Failure point on Micro nuts

|

|

Long Ranger wrote:

|

|

|

Max Manson wrote: I’ve seen my share of those too. A common weak point is where the soldered wire exits the nut—fatigue from “rough” removal and repeated bending at the same point. Be careful removing them so they can do their job, tough as it is. |

|

|

|

|

|

Zachary Zwick wrote: But there is - DMM IMPS #1 is 4-5mm wide & holds 4kN. "Bigger" micros from that set are 5kN & up. That's basically your answer if you want strong micros. Maybe the answer to your question is that soldering the wire into the nut is the best practical thing to do. The other side to that is, if you're going to mass produce the thing, you HAVE to work with offerings from existing suppliers. You may very well be right that there may be some weird Beryllium alloy or something that would perform better than steel for that application. However if it's not already commercially available, no one is going to make any profit engineering & producing both the end product (the nuts) AND the wire that goes into it. Even if you outsource the production of the hypothetical Beryllium alloy wire to some company that works with this - if it's not part of their standard products, they'll charge you the moon for it, because it's a lot of cost for them to make that for you in such (relatively) small quantities. And then sourcing becomes precarious for you - if you have something custom made, you become dependent on that single supplier, or the very few others who COULD produce it for you. I've worked on stuff that required non-standard pieces, and it will drive your costs through the roof pretty quickly, not to mention productions delays due to sourcing issues from time to time....

I certainly wouldn't. I would bet that it may have a market for very few trad climbers, but I would also bet that a lot of the more experienced climbers wouldn't necessarily be interested in it. Because, as the DMM answer alluded to, while the strength rating is important, most of the time the limiting factor will be the ultra-tight margins you have for the placement to hold, even if the piece doesn't break. Because of concentration of forces on a small surface on the rock, which is more likely to reach its breaking strength, and also deformation of the head of the nut. And that last one is pretty hard to navigate, because if you don't deform at all, the nut won't bite well and will be harder to place/set. If it deforms too much, because of the tight margins, it's likely to slip through. |

|

|

There are stronger flexible cables out there but they come with their own problems and cost, tungsten cables for example in the medical industry but I've no doubt if you have ask the price you can't afford it! |

|

|

Sounds perfect for a small made to order cottage industry business with an 18 month wait time! Island Lilliputs! |

|

|

Well, Ryan made a video about it… sort of. Didn’t actually test the smallest ones unfortunately, but looks like all the nuts were failing on the carabiner side not the nut head side |

|

|

Zachary Zwick wrote: Not quite. Small swaged nuts broke at the head (as predicted). Everything else breaks at the carabiner. |

|

|

"Tests have shown that whenever a sling body is bent around a diameter, the strength of the sling is decreased. In order to maintain full basket capacity of a standard wire rope sling, one that is fabricated from 6X19 or 6X36 class wire rope, the diameter of the object being basketed must be 25 times the diameter of the sling rope. For smaller D/d ratios the basket capacity must be reduced. D/d ratio is the ratio of the diameter around which the sling is bent divided by the body diameter of the sling." https://www.americanriggers.com/wire-rope-slings https://acculift.com/wire-rope-the-wear-and-tear-you-need-to-watch-for/ |

|

|

I broke a number 2 stopper wire at the head. My mistake was keeping a static daisy chain clipped to it as I rocked on the next Lowe Ball trying to place the next piece. The Ball slipped out of the piton scar and I fell on the stopper. Force from the daisy chain broke it. I bought a set of steel nuts after that. |

|

|

#2 RP/IMP rated to 5kn #3 BD steel nicro stopper rated to 5kn Purple Metolious TCU rated to 5kn All three will hold multiple ordinary falls in hard rock. Think i trusted the small nuts well before I trusted the small cams. Of course i owned small nuts well before the purple TCU was available. |

|

|

Last year my friend took a series of whips on a small BD nut (steel not brass) on Rubicon in jtree. It held each time until some unusually hard crystal / irregularity in the rock gouged a channel down the entire face of the nut and it pulled out. Wish I had a pic of it, was pretty wild. |

|

|

How Not 2 Highline in real rock snapping nuts, including some tiny ones. |

|

|

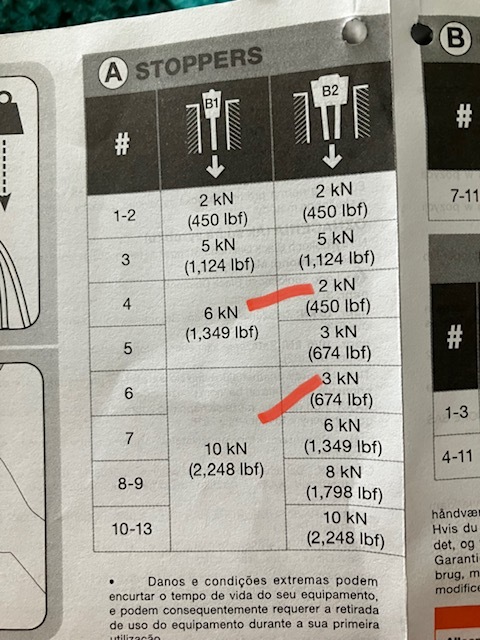

Tighter cable bend at the smaller nuts + smaller diameter cable makes them easier to break according to BD. #1 Stopper – rating – 2kN #5 Stopper – rating – 6kN #11 Stopper – rating – 10kN |

|

|

I carry a #3 stopper but not the smaller ones. Soldered nuts dont have the bend on that end and are stronger so thats the best way to go for actual micro nuts. #4, #3 BD micro stopper, #2 RP or IMP. Those nuts hold falls when placed well in good rock. |

|

|

i fell on a small HB offset, maybe the 2nd or 3rd smallest once. i just knew it was going to pull, but then it caught me. then i slowly looked up and it ripped and i fell another maybe 8 feet onto a purple tcu. the wire looked like a crystal had trenched the head. i haven't ever broken a wire, but i have climbed with a few partners who have and they all looked like jon rhoderick's photo. |

|

|

I checked out this link previously posted but didn't see why the rating halves, or more, on some stoppers when it's placed along the more narrow side as in the picture. By the way, black diamond and metolius gear is 25% off at REI right now... |

|

|

Smaller area of metal in contact with rock = higher pressure. |

|

|

I've never had a nut fail in my falls, but I've had rock fail and I've retired teeny aid nuts with suspect cables. The smaller BD offsets have non-stainless cables. While I might not pay $100 extra per nut for an extra 2kn, I would pay an extra $100 per set. 2kn is a lot and medical bills are expensive. |

Continue with onX Maps

Continue with onX Maps Sign in with Facebook

Sign in with Facebook