Bolts Bolts Bolts

|

|

I'm tired of all the silly topics on MP, how about something different for a change... |

|

|

When you get a good system and rhythm going, Glue Ins don't take that much longer than a mechanical bolt. Certainly not twice as long. |

|

|

rawl powers 5 piece are sweet and seem to be kind of the standard in the west but suck for drilling on lead because they usually take two hands to place. |

|

|

good thread. |

|

|

bus driver wrote:rawl powers 5 piece are sweet and seem to be kind of the standard in the west but suck for drilling on lead because they usually take two hands to place. glue ins are sweet with stronger longer lasting potential and many have a shape that you could thread a rope through if you are pooching. But they take longer to set up so you have to wait some time before sending your new route. make sure you blow the hell out of the hole. dust and sugar lining the hole could kill the pullout strength. stud bolts are sweet because they are easy to place one handed and if you f up the hole depth you can still get a strong placement with what is in the rock. You can also see how long these bolts are by the letter stamped on end so you know how much is in the rock when you clip one.Depends on the glue you use. Mine is full strength in 35 min at 75deg. If you use studs you need to take the time to drill the hole the correct depth. Poor form to under drill and leave a long shaft sticking out. I typically OVERDRILL mine (not hand drilling mind you) so they can be pounded flush and patched if need be. I use 316SS or 304SS so hopefully that day is a LONG LONG way off. I've read about recent progress with core drilling the the wedges for removal so it may not even come to that. With 316SS it'll be a while... |

|

|

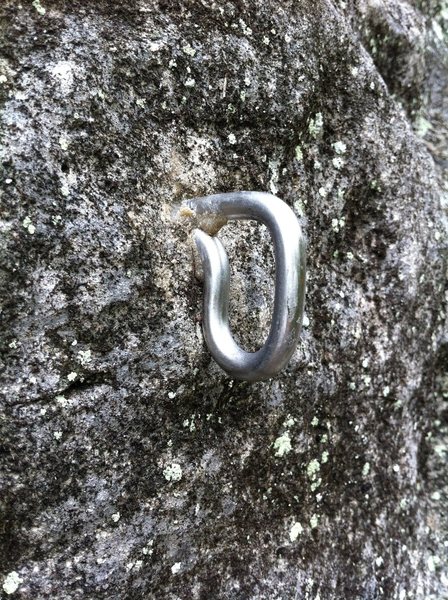

Are they those twisted rings from bolt-products. I bought a heap of them and they are awesome, no having to countersink the ring. |

|

|

What do you guys know about the removal or replacement of glue-ins? The appear to be exceedingly difficult to deal with. It is not as if you can pull the bolt and drill a new hole. Do you chop it at the surface and patch? |

|

|

Alex Whitman wrote:What do you guys know about the removal or replacement of glue-ins? The appear to be exceedingly difficult to deal with. It is not as if you can pull the bolt and drill a new hole.My understanding is that with the Bolt Products bolts you can do just that: basically "unscrew" the bolt then drill it out the glue so you can reuse the same hole. Honestly though, a properly placed SS glue in should be good for 50 years. |

|

|

johnL wrote:I've used and placed Jim Titt's bolts and think that they are the best product out there. I don't think they are quite as removable as he claims though. When it's time to replace them it'll be due to corrosion in a sea environment. They'll probably break when you try to unscrew them. As long as you are proactive and replace them early, they rule. I'm guessing 10 years for the ones in Bermuda. They'd probably outlast the epoxy inland.It is regrettably so that they are harder to remove than we first thought. At the time we were using a pure epoxy which softened with heat (and relatively low temperatures at that) and we could heat the bolt enough to get to unscrew. With polyester we could also heat it enough that it caught fire and broke down (exciting on a rope!). However the more common vinylesters and epoxy acrylates used these days don´t respond too well. Vinylester has better fire resistance and is used in fire sensitive applications and most building codes call for this these days for structural work, epoxyacrylate usually has a fire retardent added for the same reason. Core-drilling is the best at the moment for most bolts including wedge bolts but still is slow and a hassle, it works well in an area with easy access and lots of routes all together when it´s worth getting organised with a decent power supply, water etc but ideal would be if we could get some SDS core drills made that would work with standard drills and without water cooling. I found a company willing to make some prototypes but they aren´t exactly cheap, I´ve applied for some funding for this so might get somewhere on this in the winter. They will leave a rather large hole though which is another issue! Lifespan of stainless glue-ins is another issue which isn´t really ever going to be resolved, some places they are 40 years old and look like new, other places they look like hell after 10 years. I can get a definitive answer on stainless life depending on the grade from the manufacturers but only if I provide a full analysis of the air, rock, run-off water and climate which no climber is ever going to provide or afford. Getting a definitive answer on glue life from the manufacturers is also like talking to a politician, best you ever get is "up to 20/50 years" depending on who you talk to, one problem being that most of the glues haven´t been around long enough to know how they deteriorate in the conditions we use them since they are tested for construction purposes. |

|

|

This post violated Rule #1. It has been removed by Mountain Project.

|

|

|

Allen Corneau wrote: My understanding is that with the Bolt Products bolts you can do just that: basically "unscrew" the bolt then drill it out the glue so you can reuse the same hole. Honestly though, a properly placed SS glue in should be good for 50 years.In Texas I'm thinking more like 100 for 304SS and even more for my 316SS. That's assuming they don't have other factors like rock fall or thoughtless lowering wear kill them first... Time will tell |

|

|

|

|

|

Can anyone comment on experiences using Fixe Triplex 3-piece vs Powers 5-piece with respect to ease of installing and replacing? The Triplex design strikes me as clean and simple, but I have heard mention of spinners on install in both sandstone and granite even when care was taken to properly blow out and clean. I think the Powers 5-piece designs are nearly impossible to screw up on install assuming all things equal, but probably a good bit more work to get out. |

|

|

bus driver wrote:stud bolts are sweet because they are easy to place one handed and if you f up the hole depth you can still get a strong placement with what is in the rock. You can also see how long these bolts are by the letter stamped on end so you know how much is in the rock when you clip one.I'm able to place the expansion bolts on lead with one hand, but it's definitely a pain in the ass on the steep stuff. I'd like to give the stud bolts a go. |

|

|

Joseph P. Crotty wrote:Can anyone comment on experiences using Fixe Triplex 3-piece vs Powers 5-piece with respect to ease of installing and replacing?See here and here. The short version is that the Fixe is only (easily) removable in temporary installations with the sleeve flange above the hanger. With the sleeve flange above the hanger it is possible for repeated loadings to pull the sleeve out of the hole if the nut is loose. |

|

|

Despite having clipped thousands of them over the years and despite a good amount of curiosity about these things, I have never actually taken the time to experiment with bolt placing. I have always wondered: how long does it actually take to hand-drill a modern 3/8" bolt in various types of rock? How much easier & more efficient does it get if you're placing your thousandth hand-drilled bolt vs. your first? |

|

|

Peter Franzen wrote:Despite having clipped thousands of them over the years and despite a good amount of curiosity about these things, I have never actually taken the time to experiment with bolt placing. I have always wondered: how long does it actually take to hand-drill a modern 3/8" bolt in various types of rock? How much easier & more efficient does it get if you're placing your thousandth hand-drilled bolt vs. your first? Obviously it depends on a number of factors, but can anyone give me some basic stats for granite vs. limestone. vs. sandstone, etc?I recently hand drilled 7 bolts on a new sport route I put up in Western Colorado. I drilled 3/8”X2 1/4" in granite. The first bolt took me 10min the last bolt took be 30min. It takes a lot out of you. |

|

|

I am planing on puting up some routes on a new wall and am wonering if I can hand place them, use my standard cordless drill, or if I need to throw down some serious coin for that fancy climbing hammer drill that is on the market. |

|

|

ED-

Though this feature is not important to the top down installer. Edit: One handed meaning the bolt sits IN the hole, and you can let go to grab your hammer. 5 piece require (usually) a hand to steady the bolt during the first few strikes. Fear of the thing just coming undone is ever-present. |

|

|

Not quite sure what you mean by your comment. Here in the Potrero we don't have to worry about moisture and freezing and thawing etc so plated works fine and stainless is not necessary. |

|

|

why lay out all those bolts like that and not paint em? |

Continue with onX Maps

Continue with onX Maps Continue with Facebook

Continue with Facebook