|

|

20 kN

·

Sep 18, 2015

·

Unknown Hometown

· Joined Feb 2009

· Points: 1,346

·

Sep 18, 2015

·

Unknown Hometown

· Joined Feb 2009

· Points: 1,346

Harald Swen wrote:Fixe/Techrock finally posted an reply several days ago: techrock.es/en/news/stress-… That's a pretty lame reply. Numerous things they said are outright incorrect and the tone of the announcement is a bit unprofessional in that it seems like they are trying to take responsibility but at the same time avoiding responsibility and trying to shift the blame to outside influences.

|

|

|

WarthogARJ

·

Sep 19, 2015

·

Unknown Hometown

· Joined Nov 2013

· Points: 45

Hi Harald,

Thanks for input.

I'm not defending or attacking Fixe.

They HAVE had a least one failure with chain-related products, and they did acknowledge it, and are co-operating into investigating it.

The failure analysis as done by a 3rd party metallurgical company in Spain: it wasn't done in house.

You are correct, it hasn't been given complete public distribution, but these sorts of reports are not written for the general public, and are not always so easy to understand. But I can ask them if they all release it for those who would like to read it.

They also say that they have not finished their investigation, and as far as I'm aware, they haven't said that there WILL be or will NOT be a recall. Hard to know either ay until they get a better feel for what happened.

But as far as safety is concerned, they have tried to spread the news: they are not trying to cover it up.

And they DO say if you fin any more cracked chains or links, please tell them, or us: the UIAA. That would really help figure out what's happened.

And you are 100% right: it's a welded product: which makes things more complex (the steel composition and material properties change in the welded affected areas).

I'm not personally convinced that it is a SCC failure, but I'd need to see some more analysis to confirm either way. We are asking them for that, and I believe it might already have been on their list of things to do.

The UIAA's current position is that we don't favour the use of 304 in applications where you need corrosion resistance. We believe that 316 is superior for genera corrosion resistance and pitting resistance. It more than makes up for the difference in INSTALLED cost of 316 vest 304.

The cost differential of about 30% in bulk lots of material is greatly reduced after you look at the total cost of making an anchor: machining, inspection/QA, packaging, shipping etc. I bet it's less than 10% by time you're done. Then if you look at installation, even if you use a "slave labour" concept and expect the bolter to work for free, that further dilutes the difference. And if you cost their time at minimum wage ($15/hour in USA) then the percent difference basically disappears.

In terms of ABSOLUTE difference (and not percent), well yes there is some. But how much mass in an anchor??? You're talking PENNIES difference due to the difference in martial costs!!

If you were using TONNES of material to build a bridge, or refinery then OK: it makes a difference. But to a few anchors???

Hah.

The cost difference that YOU see is more due to importers not having much 316 product because you don't ASK for it.

So it's a self inflicted problem of higher price.

Sure if you buy thousands of anchors it adds up. But THEN you should be looking at the big picture: of the higher corrosion resistance of 316.

In Europe it is EASY to get 316 anchors, and hard to get 304. They've already understood these things in the construction industry.

For some reason I don't really understand, the USA construction industry still uses 304. Well, I DO understand it, but i don't want to get into it here.

But what the Big Brother construction guys do greatly affects our costs and availability.

Thanks for correcting my DAV numbers...:-}

The DAV is VERY good at getting members.

They offer a great deal.

Alan Jarvis

UIAA Safety Commission

|

|

|

bearbreeder

·

Sep 19, 2015

·

Unknown Hometown

· Joined Mar 2009

· Points: 3,065

So is 316 needed for urban outside climbing walls in germany (not exactly a tropical paradise)?

In squamish im willing to bet most ss is 304 ... Im fact theres tons of non ss hardware out here

Has there been these type of issues with other manufacturers links in non tropical non maritime areas?

;)

|

|

|

Jim Titt

·

Sep 19, 2015

·

Germany

· Joined Nov 2009

· Points: 490

bearbreeder wrote:So is 316 needed for urban outside climbing walls in germany (not exactly a tropical paradise)? In squamish im willing to bet most ss is 304 ... Im fact theres tons of non ss hardware out here Has there been these type of issues with other manufacturers links in non tropical non maritime areas? ;) Well the first rule of preventing corrosion in stainless is keep it clean, parts which a regularly washed don´t really suffer but a chainset under a roof overhang will always be more prone. Change "urban" to "industrial environment" and you are getting nearer the typical German climbing wall built in a converted industrial plant downwind from an interesting variety of chemical works, steel works, coal fired power stations and who knows what. My nearest wall is built in and outside of a disused sewage treatment tower so God only knows what runs off the concrete and over the anchors, at the wall I generally use the anchors are straight through aluminium cladding into the concrete structure below and there are plenty more examples out there. The price difference for 304 to 316 depends on the stock diameter but over the range I use (8,10 & 12mm) it averages at 21% more. For finished products we simply add 5% across the board rather than calculate each individually as the labour/material proportion varies. I´d drop 304 altogether since it´s just a hassle having two lots of stock but we still sell about 30% in 304 and we are in a competitive market so the customer gets to choose, if the proportion drops much more I´ll probably get rid of it altogether. Most places 304 works just fine. The DAV´s "active" involvement isn´t suprising, someone failed in their duty ensure the equipment installed was suitable for the application and to routinely inspect it allowing it to deteriorate to the extent it failed, as it was a DAV wall.......

|

|

|

WarthogARJ

·

Sep 19, 2015

·

Unknown Hometown

· Joined Nov 2013

· Points: 45

Hi BearBreeder,

Dang, that name reminds me of the joke of the hunter, the grizzly bear, and the fat lady.

Probably cannot tell it on this forum...:-}

OK, this is going to be a long email, but it sums up our current noughts on anchors.

And please don't take it as an attack on you, Mr. BearBreeder.

I'm sure you're a fine fellow, and your Mother loves you....:-}

But it's a good time to answer this sort of comment.

This issue of (not) using 304 is ALWAYS stirred up by examples like you just made.

Someone comes up an example of a place where 304 has worked fine.

For last X number of years.

Great.

Happy for them there.

But what about the places it did NOT work.

And funny enough, those ones don't get mentioned as much...hmmmm.

But if you look at the bigger picture, think of ALL the climbing areas globally that are not at risk from SCC, but DO need some corrosion resistance.

So either 304 or 316.

Or to reduce the scope a bit, consider just continental North America.

And think of trying to get a system going where you look at the costs of bolting over a lot of them. For a known lifetime: say 50 years.

Let's be even simpler, take the costs of bolting for just 100 areas.

We're not talking just one area, where you MIGHT get the anchor selection right, due to local knowledge, or luck, and 304 works fine.

Because out of that 99 OTHER areas for SURE there will be at LEAST one cliff, if not 10 or 20 where 304 does NOT work well.

And it fails before 50 years.

And you DO need the extra corrosion resistance of 316.

And for that area where 304 DOES seem to work for 50 years, does it have to work for ALL the anchors? Like say there are 100 routes, each with 10 bolts. That's 1,000 anchors. If any one fails, will THAT be a problem?

And also, how do YOU know what happens with the climate over the next 50 years?

Just because it seems to have been OK for 304 for the past 10, or even 20, what about the next 30???

There's what, say 1,000's of (bolted) climbing areas in the continental North American region??

More?

You give me your estimate.

Doesn't matter though exactly, is more than 100 and less than 1 million areas.

OK, so the aim is to install anchors that can last a DEFINITE and predictable working life.

If you screw up on just ONE area you might have injuries/death.

And conceivably if your unlucky, or Joe Climber is, just ONE failed bolt in the wrong place at the wrong time can be an issue.

If you get it wrong, you need to re-bolt.

The cost of revolting that eats into what you saved by using 304.

It doesn't take many cases where you didn't get your guesses right before you are LOSING money by trying to SAVE by using 304.

Ad 316 is a LOT better than 304 in terms of corrosion resistance.

And how long should they last?

Not, well "we hope it will last 10 years".

"Wouldn't it be nice for 20".

Etc etc.

But for a DEFINED working life.

Let's be engineers, and think like engineers that are putting up safety critical items.

Where if they fail, can cause serious injury, or at worse, death.

And even if not this, then REPLACING them is a huge hassle.

And also affects access: what land owner wants climbers being hurt by bad anchors?

Law suits, cleaning the blood up etc etc.

There is absolutely NO reason why we cannot achieve at LEAST a 50 year working life.

With a choice of 316 or of a SCC-resistant anchor.

It's already being done all over Europe.

In the construction industry.

MILLIONS if not several BILLON anchors.

Don't argue about this unless you do the homework.

Check the facts first.

Europe has 750 million people, and the construction industry does this.

LOTS of money involved, lots of buildings and other structures.

For safety critical anchors, they can achieve a 50 year life time, with existing off-the-shelf stuff.

Google EOTA, and their policies for anchors.

Do the math about the COST of bolting for 50 years: and don't even add in a cost of loss of life.

I compared several costs for 304/316 anchors compared to titanium.

Used installation costs, and several scenarios for labour cost: free, minimum wage ($15/hour) and $20/hour.

Do this analysis yourself, or I can send you my spreadsheet.

The point is that you need an anchor to last at LEAST 20 years before it STARTS to break-even with titanium: for a low cost glue-in anchor that costs $4. If you go up to $6, it jumps to 27 years.

Add in labour costs of an bolter, then at minimum wages it needs from 26 to 31 years to start to break even. With titanium.

A 304 5-piece expansion-type with anchor at $10.80 needs to last 41 years to break even!! With titanium.

And if you can use anchors that are cheaper than titanium, but still last 50 years, then the break-even is even LONGER. Doesn't make sense to use something that lasts a shot time and needs re-bolting.

But 304 will NOT last 50 years dependably across this spectrum of conditions. I'm not talking tropical, I'm talking continental North America. OK, inland Canada is the best place for 304 to last 50 years. Although not a lot of BC. Or Ontario.

And a layman will NOT be able to predict well enough when they need to use 316 instead. Even a specialist corrosion engineer will not be able to, without doing a study of actual conditions Which will cost money, and take time. And eat away the difference between 304 and 316.

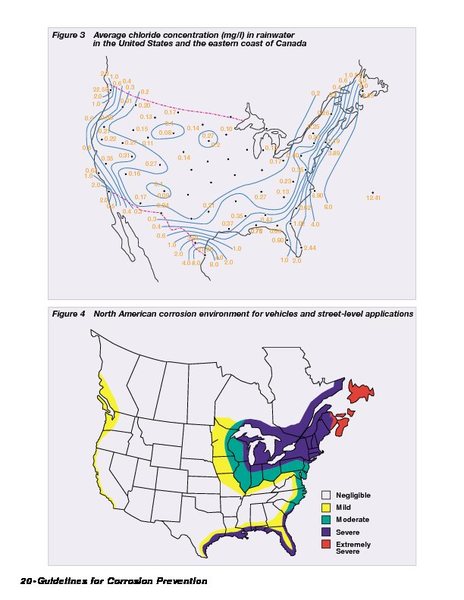

Look at the attached figures for salt contents: see how much they vary, and how far inland it goes. And the 2nd figure explains WHY. Salt is carried in aerosol form by the wind, up to 10's of km inland.

Arguably anywhere that is "negligible" could use 304, or perhaps galvanized for 50 years. But Mild-Moderate? It will vary between needing 304 and 316 to last 50 years, with local conditions affecting the results.

There is no magic cut-off temperature for where corrosion "starts". Or even where you can get SCC. Both are more a function of things like how often the area is washed by the rain, or the local RH.

And on a given cliff of say 1,000 anchors, over a 50 year period, how many are YOU as a climber willing to fail when YOU need them to take YOUR body weight, or in fact many times more your body weight WHEN (and not IF) you fall on it?? Are we playing Russian Roulette here? Well, yes we are. Up to now.

OK, on a specific cliff, with a long history of 304 being used successfully then you could make a decision to use it, with a small risk of being wrong. We're going to try to write that into the standard. In effect, to "grandfather" some areas. But you need either the exposure time, in decades, or else professional input.

The trouble is, the more classes you add, the more complexity, the more chances of messing things up.

Most of the issue of using 304 or 316 is money: sticker shock. The guys (and gals) who bolt often pay for the anchors themselves. And the bulk of climbers who depend on them are freeloaders: and don't pay anything. I bet 80% aren't even a member of a climbing federation.

It's not the bolters' fault: it's the freeloading general climbing public. If they paid towards the anchors then you could get what was NEEDED. Donate to the Access Fund or ASCA. How much? Well, how much did you pay for your pre-torn jeans? Designer sunglasses? Starbucks over the past 5 years? On-line porn?

If you climb on bolted routes you SHOULD look at paying in maybe $1,000 over the next 10 years. And that's CHEAP. If you climb a lot, you should pay more. I would say if you don't pay, you shouldn't argue about what's right or not. You haven't earned the right. Sorry for being blunt.

This has ALREADY been thought about in Europe in the much larger construction & building industry. THEY did the math, thought about, and decided 304 was not cost effective compared to 316. You cannot buy a 304 construction anchor in Europe. No market for it.

Nobody uses them. They use 316 or better.

Europeans are CLEVER about things like this. And ORGANIZED.

I'm not trying to attack Americans, but it's VERY difficult to get a change like this in the USA. There are literally THOUSANDS of standards bodies in the USA (for all sorts of things).

In Europe there is ONE central unifying body.

it's one reason why the USA is still metric. And why there is such a large spread in how things are done from state to state. It's no accident that Canada, with many other things similar IS metric, and is more organized for a lot of engineering issues.

Europe has 750 million people: they USED to be a real mix of affairs. Not any more. At least not for things like this.

Corrosive environment and salt in North America

Windborne salt as function of windspeed. Note that after it levels out, it STILL stays quite high a LONG way inland: 100's of km.

|

|

|

Alex Bury

·

Sep 19, 2015

·

Ojai, CA

· Joined Jun 2012

· Points: 2,376

All I can say is that I am very glad to not have installed any of these. I had thought about it previously, but where chains are needed I've opted for a quicklink connection to fascilitate replacement.

Still no word from Fixe?

|

|

|

WarthogARJ

·

Sep 19, 2015

·

Unknown Hometown

· Joined Nov 2013

· Points: 45

I'd be interested in responses, this is not yet set in concrete.

But please read it all thru carefully.

ideally print it out and read it.

Then do any Google you need to do.

Think about it.

And THEN reply.

There have been lots of very experienced materials engineers involved in EXACTLY these problems in construction. And the UIAA got input from some very knowledgeable materials engineers to confirm the general ideas here.

When you are thinking about it, pretend that you have the backing of a bolting fund that wants to have a working lifetime of 50 years. With a low risk of failure.

Even if you shoot low and use Three Sigma, that's 1 or 2 failures out of 1,000. Is that acceptable? What if they are crux bolts?? What if it's YOU, or your significant other, or your child climbing on the bad one and IT fails? Is that OK. Still "acceptable"?? Worth a pair of pre-torn jeans??

Sure you say, climbing is accepting risk. But is this risk NECESSARY? No. If you use the right anchors you can have MUCH better than 3 Sigma, for 50 years. For not outrageous amounts of money.

If you DO want more risk, then don't use bolts, go trad. Then at least YOU control the risk. Or free climb.....:-0

I'll post the report that Tomas Prosek (of the French Institute of Corrosion) and I did to explain the rationale. I'll put it on the UIAA website soon. And a few more things.

I'll announce it here. This forum, and in particular John Byrnes, have been very supportive of the ideas of increasing bolting safety.

|

|

|

bearbreeder

·

Sep 19, 2015

·

Unknown Hometown

· Joined Mar 2009

· Points: 3,065

ahhh ... but we arent talking about 50 years in fixe case ...

but 2-3 years or so ... theres quite a few of these fixe chains and rings out here

it would be nice to have something that lasts 50 years ... but to be blunt theres still a big gongshow about someone in squamish using homemade staples and saying its just fine, never mind getting everyone going to 316 SS i suspect

and in theory we live in a maritime raincoast environment here ... climbs that dont see many ascents a year will get mossed over in 5 years

youre absolutely correct about folks who rather spend money on that nice dead bird/patagucci jacket or after cragging beer, but not contribute to the the climbs ...

im guilty of that having let my membership lapse, time to renew ... though in my defense i should say i do carry a bag of goodies and replace worn/missing hardware out of my own pocket at the crag when im able

;)

|

|

|

WarthogARJ

·

Sep 19, 2015

·

Unknown Hometown

· Joined Nov 2013

· Points: 45

Hi Jim,

This is a reply related to your email.

You are one of the competent as well as experienced small end stainless steel fabricators. "Small end" as in you don't have a big staff (do you HAVE "staff" outside of your dog and kids??).

Like compared to Hilti, or or even the climbing manufacturers you are small.

But you have got expert input when you thought it was needed: I believe you said you'd used Graham Gedge's services before? I know him, very knowledgeable materials engineer/scientist.

I'd be VERY interested in a more exact breakdown of the cost differential between 304 and 316 anchors. I've already asked for an American firm to supply a more detailed costing: their claim was that 316 was much too expensive for them to use it for anchors. So I am calling their bluff.

I'm not buying 304/316 material in big volumes direct from the mills, or big suppliers, but my understanding was that in bulk quantities, the differential in rolled and flat product is around the 29%. So your price of 21% is bit lower than what I found, but same ball park.

However, my point was that that is NOT the difference in finished product.

Let's say you make 1,000 anchors a day.

You need to pay manufacture costs (labour, depreciation etc etc).

Packaging.

Inspection: assuming it is actually done.

I'm sure Jim does inspection, but I'm not 100% sure that everyone does unfortunately.

Shipping to suppliers.

Advertising (if done, even just cost web page).

Tax, insurance etc. etc. etc.

Add that up, plus your profit and THAT is your price to your retailers.

Accounting 101: should be basic for the forum people.

So if you sell an expansion anchor plus hanger at say $10 to your retailer, how much was the raw material cost?

Maybe $0.40??

How do I get that?

Well until Jim or the USA guys tell me a better value, you can buy 304 or 316 8mm round bar in China FOB at $2,000 per ton.

Minimum order 2 tons.

I'd argue if you are truly a player in the field, then you will be buying in bulk.

You will not be going through Honest Ed's Metal Supply and Donut Shop that buys their stock via 6 middlemen, each one adding their cut on top.

And an anchor, either glue-in (twisted or forged), or expansion c/w hanger are ALL around 100-120 grams.

So using a rough price of $2,000/ton, you get 19 to 24 CENTS per anchor.

Add on a bit for wastage.

Is still SMALL.

So a 304 anchor material cost was $0.40, and 316 was say $0.52 (lets be generous and round up to 30% price difference).

Let's do the math.

Say a 304 anchor (5 piece plus hanger) costs $10, and 316 cost is $10.12.

Which is 12 cents more.

Which is LESS than ONE percent.

Peanuts.

Actually HALF a peanut.

If you bought 15 anchors to bolt a route, the differential is 15 * $0.12 = THIRTY cents.

Peanuts.

If you buy enough for a route (say 15 anchors), it is 15 * $0.12 = $1.80

Not peanuts, but a peanut candy bar.

Or a SMALL Starbucks drink: maybe.

Without the cream and sprinkles.

Look, if any of you guys & gals want to bolt a route, and will name it something with Warthog in it (Dead Warthog, Glorious Warthog etc etc) then I will send you this differential in cash, gold coin or PayPal.

The extra Twelve cents per anchor.

Just knowing that I have helped make the world a slightly safer place, and spread the glorious Warthog name around gives me a warm fuzzy feeing.

If it's a LOT more routes, and they ALL have Warthog in the name I am still keen.

Like maybe even ALL the routes in the ENTIRE North America for one year.

I'm not sure if I COULD say No to people who named 10,000 routes with the name Warthog in all of them.

Dang.

I would not only get a warm fuzzy feeling, but I'd get so happy that well....I better not go further or else the Moderators will censor this.

When I get a more accurate material cost per anchor than my wild $0.40 guess, then I will update the post.

Like if Jim can tell us what it is for HIS anchors, then we can do it.

Or else the chaps who sell anchors in the US.

But do you see my point?

Anyone who tries to tell you that a 20-30% difference in material cost translates into a major difference in selling price should be selling the Brooklyn Bridge. Or ice to Eskimo's.

I CAN see one argument, if a US-based person tries to buy a 316 construction anchor, then it WILL be more.

But NOT because of it being 316 MATERIAL per se.

But because the big sellers of construction anchors get very little demand and import fewer quantities.

THAT is the reason.

It is NOT the material.

But many construction anchors are made in China.

And the SAME factory that makes 304 ones for the You Ess of Ay (USA) will be making 316 for Europe. Same machines, same people.

If you order enough, you can get a good price on either type.

With a low price difference I bet.

It will NOT be 20-30%.

If it is, you are being ripped off.

The UIAA might look into helping North American climbers source 316 anchors. I doubt we'd be financially involved: we don't have the manpower to look after it.

But we could get it going.

It's a safety issue, and if the suppliers cannot or will not do it, then we'll make it happen.

And I have a few contacts who could DEFINITELY do it.

Alan

The Warthog Route Maker

|

|

|

20 kN

·

Sep 20, 2015

·

Unknown Hometown

· Joined Feb 2009

· Points: 1,346

·

Sep 20, 2015

·

Unknown Hometown

· Joined Feb 2009

· Points: 1,346

WarthogARJ wrote: Even if you shoot low and use Three Sigma, that's 1 or 2 failures out of 1,000. Is that acceptable? What if they are crux bolts?? What if it's YOU, or your significant other, or your child climbing on the bad one and IT fails? Yes, it's acceptable because those 1 or 2 out of 1,000 are not complete equipment failures, they are failures to meet the 3-sigma rating. If the 3-sigma rating of a bolt is 25kN, a sample that falls outside of that range is still very likely going to hold 20kN or more. While that's lower than the rating, it's still almost twice the strength of a full size cam and more than adequate to catch any whipper anytime.

|

|

|

20 kN

·

Sep 20, 2015

·

Unknown Hometown

· Joined Feb 2009

· Points: 1,346

·

Sep 20, 2015

·

Unknown Hometown

· Joined Feb 2009

· Points: 1,346

WarthogARJ wrote:Hi Jim, This is a reply related to your email. You are one of the competent as well as experienced small end stainless steel fabricators. "Small end" as in you don't have a big staff (do you HAVE "staff" outside of your dog and kids??). Like compared to Hilti, or or even the climbing manufacturers you are small. But you have got expert input when you thought it was needed: I believe you said you'd used Graham Gedge's services before? I know him, very knowledgeable materials engineer/scientist. I'd be VERY interested in a more exact breakdown of the cost differential between 304 and 316 anchors. I've already asked for an American firm to supply a more detailed costing: their claim was that 316 was much too expensive for them to use it for anchors. So I am calling their bluff. I'm not buying 304/316 material in big volumes direct from the mills, or big suppliers, but my understanding was that in bulk quantities, the differential in rolled and flat product is around the 29%. So your price of 21% is bit lower than what I found, but same ball park. However, my point was that that is NOT the difference in finished product. Let's say you make 1,000 anchors a day. You need to pay manufacture costs (labour, depreciation etc etc). Packaging. Inspection: assuming it is actually done. I'm sure Jim does inspection, but I'm not 100% sure that everyone does unfortunately. Shipping to suppliers. Advertising (if done, even just cost web page). Tax, insurance etc. etc. etc. Add that up, plus your profit and THAT is your price to your retailers. Accounting 101: should be basic for the forum people. So if you sell an expansion anchor plus hanger at say $10 to your retailer, how much was the raw material cost? Maybe $0.40?? How do I get that? Well until Jim or the USA guys tell me a better value, you can buy 304 or 316 8mm round bar in China FOB at $2,000 per ton. Minimum order 2 tons. I'd argue if you are truly a player in the field, then you will be buying in bulk. You will not be going through Honest Ed's Metal Supply and Donut Shop that buys their stock via 6 middlemen, each one adding their cut on top. And an anchor, either glue-in (twisted or forged), or expansion c/w hanger are ALL around 100-120 grams. So using a rough price of $2,000/ton, you get 19 to 24 CENTS per anchor. Add on a bit for wastage. Is still SMALL. So a 304 anchor material cost was $0.40, and 316 was say $0.52 (lets be generous and round up to 30% price difference). Let's do the math. Say a 304 anchor (5 piece plus hanger) costs $10, and 316 cost is $10.12. Which is 12 cents more. Which is LESS than ONE percent. Peanuts. Actually HALF a peanut. If you bought 15 anchors to bolt a route, the differential is 15 * $0.12 = THIRTY cents. Peanuts. If you buy enough for a route (say 15 anchors), it is 15 * $0.12 = $1.80 Not peanuts, but a peanut candy bar. Or a SMALL Starbucks drink: maybe. Without the cream and sprinkles. Look, if any of you guys & gals want to bolt a route, and will name it something with Warthog in it (Dead Warthog, Glorious Warthog etc etc) then I will send you this differential in cash, gold coin or PayPal. The extra Twelve cents per anchor. Just knowing that I have helped make the world a slightly safer place, and spread the glorious Warthog name around gives me a warm fuzzy feeing. If it's a LOT more routes, and they ALL have Warthog in the name I am still keen. Like maybe even ALL the routes in the ENTIRE North America for one year. I'm not sure if I COULD say No to people who named 10,000 routes with the name Warthog in all of them. Dang. I would not only get a warm fuzzy feeling, but I'd get so happy that well....I better not go further or else the Moderators will censor this. When I get a more accurate material cost per anchor than my wild $0.40 guess, then I will update the post. Like if Jim can tell us what it is for HIS anchors, then we can do it. Or else the chaps who sell anchors in the US. But do you see my point? Anyone who tries to tell you that a 20-30% difference in material cost translates into a major difference in selling price should be selling the Brooklyn Bridge. Or ice to Eskimo's. I CAN see one argument, if a US-based person tries to buy a 316 construction anchor, then it WILL be more. But NOT because of it being 316 MATERIAL per se. But because the big sellers of construction anchors get very little demand and import fewer quantities. THAT is the reason. It is NOT the material. But many construction anchors are made in China. And the SAME factory that makes 304 ones for the You Ess of Ay (USA) will be making 316 for Europe. Same machines, same people. If you order enough, you can get a good price on either type. With a low price difference I bet. It will NOT be 20-30%. If it is, you are being ripped off. The UIAA might look into helping North American climbers source 316 anchors. I doubt we'd be financially involved: we don't have the manpower to look after it. But we could get it going. It's a safety issue, and if the suppliers cannot or will not do it, then we'll make it happen. And I have a few contacts who could DEFINITELY do it. Alan The Warthog Route Maker I am not sure China is exactly the go-to place to buy stuff that, if fails, results in someone's death. Their product typically blows. I have bought numerous stainless quicklinks and shackles made in China, and they were complete shit. Also, China is very literal in their manufacturing process. If you say you want two tons of 316, you're going to get exactly that. It wont be passivated, it wont be treated, it will just be raw stock. That wont work. You have to specifically tell them you want it passivated, and you have to tell them how, and if you want it treated to meet a specific strength requirement (e.g. A4-70), you have to specify that too. If you need a guarantee of workman quality and strict limits on the composition and treatment of the metal, you need to specify that as well, and you need to tell them exactly how you want all of that done. Once you do that, the price is going to go way up.

|

|

|

Jim Titt

·

Sep 20, 2015

·

Germany

· Joined Nov 2009

· Points: 490

The FOB price in China isn´t very relevant, it´s the price of a guaranteed quality material delivered to your works that matters.

Depending on what you are making and how material intensive it is then the grade makes a difference to the cost of manufacture, for me very little but for stamped or rolled products it´s considerable.

A price difference of 20 to 30% between 304 and 316 products is normal but can vary a lot more.

It´s "passivated" as in inert not "pacified" as in calmed down. It´s anyway a process you do after working the material as bending or welding sensitizes it, it automatically comes passive from the mill as it is annealed (unless you specifically ask for another condition).

|

|

|

Harald Swen

·

Sep 20, 2015

·

Oisterwijk

· Joined Apr 2010

· Points: 0

I know and I've talked to quite a few guys involved in new routing. Done some myself as well and do know quite a bit about it. And yes, most of those involved go for cheap. They are downright ignorant when it comes to material properties and figure 'it says inox, stainless or whatever' so it must be good. Then comes the bolting. Badly cleaned, loose rock not removed and glue-ins placed not deep enough. And yes, single bolt belays. Welcome to Germany, home to some to the shittiest bolting in Europe. I'm offering the best bolts money can buy for free, no strings attached. But nobody's interested. FFS, why invest your own money and do a shoddy job when, with minimal cost and slightly more effort, you can do a proper job that'll last for 50 years?!?

Bolts severely corroded in highly corrosive rock (after 2 years), 'why don't you use 316 of titanium?' Answer: 'I know what I'm doing.

In comes the new wall-bred generation who believe all protection to be safe and sound. Accidents waiting to happen. Access to lots of climbing areas in our area hasn't been secured. A serious accident or death will most likely lead to the area being closed. Why the stupidety? Why?

|

|

|

bearbreeder

·

Sep 20, 2015

·

Unknown Hometown

· Joined Mar 2009

· Points: 3,065

To be blunt again

We can call those who use 304 stainless steel all the god awful names in the book ... And blame em for causing accidents on unsuspecting newbie gym climbers who never learned how to evaluate fixed gear

But these evil developers are out there putting up routes or replacing old rivets, pitons and decades old homemade hangers with that evil deadly 304

Im not saying that there aint something better, or perhaps things can be done better ...

But i dont see too many other golks stepping up to the plate

Last month i had to replace several nuts and hangers that fell off ... Im gonna burn in hell for it as i used a plated steel nut/washer on a 304 SS hanger ... Because thats all i had on me, and i pay for everything i replace myself

On one of these climbs, the area sees alot of traffic and no one else bothered to carry out ever a wrench and a few goodies to replacthe missing hanger for a few weeks ...

Now you can criticize a lazy uncaring bum like me if you want, but then i suggest you go out and replace that gear yourself again

Perhaps folks are ignorant, set in their ways and dont want to spend extra money

But they are out there replacing old or missing gear, often out of their own pocket, while the rest of us are too lazy or dont care enough to do anything about it ...

But all us MPer care enough on da intrawebz to make a huge fuss

Would 316 SS have helped fixe here .... Note that the rest of the chain and ring which is 304 doesnt have any issues we know of ... Wasnt it the manually welded section that broke

;)

|

|

|

WarthogARJ

·

Sep 20, 2015

·

Unknown Hometown

· Joined Nov 2013

· Points: 45

Gents,

Let's split this into two parts.

It was initially about this specific failure.

(1) Failure:

The material was out of specification.

It was not 304: Carbon on high side, Chrome below spec. P above spec.

And it was 304, and not 304L.

You can google this, but you're better off with 304L (or 316L) for welding.

And with the material being out of 304 spec, the high C, low Cr ad high P means you are even WORSE off for welding sensitization of the HAZ.

Again, google is your friend here if you aren't up to speed on these terms.

But the bottom line is the ENTIRE chain was potentially susceptible to corrosion in the areas around the welds (the HAZ: Heat Affected Zone).

Re-welding made it even worse, but the other links might well fail prematurely too. But wait!! What is "pre-mature" if nobody says how long it is intended to last???

(2) I've explained why 304 is a poor choice for climbing anchors.

Anywhere.

From the standpoint of corrosion resistance as a function of additional cost.

Perhaps at moment you can see WHY it is used.

Combination of people not knowing this, and a hassle to get hold of 316(L).

But you CAN.

And 304 is not "evil", but someone who uses the wrong material in an area who KNOWS it's wrong IS evil.

But we don't YET have a good mechanism for classifying anchors as to their corrosion/SCC resistance.

Nor for locations.

We will soon have one.

And THEN, if people WANT to do the right thing they CAN.

If they don't, well, all we can do is chop bolts, give them a hard time, sue them if someone has an accident etc etc.

But now I wouldn't really blame anyone for using 304. In North America.

Because the whole SYSTEM is a bit messed up.

However in some cases, 304 IS acceptable.

But as I explained on a cost basis WHY use it???

As soon as enough people realize, demand will pick up for 316 and there's no excuse to use 304 over 316.

But in Europe if someone uses 304 for climbing anchors NOW they are an idiot. And close to being negligent.

Perhaps criminally negligent if there's an accident as a result of its lesser corrosion resistance: it is VERY well known that 304 is not a suitable material for anchors in outdoor locations in Europe.

I will stand as a witness pro bono except costs if anyone wants help if they are hurt by a 304 failure in Europe.

Alan

|

|

|

M Mobley

·

Sep 20, 2015

·

Bar Harbor, ME

· Joined Mar 2006

· Points: 911

bearbreeder wrote:To be blunt again We can call those who use 304 stainless steel all the god awful names in the book ... And blame em for causing accidents on unsuspecting newbie gym climbers who never learned how to evaluate fixed gear But these evil developers are out there putting up routes or replacing old rivets, pitons and decades old homemade hangers with that evil deadly 304 Im not saying that there aint something better, or perhaps things can be done better ... But i dont see too many other golks stepping up to the plate Last month i had to replace several nuts and hangers that fell off ... Im gonna burn in hell for it as i used a plated steel nut/washer on a 304 SS hanger ... Because thats all i had on me, and i pay for everything i replace myself On one of these climbs, the area sees alot of traffic and no one else bothered to carry out ever a wrench and a few goodies to replacthe missing hanger for a few weeks ... Now you can criticize a lazy uncaring bum like me if you want, but then i suggest you go out and replace that gear yourself again Perhaps folks are ignorant, set in their ways and dont want to spend extra money But they are out there replacing old or missing gear, often out of their own pocket, while the rest of us are too lazy or dont care enough to do anything about it ... But all us MPer care enough on da intrawebz to make a huge fuss Would 316 SS have helped fixe here .... Note that the rest of the chain and ring which is 304 doesnt have any issues we know of ... Wasnt it the manually welded section that broke ;) IMHO you may be an internet "expert" on just about everything but man o man are you out of your league in this conversation. Got any Petzl links you want to share?

|

|

|

bearbreeder

·

Sep 20, 2015

·

Unknown Hometown

· Joined Mar 2009

· Points: 3,065

T Roper wrote: IMHO you may be an internet "expert" on just about everything but man o man are you out of your league in this conversation. Got any Petzl links you want to share? The conversation is about fixe chains breaking If you havent noticed thise chains are in quite a few areas ... And at the very least the links at the start of this thread will let folks know what to look for As to the rest .... In euroland those bums may do things differently but i bet the vast majority of SS here is 304 .... Most retailers here dont sell 316 i believe Now one can call folks ignorant and idiots ... But then the vast majority of folks who waste their time and money replacing old rusty chains or missing hangers are probably such If one wants positive change you wont get it by calling other folks names on da intrawebs, especially those who volunteer their time and money ... You get it by engaging them and the retailers that sell the gear As to the legal side .... Thats a VERY slippery slope for one to go down "testifying" against someone who put in 304 ... Climbing is to a large degree at yr own risk , just because there are bolts on a climb or someone replaced a 30 year old worn and rusted chain with a 304 or even hardware store quicklinks, doesnt mean fresh out of the gym climbers can expect it to be totally "safe" If such an environment where folks sue folks over hardware, especially keeping in mind that the FA may not have intended anyone else to climb it after them especially on longer out of thr way routes ... Then to puy it simply that will be death of folks volunteering their time and efforts We could go on about how a refusal to replace manky pegs, not adding anchors at the top, having runnouts on climbs or even chopping a bolt would be a liable action Once you move away from "climb at your own risk and insure your own safety at all times" ... To a "it must be safe or ill sue you" mentality ... That wil be the death of climbing as many of us know it ;)

|

|

|

climber pat

·

Sep 20, 2015

·

Las Cruces NM

· Joined Feb 2006

· Points: 286

I am confused about much of the arguments above.

Why choose 50 years as the design life of an anchor? Why not 25 years or 100 years? I would like to understand the reasoning.

It seems to me that if we could get poeple to quit using wedge bolts and change to some more easily removed bolt then replacing bolts/hangers and anchors would be much less effort and resonable to do routinely. Of course people are using wedge bolts because they are even cheaper.

Why propose 316 SS over titanium if truely design life and cost is the important criteria?

The cost differential at the retail level is quite easy to look up at fixe's web page.

1/2 x 4.75 PS $3.25 powers bolt hanger $2.00 ring anchor $8.70

1/2 x 4.75 SS 304 $9.95 powers bolt hanger $3.00 ring anchor $14.00

12mm x 90 mm SS 316 $12.95 wedge bolt hanger $6.35 ring anchor $21.50

Titanium glue in bolts seem to be about $12-$15 plus $1.00 per glue(?).

Keith Titanium seems to selling a titanium wedge bolt/hanger for about $30.

This is a pretty significant price increase for better materials. I imagine that the cost to machine the better materials is the reason for much of the price difference rather than the price of the raw materials. It appears the titanium glue in is cheaper than 316SS and more corrosion resistant(?).

|

|

|

M Sprague

·

Sep 20, 2015

·

New England

· Joined Nov 2006

· Points: 5,090

·

Sep 20, 2015

·

New England

· Joined Nov 2006

· Points: 5,090

WarthogARJ wrote:..I will stand as a witness pro bono except costs if anyone wants help if they are hurt by a 304 failure in Europe. Alan This brings up a serious down side to having "Official Specs" to what an individual can use for climbing anchors (as opposed to manufacturers). It shouldn't be, but with assholes with that attitude, rather than serving as an education tool, it could kill individual route equipping and everything could end up having to be through organizations with permit processes to avoid the danger of route setters being sued. I am all for encouraging people to use good hardware, but new routing could end up like little league if we don't watch out. Peer pressure and education and pride should be the motivators, not fear of being sued if you haven't used 3/4" X 12" titanium glue-ins with two safety inspectors looking over your shoulder while installing them (with monthly safety checks by a certified engineer thereafter of course)

|

|

|

M Sprague

·

Sep 20, 2015

·

New England

· Joined Nov 2006

· Points: 5,090

·

Sep 20, 2015

·

New England

· Joined Nov 2006

· Points: 5,090

Slightly off topic, but how do the titanium glue-ins wear compared to the 316 SS ones? Are there issues if steel quicklinks are hung off them? any other factors to consider beyond corrosion resistance besides the initial price?

|

Continue with onX Maps

Continue with onX Maps Continue with Facebook

Continue with Facebook