faster hand drilling

|

|

Hey everyone, Legends from the days of yore report some freakishly fast drilling times for 1/4" bolts, and some say it was in part due to superior drilling set ups compared to SDS carbide tipped bits. What's the situation now? Does basically everyone use a Petzl drill and SDS bits because they are so widely available? Is it worth putting together a different rig, if you wanted the fastest drill for drilling 1/4" pull-and-replace from stances? Also, from what I've seen, the bit of choice was an A taper HSS, which are now unavailable. Is there anything that makes modern HSS bits unusable for hand drilling? Either in type of shaft, or shape of the flutes/tip? I'd be willing to fab a custom drill holder, and reshape bits, but the fact that I've never heard of anyone using modern HSS bits makes me question if they're suitable. All input is welcome. Curious to hear from anyone who has hand drilled with both an old school setup as well as modern, and could give a comparison. Jonathan |

|

|

Yes, sharp HSS bits with chisel tips can drill much faster than SDS carbide bits, depending on rock type and bolt size (softer rock can be drilled quickly with SDS so HSS is not needed). HSS bits in 1/4" (actually 17/64") in granite can be WAY faster, I found 3/8" (25/64") to only be slightly faster than SDS (in Yosemite granite). There are a bunch of reasons they're not used frequently: - the bits are fragile and don't last long. If you are sloppy with your drilling technique you can snap them off in the hole. Also if you are planning to yard on the drill bit to rest once the bit is in the rock a little, that's fine with an SDS but marginal with HSS. - you need a Hurricane drill or another drill with swappable collets (or A-taper bits for an A-taper drill), and you need to get the correct collet for the bits you're using. Some Hurricane copies were made a few years back, there's a big thread on Supertopo: http://www.supertopo.com/climbing/thread.php?topic_id=1384069&tn=0&mr=0 - you need to grind down a bunch of bits to chisel-tips (takes a while with a bench grinder, have to cool the bits with water). The angle of the chisel tip can be hard to optimize. - if you have 3/8" (25/64") HSS bits and you want to drill out an old 1/4" hole, you have to use an SDS bit until you're all the way through the old hole, the HSS will break. You just use black oxide jobber bits, they are widely available. There are a bunch of tips and tricks - first off is that you need larger drill bits than you think. SDS bits are actually a bit bigger diameter than advertised, so when you get bits for HSS you get 17/64" for 1/4" bolts and 25/64" for 3/8" bolts (25/64" is the collet size that comes with the Hurricane - it is also the correct size for using SDS bits in a Hurricane). Anyway, HSS setups are awesome for doing routes where you'll be doing a lot of lead drilling of 1/4" on granite. Generally you're drilling a single bolt, then swapping bits immediately (assuming you hang/rest on your newly placed bolt). Then you sharpen the bits later (just need a file to do it in camp, or it's super quick with a bench grinder). I always had a Petzl drill with 1/4" SDS bit on my harness in case the HSS bit broke - also I could quickly and easily swap out the 1/4" SDS for a 3/8" SDS bit in case I got to a good stance (or belay stance) so I could place a 3/8" immediately. Anyway, the simplicity, convenience and reliability of a Petzl Rocpec plus SDS bits is super nice. That's why HSS are not commonly seen - also not many folks are putting up long granite slab routes on lead with 1/4" bolts! |

|

|

Thanks for the lowdown Greg. I have heard of the preference for a chisel tip; does that basically mean that you grind the tip of the bit so in profile it is "flat", i.e. not pointed like a wood or metal drilling bit generally is? |

|

|

Greg Barnes wrote: DAB |

|

|

Jonathan Croom wrote: Yes. Part of the reason for the speed (and thus the preference) is that the SDS handles and bit allow for "play" in the bit allowing it to move back and forth in the handle (just like in a rotary hammer drill) So the bit bounces a bit in the hole. This makes SDS faster when in a hammer drill but slower in a hand drill. The chisel tip systems (Hurricane and Rawl) doesn't allow the bit to move and so more of the force travels through the bit into the rock. Though you ca use an SDS bit in a Hurricane, it doesn't work so well because the carbide tips shatter if there's no play. If you're looking for a Hurricane handle Runout Customs miiiiight have some still but I'm not sure. My advice is to stay away from the Rawl handles because those tapered bits for the Rawl handle are getting harder and harder to come by. |

|

|

Thanks for the info everyone, much appreciated. I think I will try building a simple holder for 17/64" bits. So what bevel angle should I aim for when reshaping/sharpening bits? Start somewhere close to a carbide bit, and go from there? Does the best angle depend much on rock type? |

|

|

Jonathan Croom wrote: Yes |

|

|

I recently purchased a Rocpec. For drilling 3/8 bolts in gneiss (hard, but not basalt hard), does anyone have recommendations for drill bit type? My understanding is the sharpened chisel bit are the way to go for non-SDS type drill bit holders, but it's unclear to me of the advantages/disadvantages of different bit types when using an SDS style holder (Sorry for the thread necro). |

|

|

I did a test of sharpened two-cutter carbide SDS bits versus a brand new unmodified four-cutter carbide SDS bits in my rotopec for drilling 3/8 bolts in hard rock. The sharpened two-cutter was about 10% faster than the brand new four-cutter. IE I was placing 3-1/4” deep 3/8” wedge bolts and the drill times were like 27min vs 30min. |

|

|

Also, how much does hammer matter? If the hammer is hard enough where it's not denting from the drill holder, do I really need to buy a $100+ climbing hammer? |

|

|

For my tests I was using a Petzl Tam Tam. Its not a very beefy hammer but I would say the sharpened two cutter bits prefer a faster hammering pace over hammer force, so a small hammer is good for them. If you hit too hard they tend to dig in and bind up. The four-cutter bits were a bit more resilient and may have benefitted from a larger hammer? My guess is it doesn't matter though. |

|

|

Could someone please post a picture of their modified drill bit that they're happy with? Can't seem to find a photo on the interwebs. |

|

|

I've spent a lot of time trying to figure out how to drill faster and have come up with some data, ideas and opinions. I'm sure many people will disagree or have differing results. I have written up a 10 page white paper on this with references and pictures but it is impossibly dull and confusing to read. Sharper bits are faster whether they are carbide or HSS. There are at least two variables here, the sharpness of the edge and the angle between the two faces. A narrow wedge and sharp edge drill faster but will chip and dull more easily. Changing bits wastes time and the only way to drill fast is to keep pounding. Carbide bits can be sharpened `on a silicon carbide (usually green) grinding wheel or with diamond files but I quit sharpening them because they chip and shatter so easily. I suspect that the carbide rock drill manufacturers have optimized their tip geometry. ¼” bits are always slower than similar 3/8” bits. Likely factors may be the small shank and constrained space at the rock face resulting in an inefficient crater in the rock for each blow. ¼” bolts are usually faster to place because the hole doesn’t need to be as deep. |

|

|

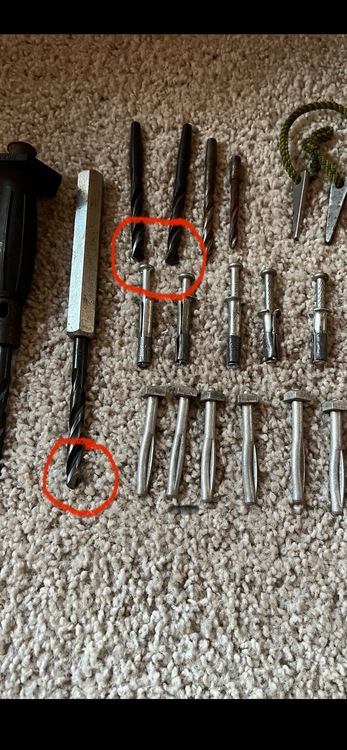

Jon.R wrote: Zoom in to see the bits. They are part of an old 60'S?? Star bolting kit. They work well but bind up kinda easily the deeper you drill. No, I'm not going to put those Dryvns or split shafts on any routes. They were include when I bough the drill - just out of the photo. Non SDS so you have to bang those wedges hard behind the bits to remove them. |

|

|

|

|

|

A look at my friend's 1/4" drill and holder mentioned above. The bit is held in by a spring or roll pin and it isn't practical to change it while dangling on a rock face. He has a machine shop so it's easy for him to make and carry a couple of them. |

|

|

Dan Merrick wrote: Thanks for all the info, Dan! That bit doesn't look like any of the bits I've seen at the hardware store, can you explain what type that is? Do they make RocPec compatible versions of this? |

|

|

Jon.R wrote: The bit is made from a piece of drill blank. If you make one you would want to choose a high speed steel (HSS) that has been hardened. The only magic about HSS is that you can get it hot without ruining the hardness, you can actually get it hot enough so there is some redness and it won't hurt it. You want HSS so you can grind it into whatever shape you want. McMaster-Carr is a good source for drill blanks: https://www.mcmaster.com/products/steel-drill-blanks/ The bit isn't RocPec (SDS-Plus) compatible but in thinking about it maybe you could cut the SDS part off an old bit, drill, ream and insert the HSS bit with a press fit. This might work for 1/4" but not larger. I'll have to go out in the shop and see if I can do it - I probably don't have the right reamer. Without SDS comparability, you would need a Hurricane holder with appropriate collet like Greg mentions above or make a holder like my friend has done. On a side note, there are four standard sizes of SDS (Special Direct System): SDS Quick, SDS-plus, SDS-Top and SDS-max. SDS-plus is the most common. |

|

|

I guess the question I'm looking for a straight ahead answer is, while recognizing that there probably isn't one, is if using a Rocpec, and without access to a proper metal shop (though I could get a grinding wheel), what's the best bit option for me? From reviewing other threads I didn't see a clear consensus on the best type of holder, though there were lots of strong opinions from lots of experienced people. FWIW I installed my 2nd ever 3/8" 3" wedge bolt in hard gneiss in 40 min, on rappel with a 23 oz hammer and am a 140 lb desk jockey. Am curious as how much my equipment is responsible for my drill times as oppose to experience / general light duty-ness. |

|

|

kudos to you for hand drilling. The drill bit and the holder make minor differences, usually 5% to 10%. The right hammer for you can make a bigger difference, up to 50% mostly due to weight. Going from a 24 Oz hammer to a ridiculously heavy 2 pound single jack (actual weight 2 lb 7 oz or 39 oz) cut my drilling speed by 60% because it was too heavy and I couldn't keep going. You can sharpen bits but if you do you will also waste more time changing bits. I stick to factory sharp 2 flute carbide SDS bits. The biggest variable is you. You need to keep pounding and hit hard. If you find you can't keep going, slow your cadence and focus on indexing and hard hitting. You need to stoically suffer for a little while. Not indexing wastes a lot of time and work, the second strike in one position is mostly wasted. I've done testing to look at this too. Video: Hand drilling a rock climbing anchor in 4 minutes 30 seconds |

|

|

Thanks again, really appreciate it. |

Continue with onX Maps

Continue with onX Maps Sign in with Facebook

Sign in with Facebook