What's your gear placement success rate?

|

|

Fallen on gear many times. Fortunately not on poor placements, except once when a nut shattered the rock. Not the rock or the gears fault, mine for picking questionable rock. Still, that being said, if I had the choice to place a marginal piece or none at all I would take the marginal one. I carried all that junk up there, why not use it. It might not hold granted, but if I dont place it at all I guarantee it wont hold. I love the idea of keeping two pieces between you and the hospital / or the morgue. Two bomber ones are great, but I will take the best I can find. And your point about "all these gear failures in accident reports", they are not gear failures. They are placement failures. No where does Black Diamond or anyone else say they their gear will never come out, only that it is rated to X-strength. Most of these folks crying over gear failing need to realize that. This sport is not an exact science. |

|

|

If the choice was between mediocre gear and no gear at all, I'd go with the mediocre gear too. But I try to make sure that if I ever put myself in that position, I'm very confident I'm not going to fall. For me this means 3 or 4 grades below my onsight ability. My general rule is if I think there even a remote chance of falling, I want bomber gear a safe distance below. Personally I'm not ok with taking chances, although I'm guessing some people on this forum have a higher tolerance for risk than me. |

|

|

Yesterday I took a 15 footer onto a BD #6 stopper with less-than-optimal contact area and it held. I had to funkness the stopper to get it out, but I'm glad it held because I was looking at a 30+ footer if it pulled. I ended up bailing off the climb because I had too much adrenaline pumping through my body to do anything difficult. |

|

|

Totally agree. |

|

|

Free climbing, I've only ripped 1 cam ever. It was a borrowed purple c3. Turns out it was broken before we borrowed it. That's the reason it failed. I've fallen well over 200 times on gear, sometimes on terrible gear. I climb harder on gear than bolts because I trust what I place and I'm better at cracks. |

|

|

I would put my suscess rate at about 99%. Most of the time I can judge if a piece is going to pop or not. maybe 1 out of one hundred placements that I would judge to be solid acctually pops out. Alway from rope movement after I have a few pieces after it. |

|

|

I have taken more falls then I can remember. I have only had one piece pull out, and it was a marginal placement in low quality rock. I have fallen many times on smaller gear blue/green alien, small offset nuts etc. Sometimes I am suprised at how well the small offset nuts hold in marginal placements. That said, if I foresee myself making a runout, I will place 2 pieces 99% of the time especially if I am near the ground, or a ledge. I have had small nuts wiggle out a few times if they are not extended enough, but I am confident they would have held the fall, if I was climbing directly above them. |

|

|

New trad leader here - had my first big fall on gear on a .5 C4. It was slightly undercammed, but I figured it was ok. It held admirably and was a big confidence booster! |

|

|

polloloco wrote:New trad leader here - had my first big fall on gear on a .5 C4. It was slightly undercammed, but I figured it was ok. It held admirably and was a big confidence booster!yer gonna die. |

|

|

I've never pulled my top piece in a fall. I have had several nuts and at least one cam below the top piece, all of which I thought were marginal, pop with outward pull from a fall. |

|

|

Every piece I've ever placed has pulled, either from me falling on it or just climbing above it and listening to the sweet sound of metal bouncing down rock to the belayer. Nothing makes me feel so much like a climber, or so alive! Anybody want to climb around salt lake in the next month ;) |

|

|

James, do you have more info on the Metolius testing? One in 20 sounds alarmingly high when you are trusting your life in the gear. I wonder if this estimate factors in inexperienced leaders, or if it is based on good placements... |

|

|

I don't think it was the company doing the testing but rather one of their founders. I'll look for more info. Of course it's not the cams tha fail but rather user error or the rock. It does seem high but when you think of all the possibilities (rock quality, rope drag moving the cam, flaring crack) it's not out of the realm of possibility |

|

|

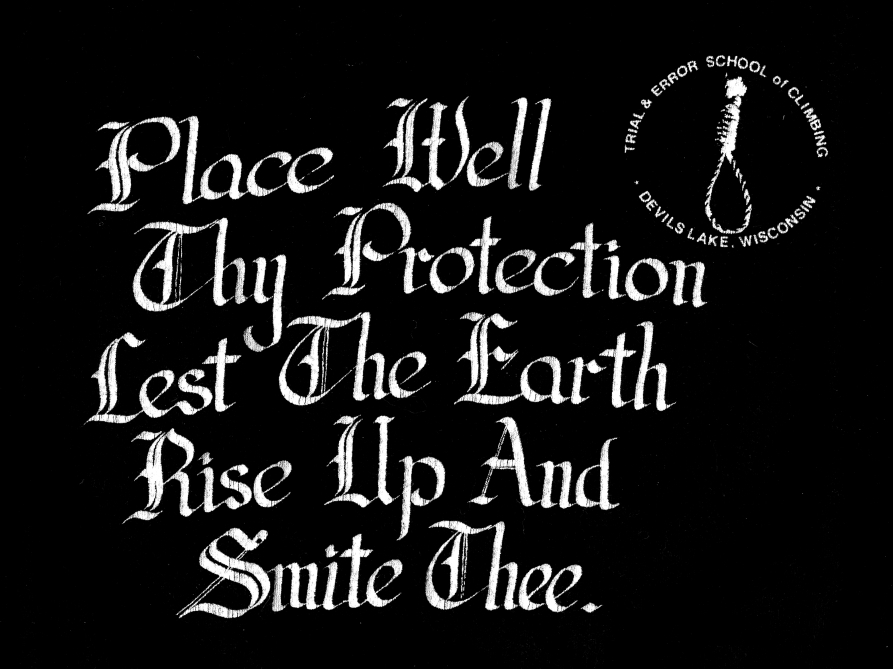

Better Beta

Cam placement rules As the founder and head designer of Metolius, Doug Philips has spent an immense amount of time testing and improving cams over the last twenty years. Here are some tips on cam safety based on his vast experience. Doug Phillips 1. No matter how good a placement looks, you can never be sure it will hold. During my tests, about one in twenty good-looking placements pulled out when loaded. The challenge is to figure out why the cam pulled, and what could have been done to prevent this from happening. To understand why cams fail, we classify pullouts into six basic categories: Lubricants (water, dirt, dust, moss, ice) Poor rock quality Cam movement (walking, misaligned) Poor placement Cam design Poor maintenance Lubricants Anything that gets between the aluminum cam lobe and the solid rock wall can act as a lubricant reducing the friction. Water is an obvious lubricant as is dirt or fine dust. A dirty seeping crack with a thin layer of moss can cause an otherwise good placement to consistently pull out. Poor rock quality There are three categories of rock to avoid: soft, smooth, and weak: Soft rock tends to crush under the load of a fall. The crushed particles act as a lubricant causing the cam to slip. After this type of failure, the cam lobes will often be coated with a thin film of pulverized rock. Smooth or polished rock will not allow the cams to grip. Smooth stone can be found in water polished cracks as well as glacier polished stone. It is very unnerving to watch a cam consistently pull out of a super smooth crack that would otherwise be a perfect placement. Weak or fractured rock will break, causing the cam to loose traction. When a cam pulls out of seemingly solid stone, I often find a small piece of fractured rock near one of the cam lobes. Occasionally a larger chunk of stone gets blown out of the crack due to an existing fracture or weakness in the rock. Cam movement Cams will move from the motion of a passing climber, rope action and impact from a fall. This movement can lead to pullout failures, as the cam is no longer positioned to hold a fall. To prevent this, place the cam so it has room to move and still remain in a good camming position. A long sling will reduce unwanted movement and allow you to fall on the next piece without putting any outward tension on the lower cam. Cam pullout failures commonly occur with a sharp outward or sideways pull rather than the downward pull you had intended. Poor placement Wide flares, bottoming cracks and irregular rock features make it difficult to get solid cam placements. Help optimize the security of a placement by maximizing cam-to-rock contact. Place good gear before and after difficult-to-protect sections. In my tests, I have occasionally been surprised by a bad looking placements that hold when drop tested. Most of the time however, if a cam looks bad, it will pull out. Cam Design The brand of cam makes a difference. Metolius cams are made with holding power as the primary design criteria. The main variables are cam angle, aluminum alloy, surface contact area, and cam alignment. Cam angle The cam angle we use is 13.25 degrees. This sacrifices range, but increases outward force, making the cams harder to pull out. Aluminum alloy Our aluminum alloy is 7075 for small and midrange cams and 6061 for larger sizes. The 7075 is stronger, maintaining cam shape under load in the small sizes. This is less of an issue in the large cams, so we switch to the lighter weight, less expensive, 6061. Surface contact area Surface contact area is important. More surface area will create more friction increasing the cam’s security. Also, more surface area spreads the load more, improving holding power in soft or weak stone. Our Fat Cams were designed with this in mind. Cam alignment Maximize holding power by lining up the cam lobes with the direction of pull. The original Friends did this by using a rigid stem. The Metolius cam’s relatively stiff “U” shaped body aligns the cam lobes with the direction of pull. Poor maintenance Like all technical equipment, cams require maintenance. This includes cleaning, lubrication, replacing old or worn slings and repairing frayed trigger wires. Be sure to retire worn out cams. 2. Place two good cams at critical spots Because one in 20 cams pull, reduce cam pullout by putting in a second good piece. This gives you a 99.75% chance that one placements will hold. Equalize them if possible. 3. Place the cam in as fully retracted a position as possible without getting it stuck. This is the green zone on our Range Finder system. Tight placements help to guard against the following types of pullout: Pullout due to cam movement Rope movement shifts cams. Long slings help, but you can increase security by placing the largest cam possible. If the cam moves to a wider crack section it will still have good contact with all four cams. Pullout due to poor rock quality If the rock on one side of the crack fails the cam lobes on that side will begin to slip. A cam with a tight placement (green zone) has a better chance of holding. If the rock on both sides of the crack fails, the lobes dig into the rock. The tighter the placement, the more the cam can expand before failure. Pullout due to lubrication When the cam pulls because of wet or dirty conditions it will move through several inches of crack before failure. If only one side of the crack is wet or dirty, the cam lobes on the wet side will tend to slip first. If the cam is in an open position the cams on the dry side will tip out and the placement will fail. In a tight placement the cams on the dry side will not tip out, greatly increasing the chance the placement will hold. I’ve observed a tight cam placement jamming just below the original placement. ;) |

|

|

Has anyone touched upon the idea that even if a piece rips, if there's another just below it, does the ripped piece not act as a shock absorber? |

|

|

Some very good points from Doug Phillips. Thanks BB for posting up. |

|

|

David Coley wrote:Some very good points from Doug Phillips. Thanks BB for posting up. A few comments: > Surface contact area is important. More surface area will create more friction increasing the cam’s security. Is this true? I thought I learnt at school the under loads the surface area didn't matter, as a larger area just reduced the pounds per square inch? > Cam alignment. Maximize holding power by lining up the cam lobes with the direction of pull. The original Friends did this by using a rigid stem. The Metolius cam’s relatively stiff “U” shaped body aligns the cam lobes with the direction of pull. Not sure I understood this. Most cams have an inch of stem which is rigid. Why would making it stiff beyond this make any difference? > Place two good cams at critical spots Because one in 20 cams pull, reduce cam pullout by putting in a second good piece. This gives you a 99.75% chance that one placements will hold. Equalize them if possible. The 99.75% (from 100*(1/20 * 1/20) seems unlikely to be true. It assumes the events are unrelated. The second cam will be in similar rock and placed by the same person. Also it assumes both placements are equally good. Presumably the first cam would have taken the best placement? Still good to place two cams! Just think the % might be a lot lower. I also thought the point about cam movement of the lower cam due to loading of the upper cam was very good. I will now make sure that lower cam is on a longer sling. One thing that I have been taking into account of late (after learning about it on MP) is that in a vertical crack the angle of pull is likely to be closer to the rock than the cam points in. This means the cam wants to rotate a little. As the cam lobes nearest the front of the crack can't slide downwards (as this is why a cam holds), the rear lobes must travel upwards to achieve the rotation. This means they are not helping keep the cam in the crack at this moment. Now, most of us kind of think the rear lobes are the most important ones, and are less worried about the front ones. I now put a bit more effort into getting the front lobes just right.hey david more surface area reduces the chance of of the rock breaking apart .. as to friction who knows im sure some math wiz will chime in about that .... when this was written there werent many truly flexible cams on the market, the main ones being the aliens ... even the "flexible" ones werent much better than todays camalots (not that flexible) years ago this was also said by BD... they found that unless the stem was somewhat stiff the holding power was less ... however with their new flexible X4s all this is now hushed up =P Not only do we have tests to show that it (the ‘stiffness’ of the stem) is not a problem, but we have tests that show too much flexibility is a problem in certain placements. Think about how cams work in a perfect placement: you pull straight down on the cams, that force is converted to a rotational force on the cams, and the surface of the cams push against the rock surface. Now place a highly flexible cabled cam in a vertical bottoming crack (the stem is sticking out horizontally). Should be good right? Think again about how the cams need to work. Pull straight down on this placement and you’ll notice a large component of the downward force is acting parallel to the cam surfaces. This is not how the cam is designed to work. The cams will not push against the rock surface without a force perpendicular to the cams plane of movement. In short, it stops camming and acts like a nut placement. You need some torque on the placement to convert the parallel load to more of an outward one that can act on the cams. This torque is provided by the stiffness of the cable, or the length of the shank of head terminal, or some combination of both. In testing, the high flexible cables did not generate the torque necessary to hold the falls and the units slid sideways out of the placement at very low loads. We even made C3s proto types out of softer cable, only to watch them fail our bottoming crack test because of this issue. the % of 2 cams holding is lower than mistah phillips suggests when improperly placed as a system an improperly placed second piece can increase the chance of the top piece pulling, and should the top piece fail can give a false sense of security ... Fall factor alone is not enough of a criterion on its own to characterize the severity of a fall because it considers only the rope itself. It is better to think about the impact force because this is the force directly received by the climber during a fall. - Petzl ive havent seen too many multi piece failures ... but one which i did see resulted in a hand sized camalot pulling in what should have been a bomber placement because of lack of extension on a roof (i know the placements on that climb) and the climber shattered both ankles i would guess that many of these multi piece pulling falls involve lack of extension and a lack of understanding of how gear behaves as a system heres an example ... the gear placements should be pretty bomber and straight forward on this climb, ive since done it myself ... youtube.com/watch?v=vqEbB6z… however you can see the issue with the lack of extension in slow mo ... in this case the "backup" piece didnt do anything as it rotates out with the pull due to lack of extension cam pointed mostly downwards cam pointed sharply outwards due to drag as climber weights the top piece cam pointed straight downwards after top piece pulls, right before it pulls |

|

|

|

|

|

Almost certain that the cams in that failure on Ruby's were too small. |

|

|

Probably the gear failing and him decking was due to the belayer sitting down. |

Continue with onX Maps

Continue with onX Maps Continue with Facebook

Continue with Facebook