Photos of BEAUTIFUL HARDWARE

|

|

Luke Bertelsen wrote: To better prevent the rare yet possible "double clip". Though, it's not a real particular concern of mine, since these anchors are on single pitch routes where the anchor is visible. I just enjoy trying a variety of anchor styles on some of my routes whether the bolts are vertical or horizontal, (primarily rock quality being the determining factor). |

|

|

You placed em in line, just use 1 QL and a 1 lower off on each, save ~$25-30 in hardware... |

|

|

Shawn S wrote: Pros and cons to every bolt/anchor system. I'm not disagreeing with you that more savings for inline and using less hardware to safely get a climber down. But if you're curious about the total material cost for the 2nd picture where I'm currently living/developing, here's the breakdown: 34 for epoxy, 184 two 6mm Twist Bolts, 45 four chain links, 160 D shackle + 3 SS carabiners, 90 two mallions= NWT$513, which is equivalent to $16.70 USD for everything. With 47+ pages to look back of hardware photos ranging from inexpensive, expensive, beautiful, practical, overkill, user-friendly, open-system, closed-system, single-point,etc., I was simply sharing some other anchor setup I found unique and affordable for my budget/accessibility. |

|

|

More $$$ more Routes! Dang super jealous, 2 twist bolts w/shipping is more than $16 USD for me... And of course! Great to see more beautiful hardware! Glad you used thread-locker on the D-shackle! |

|

|

|

|

|

DrRockso RRG wrote: Twist Bolts + Mussys at the RRG, KY. Really nice work with the glue and masking the rock here! Beautiful indeed! |

|

|

Beautiful Hardware, not bolt related, a personal Progression of Attachment for Solo Belay Devices First there was a standard locking carabiner. Easy to use, but had loadbearing issues. Could crossload. There should be something better and as easy to use. Then I had a little spare cash and got a Notch V3 Quickie. Lovely to look at, difficult to use; I noticed they stopped selling them right away. Hard to push the tiny stops in. I was going to carve a wooden tool and hang it on my harness or use my nutpick... But, no. Now I have a Petzl Omni Triact. Sensible design, and it, too, is beautiful. |

|

|

Kicking the thread back to life. No bolting experience whatsoever, but have any of y’all professionals checked out McMaster Carr for chain and mussy hook alternatives? https://www.mcmaster.com/chain/corrosion-resistant-chain-for-lifting |

|

|

Climbing Weasel wrote: Pretty dang pricey. |

|

|

Cody Lee wrote: good shit, thank you. I love the granite at the city but always hate feeling the rope grind into the rock as I'm lowering off. |

|

|

|

|

|

|

|

|

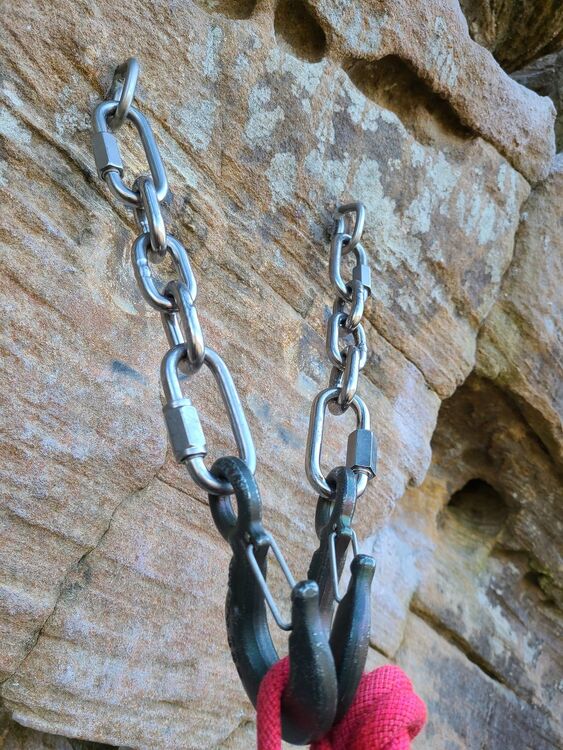

All stainless in on single pitch in RRG. Mussys might be better. If I only used one quick link on each side and the steel carabiners both faced out, do you think I would I have too wide of an angle and or create rope twist when lowering? |

|

|

J- Ru wrote: With the orientation of the lower off points being parallel to the wall instead of perpendicular, this setup will cause twists. Ideally make them one link longer in this case because shortening would twist also for the reason you mentioned. Although the way it is now is worse than if it was too short. |

|

|

J- Ru wrote: As long as the carabiners are able to touch in the middle it wouldn't cause rope twisting. Ideally they come together at <90 deg, otherwise you would have strength reduction and rotational force on the bolts but since they're glue ins and everything looks pretty beefy, it wouldn't matter much. |

|

|

Jim Day wrote: This is not true. This setup would definitely twist if left as is even though they can touch. |

|

|

Alex Fletcher wrote: I'll try lowering as is and report back on rope twist. Thanks. |

|

|

J- Ru wrote: Yes, if you dropped to one quick link on each it would twist. But, if you leave it as is it will also probably twist. Solution: Add a chain link, or better yet a three-link piece of chain, into the system between each quick link. Do this for both bolts. In the future, it is my opinion that all else being equal (meaning you're not restricted by existing bolt locations or limited anchor placement options), vertically staggered anchors for single pitch routes are far superior for many reasons. |

|

|

Alex Fletcher wrote: Rope twisting happens when there's distance between two anchors which are loaded. The greater the distance and sharper the bend between points, the more twisting occurs. So if the points come together when loaded, the rope wont twist, even if it's greater than 90deg Watch this video at time 30:00 |

|

|

Jim Day wrote: This is partly true and partly false. It is true that if the anchor points don’t come together (touch) there will likely be twisting. But just because they are touching doesn’t mean the rope will not twist. The path the rope takes coming up from the belayer, likely through protection, and then back down to the climber as they lower, can cause twists even when the two points of the anchor are touching. This can also be exacerbated if the way the rings/carabiners/mussy hooks are extended from the bolts forces them to twist away from one another when they’re pulled together by the weighted rope. The video above (relevant part is the last two minutes) is not incorrect but shows only two configurations (widely spaced rings vs a single ring lower off point) which are very exaggerated to illustrate the principle. However there are other more insidious factors that can result in twisted ropes (even when the anchor points meet together as one). |

Continue with onX Maps

Continue with onX Maps Sign in with Facebook

Sign in with Facebook