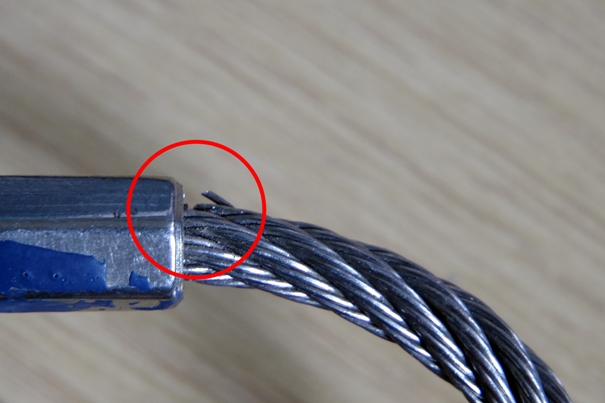

bent BD Camalot X4

|

|

Hey people,

bent cam X4 |

|

|

yes, it did ... :) - it was a very little fall as I was practically not above the piece ... |

|

|

I don't think you need to retire that piece. I would just bend it back. |

|

|

Ive pointed out before that the X4s have a longer metal stem head and a bit stiffer wire than some other cams and this could cause kinks at head ;) |

|

|

I've had issues with gear in the past and have always contacted the manufacture. They were always beyond helpful. They would create a return authorization, then inspect the gear in question. To point of safety testing it to failure and sending me a replacement. In my opinion the cam is structurally compromised. It may not fail the next 100 times or it may fail the very next time. Obviously, it is your choice on what to do. But contacting the manufacture would be my first priority. This also gives documented (if through email) proof that they said "nah, go take 50 falls on it, it's fine" or "no retire it and send it to us". I also think the company should know how their gear is doing in the field. Remember the gri gri recall? It was in part due to customers giving feedback. You really should contact BD, this could be an X4 issue or a fluke. Either way you took the time to post on here, how much harder would it be to send them an email? |

|

|

Mike Caracciolo wrote:I've had issues with gear in the past and have always contacted the manufacture. They were always beyond helpful. They would create a return authorization, then inspect the gear in question. To point of safety testing it to failure and sending me a replacement. In my opinion the cam is structurally compromised. It may not fail the next 100 times or it may fail the very next time. Obviously, it is your choice on what to do. But contacting the manufacture would be my first priority. This also gives documented (if through email) proof that they said "nah, go take 50 falls on it, it's fine" or "no retire it and send it to us". I also think the company should know how their gear is doing in the field. Remember the gri gri recall? It was in part due to customers giving feedback. You really should contact BD, this could be an X4 issue or a fluke. Either way you took the time to post on here, how much harder would it be to send them an email?+1 really good advice. Send it back - they'll look at it for you, if it's ok you'll get it back. If it's not, you might get a freebie. |

|

|

it looks like it is in pretty bad shape. i definitely don't agree with just bending it back. that is just asking for strands to start breaking, and once the first strand breaks it usually goes downhill pretty quickly. |

|

|

Thanks everyone for your opinions. I essentially had the same idea as Matt - but also understand that there is the possibility that the wire has been stressed too much. Looking up the information bearbreeder posted I will follow the suggestion of Mike and send it back to BD. |

|

|

Please let us (or at least me) know what happens. My entire rack is bd. I'd like to be assured I'm climbing on quality gear that is 100% backed by its maker. |

|

|

It's fine. |

|

|

Repeated bending and kinking of wire leads to metal fatigue. Is your life worth the $60-$70 required to get a new cam or do you have the equipment available to inspect your cam for microscopic cracks in the metal after bending the cam back to its original shape? |

|

|

folks |

|

|

Frankly, looking at the kink point it seems pretty obvious the placement was fairly shallow allowing the cable to kink in that spot. Loading the cable further back should not result in that kink |

|

|

Holy cow. Again, it's fine. Try to place it more in the direction of fall next time. Until then, bend it straight and climb on. |

|

|

limpingcrab wrote:Do some research, invisible breaks and microfractures etc. are a myth.Actually they are not, and I have seen them occur under a scanning electron microscope. Microfractures are BS, but cracks that are not visible to the eye most certainly exist, especially in aluminum. It's called fatigue. Under standard use, this is not something that concerns us. However, under conditions of repeated cycle loading, aluminum has a tendency to crack from fatigue. Typically, the crack starts at the portion of the device that is under greatest stress (as measured in PSI). On a micro level, at the section of the device under the greatest amount of stress, the crack typically starts at some form of abnormality in the surface of the device. It is standard for small scratches and dings to exist on a finished product because of the manufacturing process (they don’t exactly polish carabiners with 4000 grit sandpaper), and fatigue cracks typically start in one of the scratches or dings at the location under greatest stress. Anyway, once the crack starts it continues to propagate under additional load cycles until the product fails. This condition is well-known and well-studied, especially in the aviation industry. I have seen aluminum pulleys and carabiners fail from fatigue when used in slacklining, so under abnormal and extreme conditions cracks that are not visible to the eye can and do occur. Aluminum is especially susceptible to fatigue. In fact, aluminum has no fatigue resistance value (my term), which means ANY load no matter how small can technically induce fatigue. The load only determines how many cycles are required for the material to fail. Steel is also susceptible to fatigue, but to a much less degree than aluminum, and most alloys do have fatigue resistance values (typically 10% of breaking strength) in which any load below the fatigue resistance value will not induce fatigue, regardless of how many cycles the material is subjected to. Another method of failure, more relevant to the topic at hand, is yielding failure by which material that is stretched past its elastic limit (AKA yield strength) changes in shape permanently (albeit not necessarily visibly). Fatigue in AL: |

|

|

Let me rephrase. Materials can of course have stress fractures and problems that are invisible to the naked eye. At the same time I've never heard of any case where this can caused a climbing accident and I know of many cases where dropped gear has been tested and still retains it's strength. |

|

|

limpingcrab wrote:Let me rephrase. Materials can of course have stress fractures and problems that are invisible to the naked eye. At the same time I've never heard of any case where this can caused a climbing accident and I know of many cases where dropped gear has been tested and still retains it's strength. I should add that I'm no materials engineer so I'm pretty much talking out of my ass. I just did a lot of reading and research about this back when I thought buying used gear was a death wish. What I learned just encouraged me to buy used gear with a visual inspection.And would that cam pass your visual inspection criteria for buying used gear? |

|

|

I think supporting statements witch SEM pictures should be the standard on MP. |

|

|

This is some ideas from someone that would have the same questions if I ended up with that cam... |

|

|

Zappatista wrote:Is anyone's life really worth $60 or $70?I'll eat a 70 dollar bill and sh1t in your mouth |

|

|

"And would that cam pass your visual inspection criteria for buying used gear?" |

Continue with onX Maps

Continue with onX Maps Continue with Facebook

Continue with Facebook