would be to create a static spot on the rope which would allow the sheath either side of the damage to act as a continuous piece. Reweaving a braid by hand is allot of work and time, good idea for expeds with lots of time at base camp, bad idea for being green. |

|

|

I think sending a sample to be tested is a great idea! Like I said I'm crazy busy right now so it might be as much as a month before I get it done. Testing will come after that. I will send some PM's to those who've responded to alert them. I will also post here. With practice a repair takes anywhere from 10 minutes to an hour depending on how extensive it is. The one pictured was about 30 minutes. If it were done in the field just well enough to get by, it would have taken 15 minutes. |

|

|

Polyester will be higher friction than dyneema, but nylon stretches more. |

|

|

To elaborate, I think the interesting testable question is not whether the repaired section is as strong as an undamaged rope (I doubt it), but whether the repair is stronger or weaker than a similarly damaged section without any repair. Or, to expand the study, whether it's stronger than a section repaired with tape or something else. I think that DRS might be hypothesizing that the repair would be weaker than leaving the damaged section alone. I think you would need a way to damage a rope in a consistent way in order to test this. Maybe slice the same number of sheath/core strands with a razor? Or hold it up to a belt sander for a consistent amount of time at a consistent pressure? |

|

|

It is testable, well kinda. |

|

|

This is testable in so many way, using a matindale abrasion tester you can wear the rope to 3 levels, one heavily worn(maybe 3-4mm of fuzz), core visible (less than 1cm²), core very visible (5cm²). You would then test this with 5 different materials, dyneema, kevlar, polyester, nylon and nylon from rope. Test would simply be your standard uiaa ff1.77, you may also want to repeat this test with the damaged section over a carabiner. This would require allot of tests to get a statistically significant sample size and its something I don't think Ryan(HN2) would really be able to really get any good conclusion from his tests unless he was willing to spend days weaving all the samples needed. The only uncontrollable variable is tension as it is done by hand, weave density and pattern can be controlled by simply sticking with the ropes original weave structure. But the reality is, non of this is going to happen, adding extra material is not going to weaken your rope unless you fuck with the coreif its all you can do on an expedition it seems like a great idea in a pinch. |

|

|

I'm just chiming in to say well done on craftsmanship. I can imaging the needlework required for a patch job like that and know I do not have that skill (without tons of practice). I wouldn't be stoked to climb on that rope, but like Mikey said on an expedition there is a time and a place, good work! |

|

|

I imagine some of the stretch in the repair patch is due to the looseness of the weave creating give in addition to the inherent stretch of the material. This seems like a really nice solution to extend the life of a prematurely damaged rope until it can be replaced. Would sheath strands from something like this make a good patch material? |

|

|

Ryan Never climbs wrote: I’ve been doing that for years. I use a thick cotton poly thread, doubled up, just use a blunt nose needle to weave thru the sheath. The thing I like about it is you can easily feel it when it runs through your fingers. |

Continue with onX Maps

Continue with onX Maps Sign in with Facebook

Sign in with Facebook