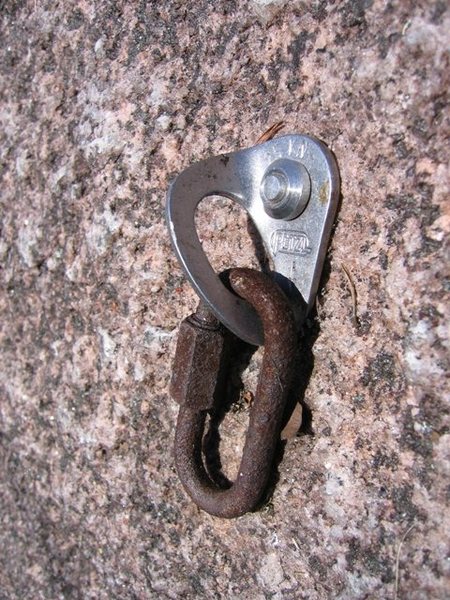

Zinc plated va stainless steel, anchors chains and quick links

|

|

Question for route developers and people with knowledge. Are hangers and bolts mostly zinc plated? And if they are how important is it for attaching non-zinc plated (stainless steel) quick links to them and using SS vs zinc plated chains. This is in regards to galvanic corrosion |

|

|

Jan Tarculas wrote:Question for route developers and people with knowledge. Are hangers and bolts mostly zinc plated? And if they are how important is it for attaching non-zinc plated (stainless steel) quick links to them and using SS vs zinc plated chains. This is in regards to galvanic corrosionHangers are almost always stainless steel, bolts used to be mostly plated but for the past 10 or so years have moved to being mostly stainless as well. A stainless quick link on a plated hanger or a plated quick link on a stainless hanger is not a problem at all in 99% of environments including southern California where it appears you are from. |

|

|

Hangers and bolts are a mixed bag of whoever buys whatever. I'd like to think most folks are using all stainless...or they should at least consider it. I wish plated hardware would go the way of the dodo... |

|

|

OP - spend some time on the Fixe website and you will learn all you need to know about metals. It's still very easy to buy plated steel bolts AND hangers, but there's no reason to use them anywhere any more, except that the route developer is a cheapskate who cares little for the long term safety of his route. |

|

|

I guess my question is, is it ok adding stainless steel fixe draws to zinc plated chains/quick link to a SS ring attached to the anchors |

|

|

It's worth noting that the "galvanic corrosion" caused by mixing metals effects one metal at the expense of the other. That's in fact how zinc plating works - the zinc is slowly sacrificed to protect the steel underneath. Eventually the plating is consumed and you have the raw steel, which then corrodes. In the case of mixing plated and stainless components in an anchor, it's the plated ones that will suffer. The most important component to protect is the bolt shaft itself, which is exposed to the most corrosive environment - the inside of the bolt hole. If the bolt and hanger are stainless, then as kennoyce says, it's probably fine in most dry-ish climbing areas. Any metallurgists out there know the actual galvanic potential between 304 stainless and zinc and/or grade 5 carbon steel? |

|

|

We gave up on the zinc plated a long time ago. We put in stainless exclusively. We didn't want to be responsible for someone getting hurt, especially considering the weather in the Adirondaks. When you think about the effort you put into a new line, what's a few dollars anyway? |

|

|

I think the reason why many people are concerned about rusting and galvanic corrosion is that not all plated hardware is created equally. There is some really good plated hardware such as the grade 5 and grade 8 carbon steel bolts that Powers uses in it's "5-piece" bolts. Then there is the really crap stuff you see with many wedge bolts and quick links. |

|

|

thanks for the info... |

|

|

frank minunni wrote:We gave up on the zinc plated a long time ago. We put in stainless exclusively. We didn't want to be responsible for someone getting hurt, especially considering the weather in the Adirondaks. When you think about the effort you put into a new line, what's a few dollars anyway?Anyone feel like changing the bolts on Eat Yourself a Pie ? |

|

|

Sorry. I don't live there anymore. |

|

|

A factoid re. quicklinks - the "safe working load" typically is 1/5th of the ultimate strength, so even the Homely Depot links are plenty strong enough. I know some climbers steer clear of them b/c they don't come from a reputable climbing company or carry a UIAA seal, but they're good enough for me. Use 'em in pairs if you want and put your fears aside. |

|

|

I was pretty disappointed to listen to the Enormocast on "the Choss Wranglers" - knucklehead developers down in the Roaring Fork Valley. "Can't justify say a...200-250 percent increase in price to develop a crag just because someone wants stainless - it's just not economical". I've lost my confidence in going to places like these where these guys are bolting/retro bolting - Rifle included. |

|

|

Jan Tarculas wrote:thanks for the info... p.s. I've been told 3/8 is the way to go for chains/quick links. My next question is what is an acceptable working load for a quick link that is use to attach chains to an anchor? I've seen at home have 2,200 lbs and other same size quick links at 3,600 lbs. Local developer mentioned he uses towing rated quick links at 5,000 lbsDepends on what the SWL factor is. The industry standard is 5:1 for non-life-critical applications, although some companies use 4:1. If the SWL factor is 5:1, then 2,000 lbs equates to a BS of 11,000 lbf, which is more than fine. Even if the SWL factor was only 4:1, it would still be stronger than any 3/8" bolt at 2,200 lbf SWL. Pretty much any reputable 3/8" SS quicklink is going to be stronger than most 1/2" bolts. |

|

|

climbing.com/climber/built-… topical, worth reading

|

|

|

Noah Yetter wrote:http://www.climbing.com/climber/built-to-last/ topical, worth readingYep. On important point from it... "Class 3 anchors will have “moderate” corrosion resistance. There will be no tests for SCC. Anchors in this class should be suitable for the bulk of climbing areas that have no special corrosion concerns, and it will be the minimum level of corrosion resistance recommended for outdoor climbing. Since this standard is being generated in Europe, it seems very likely that anchors in this category will have to show corrosion resistance equal to 304, and possibly 316 stainless. If so, this requirement is sure to cause some controversy in the U.S. " They have come out with 316 stainless for class 3 anchors -- saying that 304 stainless are not appropriate for outdoor anchors at all. (And, of course, carbon-steel, zinc-plated/galvanized, etc are, also, not appropriate.) |

|

|

We need to wrap our heads around a higher standard for hardware. It's coming. The fact is, very soon, you will be considered a rogue bolter if you are using plated hardware, even in the desert. Certainly, already, any European equipper would look sideways at your work. I've certainly placed my share of plated stuff, and made even worse hardware decisions before our state of knowledge got to where it is now, and I understand the under-funded developer mentality as well as anyone alive. But if you pry off a block in Indian Creek or an arid limestone crag in Nevada, you'll find damp dirt behind it. The inside of a bolt hole is the same. A long-lasting anchor in rock outdoors simply needs to be stainless. The more remote your crag, the more important it is to get it right the first time, because no climbing coalition is going to be following along behind you re-equipping your route, ever. 30 years is not that long. |

|

|

J Achey wrote:We need to wrap our heads around a higher standard for hardware. It's coming. The fact is, very soon, you will be considered a rogue bolter if you are using plated hardware, even in the desert. Certainly, already, any European equipper would look sideways at your work. I've certainly placed my share of plated stuff, and made even worse hardware decisions before our state of knowledge got to where it is now, and I understand the under-funded developer mentality as well as anyone alive.Agreed. We've pushed the topic so much here in the Portland area that now the climbers/developers are beginning to understand (and even expect now) that SS is the only reasonable choice, and almost all the developers have quit using plated as of this year. We've been pushing the education and reasons, and its starting to take effect. Now to get through to the Smith Rock developers... SS wedges work well in hard rock, as you're saying. But I think SS glue in bolts are the way to go, with either the Jim Titt bolt, or the ClimbTech Wave bolt being the prefered bolt. No need to countersink, they hold themselves in to the tune of 6-8kn without glue, and are pretty easy to install, and will last much longer than any SS sleeve or wedge bolt. And the cost is pretty cheap, with both bolts coming in at less than $6 a bolt, without bulk pricing. |

|

|

Even 316 SS can corrode inside the bolt hole in a surprisingly short period depending on the environment. Titanium glue-ins titanclimbing.com/Titan%20C… are around $13 each, but should last more than twice as long (50 years, allegedly). Still a tough cost to swallow without outside financial support. |

|

|

Noah Yetter wrote:Even 316 SS can corrode inside the bolt hole in a surprisingly short period depending on the environment. Titanium glue-ins titanclimbing.com/Titan%20C… are around $13 each, but should last more than twice as long (50 years, allegedly). Still a tough cost to swallow without outside financial support.It's far more than 50 years for SS in most environments. I've pulled 15 year old SS bolts out, and there has been NO sign of rust or corrosion whatsoever on them. I believe its reasonable to assume that SS bolts can last over 100 years in most places. Ti bolts certainly will last even longer. |

|

|

Micah Klesick wrote: I believe its reasonable to assume that SS bolts can last over 100 years in most places.I dont think that they will. Some will, but the problem is that some will not. Corrosion is an extremely localized mechanism. I have pulled bolts off routes and tested them to find the first bolt failed at 2kN, the 2nd failed at 35kN, the 3rd at 39kN and the 4th at 4kN. They were all the same bolt, same hanger, installed at the same time by the same person. So while most stainless bolts may last 100 years, random bolts here and there will not. Then the problem becomes that if you cannot trust a random bolt here and there, and you dont know which bolts can be trusted and which cannot because the corrosion is occurring in the hole, then you need to replace them all. The entire area is limited by the lifespan of the weakest bolt, sorta speak, unless you can be confident no corrosion is occurring in the hole, which you could never be if the bolt was 100 years old. |

Continue with onX Maps

Continue with onX Maps Continue with Facebook

Continue with Facebook