New Sleeve Bolts

|

|

Just wanted to let people know that Climbing Taiwan has done a lot of hard work sourcing and putting together a really decent quality ssleeve bolt of their own that is now for sale at hownotto.com… Now before the skeptics chime in, yes we are under no illusion that climbing Taiwan is not like the bigger hardware seller like Dewalt but they absolutely put together a bolt just the same way as the larger hardware dealers. Just like Dewalt, they buy there bolt components from manufacturers in China. And just like Dewalt and formerly Powers, they picked and chose from different suppliers what components they want in a bolt. When they get the final product they then do a QA/QI process of testing the bolts to make sure they are performing with in acceptable and predictable situations of failure. Now of course CT doesn’t have a process as robust as Dewalt, but they do a decent job of testing their products. Now, if you take their new bolt and you put it next to the common Dewalt sleeve bolt you will see that the CT bolt looks and feels like a much better quality. I have always thought the Powers sleeve bolt looked and felt janky, but always did perform appropriately. I’m sure this will spur healthy discussions, but please take the time to go to HowNot2s website to buy some bolts. Oh, did I tell you…? These 12mm bolts are < $4!!!! https://hownot2.com/products/316-ss-sleeve-bolt?_pos=1&_psq=sleeve+&_ss=e&_v=1.0 |

|

|

Can’t speak for the sleeve bolts, but the wedge anchors they also sell are a much nicer design than the dewalt power studs and tighten up much more consistently. |

|

|

Alex Morano wrote: That’s good to know… I have some of those but have not used them yet. |

|

|

I am very happy with the performance of the wedge bolts so far. I’ve place between 20-30 and plan on using the CT wedge bolts moving forward. After seeing the performance of the wedge bolts I’m sure the sleeve bolts are awesome too! And a price hard to beat. So much awesome new gear coming out. It’s a great day to be a developer. |

|

|

i place a lot of 5-piece sleeves, so am interested in any thoughts on the lack of compression ring? the torque washer on powers always seemed nice for (most) people who don't use a torque wrench. knurled cone looks interesting (in a good way). |

|

|

old5ten wrote: Torque washer? |

|

|

Matt King wrote: |

|

|

Greg Barnes wrote: That's an anti-galling washer found on SS bolts. |

|

|

Dan Merrick wrote: Cool, learn something new every day! They tend to break somewhat randomly in my experience. |

|

|

Greg Barnes wrote: actually, according to my torque wrench they break fairly consistently |

|

|

any thoughts on the lack of a compression ring? |

|

|

Greg Barnes wrote: Thanks Greg… |

|

|

Hi. Thanks for everyone’s interest in this sleeve bolt we’ve been testing and sourcing. It took a bit of effort and trying out different components to see which worked best for a more economical design. We went with a hex bolt (partially threaded) over a set screw (fully threaded) due to its superior strength in radial loading (more material). The right sized sleeve took some effort tracking down, we like the raised nubs to help grab onto the rock, and better fitting for a 12mm hole. The straight-knurling on the cone nut help keep the expanding-ends of the sleeve in place. We introduced this sleeve bolt as a budget-friendly option for developers. It’s not meant to replace 5-piece Power Bolt (err…well, 9 if you include the blue sticker), which is a beautiful well-engineered sleeve anchor… (at a price). Our sleeve anchor doesn’t have the “compression ring” which was added for human-error to compensate for over-torquing. Nor does our sleeve anchor cone have a nylon “dust cap” for those not cleaning holes well/at all. In regards to the galling concern, we physically run the nut up-and-down on each hex bolt to ensure the threads are not damaged & to ensure a smooth installation; the washers are lightly lubricated, and so are the hex bolt’s threads. (In general, over-torquing can also initiate galling). All the components are passivated. All the parts are currently manufactured in China. The hex bolt by THE (Tong Hwei Enterprise), a manufacture that other fastener brands have used, e.g Hobson Engineering. We inspect the components and assemble the sleeve bolts here in Taiwan. We currently have 316SS, and 304SS are getting mailed out this week. And plan to stock additional lengths in the future. Do a good install: Clean your holes; torque to the recommended range/value--- proper mechanical anchor installations also rely on friction and appropriate torque values. We are currently working on other sleeve anchor designs as well. (A lot of this info I have been meaning to put into the long-form video, just haven’t found the free time yet). Thanks Matt King for sharing & posting! |

|

|

These look great, Kevin! What additional lengths are you planning on sourcing? |

|

|

Kevin, two questions

2. Have you tried removing these bolts? Any difference in process or ease from the powers bolt? |

|

|

Tal M wrote: They look like they would be pretty easy to remove since the sleeve is one piece and the cone looks to be smaller than the hole diameter unlike original/ss powers 5pc. Loosen the bolt tap it in to release the cone. Fully unscrew the bolt and fish the sleeve and the cone out with a hook tool of some sort (A bike spoke works well for this) |

|

|

Jim Day wrote: Hi Jim! Currently have stocked 12mm(hole diameter) x 80mm(hole depth)(approx 3.15 inches) in 316 and 304. Also have 10mm x 70mm in 316. We are working on getting 12mm x 120mm (approx 4.75 inches) in both 304 and 316. As well as 10mm x 70mm in 304, and 10mm x 120mm in both 304 and 316. We can also get lengths in between, and even shorter. But for now we just wanna stock opposite spectrums. We're getting the HowNOT2 store also stocked up on longer metric SDS 4-cutter bits of 210mm length w/150mm drill depth, (in addition to the 160mm long ones that have a 100mm drill depth they already stock). Useful for also for the longer-leg glue-in bolts on the market too. |

|

|

Kevin Maliczak wrote: 12 x 120 sounds good to me! I'll be on the look out for them |

|

|

Tal M wrote: Hi! Great questions. 1. The 10mm sleeve bolt won't even go inside a 3/8" (9.5mm) hole because the cone itself has an OD of 9.8mm. (And for reference, the 12mm sleeve bolt's cone nut has an OD of 11.9mm or 12mm) Regarding using our 12mm sleeve bolt in a 1/2"(12.7mm) hole, it will just drop straight down in it and wiggle a little. It might not (at first) tighten down at all because the sleeve has nothing to grab against. You could however tighten up the cone nut a little to find the sweet spot where the sleeve ends will have some friction as you tap it in the hole; then you should be able to tighten it. We haven't pull-tested our 12mm sleeve bolts with 1/2" holes yet. I'll add it to the to-do list. But frankly it's not recommended because if the bolt were to get loosened enough + the cone stopped expanding the sleeve sufficiently, the whole bolt could just slide out the oversized hole. ---- Which is something I intentionally do with DIY removable sleeve bolts I make where you cut out tabs on the sleeve (sorta like the flange on the Fixe Triplex) and then drill a slightly oversized hole (e.g 13mm hole for 1/2" sleeve, or 12.5mm hole for a 12mm sleeve.)----In pull tests of my DIY removable sleeve bolts, they can range from full strength breaks to a little under where where they pull out (but like still above 25kN and up, depending on the diameter being tested). 2. So the removability of our sleeve bolt is the same as the Powers in the sense you just unscrew out the hex bolt, and the sleeve + cone are still stuck in the hole. How easy the sleeve can be removed primarily depends on how snug of a fit it has. Basically the harder someone had to hammer a sleeve anchor in, the harder it will be to pull the sleeve out, the same way a few light taps of a sleeve will too have much easier removal---which really is based on the amount of friction. Matt on his YT channel Mountain Mullet talks about sleeve removal techniques HERE.--- We size our sleeves to be semi-snug in the hole, like they will require taps from a hammer, not as hard as inserting a wedge bolt, but not light either. The reason also for this is so they can be placed in overhangs and will not slide out during installation. It also better maximizes surface contact for a better placement and getting more overall strength from the bolt. So, depending on the hole diameter drilled, how straight, or wallowed-out or not, etc. can also affect the ease of removal of the sleeve. So for larger holes, like just using a hole brush can fish out both the sleeve and cone nut. For the right-sized hole, a pair of vice-grip needle nose pliers can also do they job (maybe after drilling out a little notch). For more stubborn sleeves, a 7/16 tap will work for our 12mm sleeves, and a 3/8" tap for the 10mm sleeves. Getting out the cone nut is easy, a hole brush can do the job. |

|

|

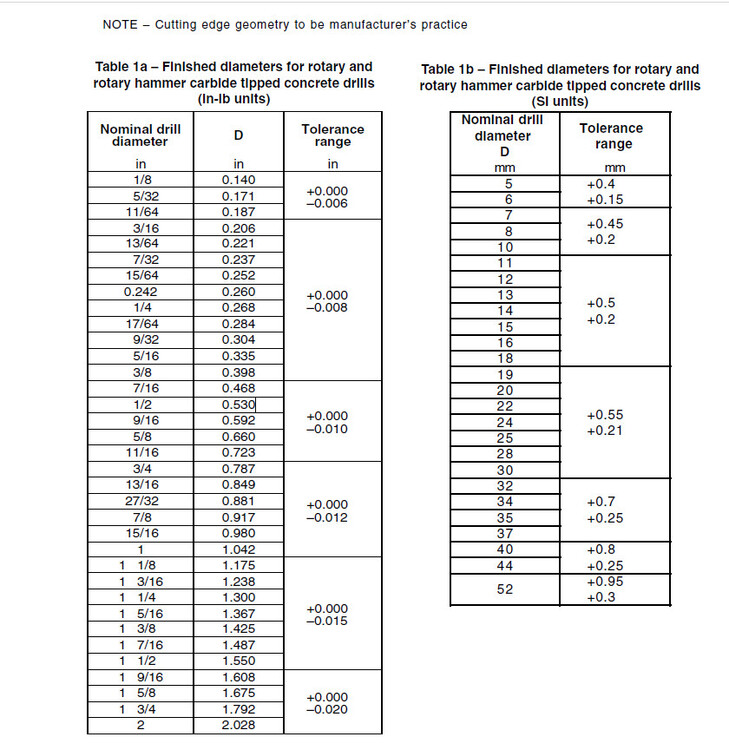

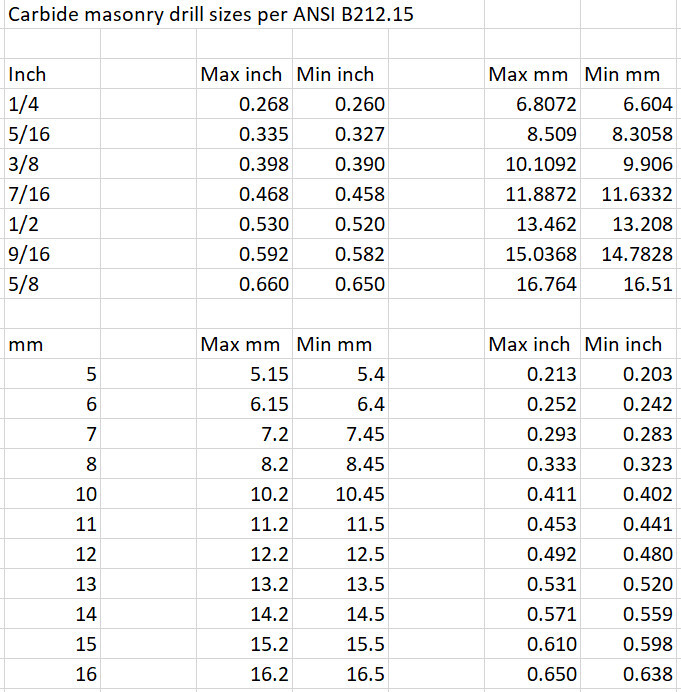

I suppose some people don't know this and perhaps others have forgotten but the ANSI standard B212.15 sets the allowable range for carbide drill bit diameter (chart below). I'm sure there is a similar European standard but I haven't looked it up. All of the bits have a larger diameter than the designated diameter and a bit will always drill a hole larger that itself. |

|

|

Dan Merrick wrote: Great info & chart Dan, thanks for sharing! Just to build on this chart and my previous posts on measurements, the sleeves on our anchors are also wider as well, for example the 12mm is sleeve is more like 12.2mm in outer diameter, give or take. So the measurements stated aren't exact, but generalized to match appropriate sized bits for the appropriate anchor diameter. Using a drill bit that is too small with mechanical anchors risks botching an install, e.g. a 3/8" bit with a 10mm wedge bolt. Worn-down bits can be a culprit too. Whatever the case, our 10mm sleeve anchor won't fit in a 3/8" hole I drilled. And having to beat a bolt in with a hammer to the point it's sorta deforming can be a red flag too. |

Continue with onX Maps

Continue with onX Maps Sign in with Facebook

Sign in with Facebook