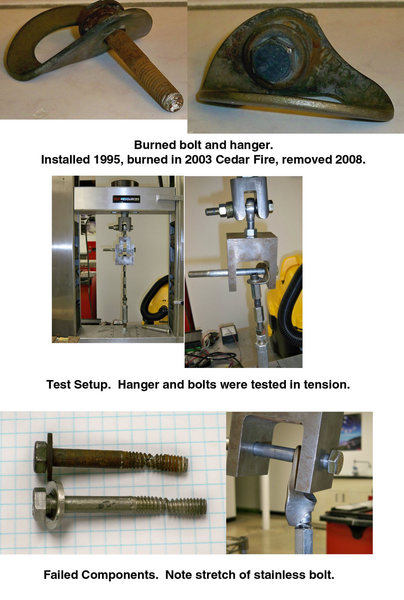

Burned out bolts

|

|

Ever wonder what happens to bolts after a forest fire? San Diego is known for fast and hot fires. The fire to end all fires occurred in 2003 and was devistating. One crag (Poway Crag) got hit hard and due to habitat restoration climbing went silent. Now we are faced with a crag coming back onto the scene but many of the bolts were severely burned. The fire was hot enough to affect the rock quality in areas. I ran into melted glass near my house in a burned zone. |

|

|

Wow, thanks for taking the time to experiment and post on an interesting topic! |

|

|

Very cool and Thanks! |

|

|

Glad to share. The test machine is driven by an electric motor of some sort. It can pull to 10K lbs. I pulled the bolts at .02"/minute and the hanger at .04"/minute. That took way too long to break the stuff since it stretches a bit. Next time I'll go faster. We have it at work and it is hooked up to a computer so you can play with the data in excel. The displacement is measured at the cross head so some of the stretch measured is the rest of the test setup. |

|

|

PS |

|

|

that is really cool... thank you. |

|

|

Sam Lightner, Jr. wrote:that is really cool... thank you. I generally don't worry about the strngth of the bolts that are relatively new, but I do wrry about quality control of every bolt...Does that make sense? In other words, I think that our gear has a lot of overkill built into it. OUr climbing gear is generally tested. However, our bolts are not. So the big question is "How many bolts in a box of 1000 are defective?" I ask this cus I know they sometimes are. I placed a hilti bolt, their standard, about 12 years ago and the head broke off. It was probably my 2000th bolt to have placed, so I knew not to over torque it. The thing broke with minimal pressure,s o I think it was just badly made. This why I wonder how often our bolts are bad when straight out of the box.I would consider Sam a "Master of boltology". It would be an interesting subject, who has placed the most bolts in the most types of rock in the most areas?. He might get it. |

|

|

Thanks Hank... I think it is a dubious distinction that I might fit that bill. However, in 1998 ALex C. and I started adding things up and I paled in comparison. We figured Alex had spent between 19 and 20 k on bolts in the 1990's. |

|

|

mschlocker wrote:Glad to share. The test machine is driven by an electric motor of some sort.Thanks! I just hadn't ever heard of that brand of machine and was curious what its deal was. Every now and then I cruise industrial surplus auction sites looking to pick up something similar for cheap, but no luck so far so I'm stuck with my homebrew pull tester. It'll do 10k with logging every 1/1000 second, but no displacement measurement. :-( mschlocker wrote:Check my personal page, I broke a dyneema sling as well. There are some forum posts on that too.Cool, I'll take a look for them. mschlocker wrote:PS Sure, go ahead and post a link on the "other" site. They need some help to catch up with the quality of MP.com.No joke.... The signal:noise ratio in The Lab section is much, much better than the rest of the site (since its highly and actively moderated), so if you haven't taken a look in a while it might be worth a visit. I kinda started taking it over about a year ago when I was looking for somewhere to put all my test results, and since they put me in charge a couple months ago I've been working on making it a good resource for testing and technical type information and discussion without all the typical RC crap. As for the rest of the site, well, I don't go there much. ;-) Oh, on an unrelated note since your doing testing might mean you're amused by engineering geekery.... I just put together a competition over on RC for homemade camming devices and there's a big announcement on the front page if you're curious. Trango is sponsoring it and the entry deadline is the end of February. -a. |

Continue with onX Maps

Continue with onX Maps Continue with Facebook

Continue with Facebook