Cordelette vs Accessory Cord

|

|

Not sure if this is a dumb question or if it has been covered. But when looking for this item, I found Cordelette specific, and also Accessory Cord. The Cordelette was smaller in diameter than the accessory cord by 1mm, yet it was advertised to have a greater load rating than pre-cut accessory cord by about 300-400 lbs (in a single strand, not rated as in magic W formation by my interpenetration on both packages). |

|

|

If you are reffering to the spools of nylon cord at the climbing shop versus the packages of cordalette, you can use either one. |

|

|

Paul Reineck wrote:Not sure if this is a dumb question or if it has been covered. But when looking for this item, I found Cordelette specific, and also Accessory Cord. The Cordelette was smaller in diameter than the accessory cord by 1mm, yet it was advertised to have a greater load rating than pre-cut accessory cord by about 300-400 lbsPaul there are different materials that can go into a product. Whether the maker is calling it "Cordelette" or "Accessory" doesn't really tell you much; though it may intend to mean one is a good fit for anchor rigging, the other could be a good fit for other purposes. Cords usually have two portions, a sheath and a core. These two can be combined usually with these materials, for example: nylon, kevlar, polyester, dyneema/spectra, polypropylene, &/or technora -- depending on the certification and application intended. There are also sheaths that have reflective properties that can glow after light exposure and/or when a light is shined on them (like using these for tent guy-lines so you don't clothesline yourself or trip over them in the dark; or you need to keep a visual on one after darkness sets in, like a safety fixed line that people need to find). What is important is considering what will go into your safety factor when considering rigging, most obvious is strength; if just top roping usually anything that is rated will work just fine. But, if moving to other applications where you look at subjecting an anchor to energy, load distribution and material resiliency become more important. My preference is nylon for most cord applications due to its resiliency, longevity, and cost when considering many different types of uses it might perform while climbing recreationally for more than just top roping; mid wall anchor rigs/work stations, elasticity for load distribution, knotting effects, self & buddy rescue, bail/rap rigs, v or a threading, maybe convert into sling lead rigs, use as an extender/lanyard for anchor tie-in to work on a ledge or traverse line; cord can have many uses. I think nylon goes good with just about all of them and it's easy to replace. |

|

|

cordelettes are an amazing versatile tool. so many applications if you make your own from the spool. they are cheaper this way and then you can tie your own prefered lengths. I always have them with me in the mountains because for me they are disposable if need be. I tend to make mine a bit longer, I can always cut the cord to make a prussik in a pinch or use it to sling an anchor or even imporve existing anchors by cutting tat and replacing in an inexpensive matter. The rescue applications are endless and if you untie your cordelette and put overhand or eight bights you can make your own webellete when short on material to maximize its extention and use. |

|

|

What is military grade webbing, is that like medical grade marijuana or something? |

|

|

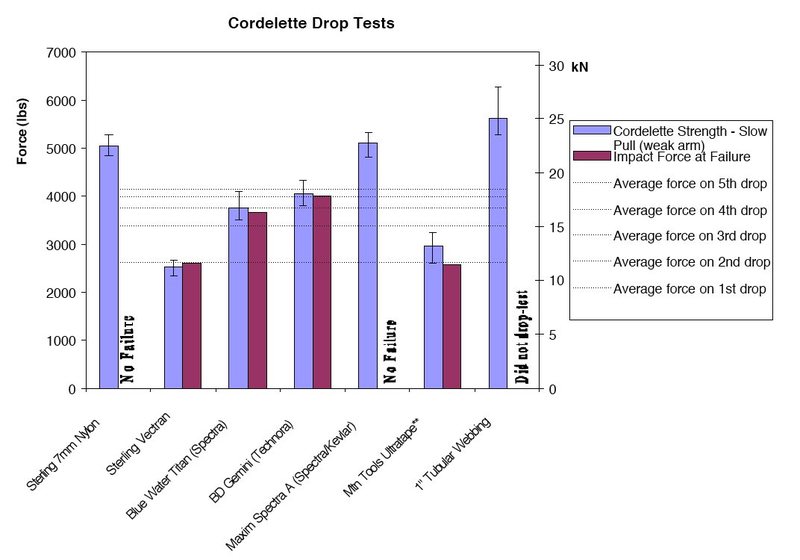

Buff is pretty much right on. Years ago, I used a variety of different cordelettes that were specifically made for building anchors. In general, these cords are skinny (5-6mm), but feel stiffer than regular old accessory cord. Also, when comparing the strength with equal diameter, the cordelettes are usually a bit stronger. Thus, on the surface, it would seem like the cordelette is better. BUT, and this is a big but, I have read some testing data where they show the breaking strengths of accessory cord and various brands of specialized cordelettes versus bend cycles. |

|

|

To expand on J. Albers bending, A great example is what you do with a credit card when you are done with it. You bend it back and forth and eventually it breaks and you throw it away. |

|

|

JPVallone wrote:What is military grade webbing, is that like medical grade marijuana or something?Understanding this has already been covered, but when viewing the difference between "military grade" and "climbing grade" the weave was more aggressive and the webbing was a bit thicker on the military grade stuff. Also understanding it was heavier, I'm not doing extensive mountaineering with this so weight isn't a big factor. Since it was only $.02 per foot more expensive, it seemed the wiser way to go. |

|

|

J. Albers wrote:Buff is pretty much right on. Years ago, I used a variety of different cordelettes that were specifically made for building anchors. In general, these cords are skinny (5-6mm), but feel stiffer than regular old accessory cord. Also, when comparing the strength with equal diameter, the cordelettes are usually a bit stronger. Thus, on the surface, it would seem like the cordelette is better. BUT, and this is a big but, I have read some testing data where they show the breaking strengths of accessory cord and various brands of specialized cordelettes versus bend cycles. Essentially a bend cycle occurs every time you bend the cord to clip a piece of pro or tie a knot. The results are sobering. The specialized cords that start out with superior breaking strength VERY quickly degrade to a surprising weak strength with very few bending cycles. The accessory cord on the other hand shows virtually no degradation of strength with bending. After reading through all of this, I came to the conclusion that I was willing to lug a 7mm setup around because the 5mm specialized stuff needed replacement in a season or less. Thus, I pretty much stick to Sterling's 7mm cordelette at this point (it is particularly strong, but basic, accessory cord).Great explanation. Thanks. Definitely raises some good points, and has me thinking about what I bought. I DID notice that the 6mm cord that I bought did have a different weave, and it IS stiffer in the hand than standard accessory cord. I dug the packaging out (don't know why I kept it) and tried to find the material construction on it but it doesn't say. All I see on it is that it's made by BlueWater, it's 7mm X 20ft RD Static Cordelette. It also gives tensile strength, and force load ratings in a few different configurations. The accessory cord (labeled as such) was generally 8mm on the spool and prepackaged. And the pliability was much softer. . . . so does that mean I have the material that quickly wears out from flex-fatigue? I suppose a quick email to BlueWater would answer the material construction question. |

|

|

Blue Water replied amazingly quick to my email inquiry. Blue Water wrote:The Cordelette has a polyester sheath/nylon core while the regular accessory cord has a nylon sheath/nylon core. |

|

|

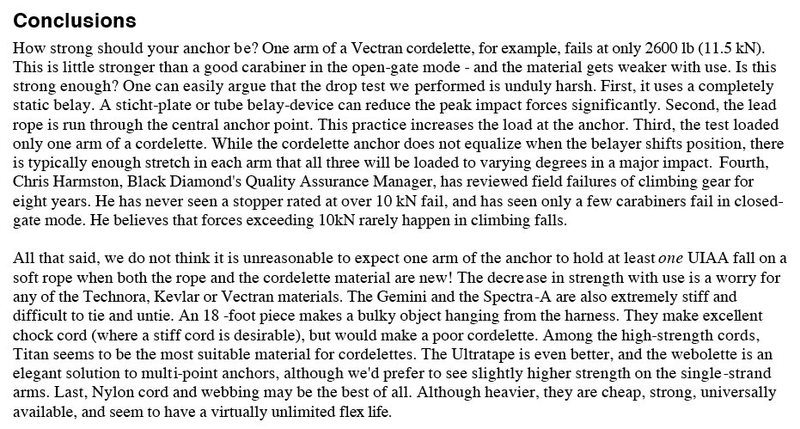

Paul, you surely have one of the specialty cords that is strong at first, but loses strength quickly. I am posting two plots and then conclusions from the tests that I mentioned earlier. The testing was done by BD employees Tom Moyer, Paul Tusting, and Chris Harmston. Cheers. |

|

|

Mr. Albers, |

|

|

Well, I'm not completely sure, but my feeling is that not all accessory cords are the same, though I could be wrong about this. For instance, look at the Bluewater website under 7mm accessory cord and 7mm cordelette cord. They have two very different breaking strengths, thus I think that the accessory cord that you buy at say REI, is NOT as strong as cordelette specific accessory cord, which is itself different from the thinner 5-6mm specialty cordelettes. Does that all make sense? Therefore, I would stick with either the Bluewater or Sterling cordelette specific 7mm accessory cord, and not standard 7mm accessory cord. I use this cord because I know its strength and I know that it will last a long time. |

|

|

JPVallone wrote:What is military grade webbing, is that like medical grade marijuana or something?Mil-spec webbing is webbing that is manufactured to meet one of the U.S. military's formal specifications for such things. MIL-W-5625, for example, is a standard for tubular nylon webbing that specifies such things as thread material and weight, colors, identification yarns, minimum breaking strength, wear resistance, etc. A PDF of MIL-W-5625 may be found here: everyspec.com/MIL-SPECS/MIL…(MIL-W)/download.php?spec=MIL-W-5625K.014723.pdf |

|

|

Perin Blanchard wrote: Mil-spec webbing is webbing that is manufactured to meet one of the U.S. military's formal specifications for such things. MIL-W-5625, for example, is a standard for tubular nylon webbing that specifies such things as thread material and weight, colors, identification yarns, minimum breaking strength, wear resistance, etc. A PDF of MIL-W-5625 may be found here: everyspec.com/MIL-SPECS/MIL…(MIL-W)/download.php?spec=MIL-W-5625K.014723.pdfI am aware of this, I just think it is a funny term, Does anyone know where to get a military grade climbing rope, Harness, Cams and carabiners, or should I just have all steel carabiners? Basically you need to understand potential forces, loads, scenarios in every circumstance you put yourself in. The big question is, Whether it's your material, your anchor, the holding force of the belay, whatever, IS IT STRONG ENOUGH, In modern equipment and materials the answer is usually yes as long as the application is with in the manufactures recommendations and within our own skill sets and understanding of the techniques and systems applied. Sounds Like Paul is getting himself into basic top rope set ups and out fits. The most force he can put on the anchor assuming an adequate belay is the the weight of a belayer and the climber, 200lb belayer and 200 lb climber, = 400 lbs on the anchor. Is this material strong enough YES. does it matter if material x is stronger than y, in these contexts probablly not , just splitting hairs. More importantly if I am using any of these material, are they being used in a redundant way. I personally don't own any webbing, I have no use for it, The only webbing I is in my slack line in the front yard, Way more uses for cord than webbing. I use anchor ropes and retired climbing ropes cut into anchoring pieces for my more complex top rope settings that require more material and extension to get to a master point. |

|

|

J. Albers wrote:Well, I'm not completely sure, but my feeling is that not all accessory cords are the same, though I could be wrong about this. For instance, look at the Bluewater website under 7mm accessory cord and 7mm cordelette cord. They have two very different breaking strengths, thus I think that the accessory cord that you buy at say REI, is NOT as strong as cordelette specific accessory cord, which is itself different from the thinner 5-6mm specialty cordelettes. Does that all make sense? Therefore, I would stick with either the Bluewater or Sterling cordelette specific 7mm accessory cord, and not standard 7mm accessory cord. I use this cord because I know its strength and I know that it will last a long time. Cheers.I understand that. The stuff I saw at REI (where I bought all this stuff. might as well let the cat out of the bag here) on spools were pretty much all 8mm in diameter. I didn't see anything under 7mm except for things like tiedown cord like what's used for tent guy-lines and whatnot. And the spooled stuff, I'm not sure had load/force ratings on it. Some of the pre-packaged stuff did, and maybe I was just gullible enough to fall for "oh it has a load rating, so it must be good." Unfortunately, the one guy at REI that I go to for questions on gear and stuff like this wasn't there. He's a certified mountain guide and climbing geek, and he seems to have his head on straight with regard to knowledge in gear and locations. So I was stuck with the so-called generic salesman who repeats what he was told at sales clinics. But if what I have will substantially weaken over time to less than 7mm standard accessory cord due to bend cycles and flex-fatigue, then wouldn't it make sense to just get the standard cord over the cordelette specific cord? If the standard cord does not share the wear factors that specific cordelette does . . . BTW, just my luck that Blue Water's website is down so I can't see specifically the differences in load/force ratings between the two. I'll check again in the afternoon. I did see load/force ratings between what I bought and standard accessory cord (as stated in my OP) but I don't think they were of the same brand. This certainly raises questions in my own mind with regard to safety. If what I have weakens substantially over use and time I would have to replace it after maybe 1 season of climbing to maintain a strong master point. As this is essentially the thing that holds everything else together, it's a critical component to the setup. It's something that I don't ever want to screw up on. . . . well, I don't want to screw up on anything with regard to a setup, but the master point is the primary connection between everything else. . . . I dunno. I'm rambling. And tired. I'll shut up and go to bed. :-) |

|

|

Paul, |

|

|

Anyone know what mammut pro-cord is made out of? Their website has all sorts of info about how it it constructed (not kernmantel ) but no indication of the materials that I could find. |

|

|

Rick, that's an interesting concept from MammuTec called the Paraloc system which has a basis in sheeting used in sailing that interlocks the sheath & core. The materials used can be interchangeable as the similar materials I listed above. |

|

|

A couple of vendor sites I went to state that it is nylon. It sure has a soft feel and seems to stretch a little so I would doubt that it is dyneema, kevlar or any of that other fancy stuff. |

|

|

a little off topic but does anyone know if any vendors are using the Paraloc weave to make climbing ropes? Does it even work with dynamic ropes? just curious |

Continue with onX Maps

Continue with onX Maps Sign in with Facebook

Sign in with Facebook