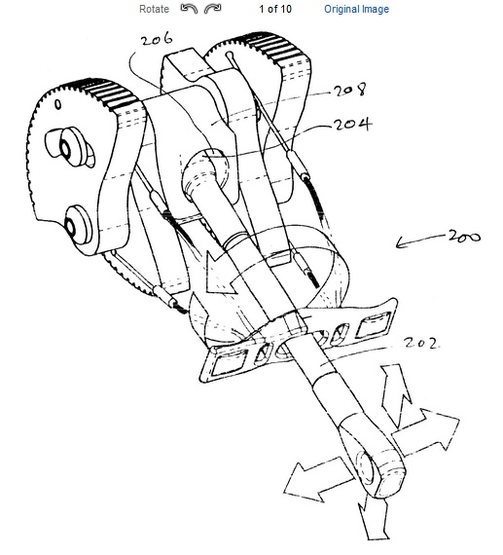

CAD model of a BD camalot number 1

|

|

Wiki wrong!? You've just shattered my belief in all that is true in this world! :-D |

|

|

Wisdom? Hardly. As I mentioned, most of it is buried over on ST. I just happen to have spent an inordinate amount of time digging for such things. :) |

|

|

Dug through my notes, and that patent I mentioned that allows relative movement between the stem and head is US6679466 and was apparently it was assigned to Wild Country. Looks like the patent might have lapsed due to nonpayment of the fee. |

|

|

Sweet patent! |

|

|

The spring forces the cup at the bottom of the stem onto the locator. Making the default position straight out. Not as good a design as a flexible cable. |

|

|

Depends on the strength of the spring, no? |

|

|

No. |

|

|

As luck would have it, you /can't/ buy a cam with that kind of head. So no need to worry. :) |

|

|

I know they don't exist and I'm not worried. ☺ |

|

|

Me? None of the above. But IMO that one comes closest to addressing the root cause of cam walking, which is the net torque on the head due to pulling on the stem. |

|

|

Aric Datesman wrote: IMO that one comes closest to addressing the root cause of cam walking, which is the net torque on the head due to pulling on the stem.What? Seriously! Why would you think that design is better than a flexible cable? |

|

|

Because this design can be done with that same flexible cable and this head termination results in a shorter lever arm than a traditional brazed/staged head termination (which is decidedly inflexible). On top of that, with a weak locating spring the cable would have even more ability to move in relation to the head. |

|

|

can you share your preferred solution? I get what you are saying about less leverage on the head than a brazed wire but neither really solve the issue of walking in my opinion. I agree the first swing at the hydro cam wasn't that great but could you expand upon why you don't believe the abstract idea of a pre-loaded cam is a solution to walking? |

|

|

if you want a cam that doesnt "walk" much ... go buy totems (not the basics) ... |

|

|

Kyle Cobbler wrote:... could you expand upon why you don't believe the abstract idea of a pre-loaded cam is a solution to walking?Well, it's because I see increasing spring pressure as a hack rather than a solution. A proper solution would eliminate the possibility of walking; not simply make it more difficult. [quote]"can you share your preferred solution?"[/quote] Afraid not, as it's part of a design I'm looking to make commercially. That said, Bearbreeder is right... Totems are a good example. No stem, so nothing to torque on the head. Another good example is the Maxcam mod we discussed here on MP a long while back that converted it to a stemless single axle cam with a textile piece pulling on the levers on the center lobes. |

|

|

I agree with every Aric has to say here. As well as making engineering sense, he has also had plenty of experience in this area. |

|

|

patto wrote: On a related topic how common do people find that a walking cam is an issue or of concern. Personally I RARELY find it an issue where I climb. Maybe 1 in 50 placements or 1 in 100. Normally this is an issue with larger sizes.if you extend em is not as much a concern ... however there have been several accidents where multiple pieces in good solid squamish granite has pulled ... while we cant say the the placement themselves werent and issue, many of those climbs i know the placements by heart and the placements are not complicated what likely happened IMO is that folks didnt extend their pieces enough and when they fell the upward/outward pull of the rope shifted the cams into a poor position in fact theres an accident or two in MP where this may well have been the case, including the infamous "i blew out 3 X4s and decked" incident when you see someone climbing moderates, how do you tell if they are newer climbers or older experienced folks who dont climb as hard, other than the grey hair and pot bellies? the older experienced folks will usually extend many of their pieces ... the newer folks often wont understanding how the protection works as a system is whats hard ... placing the individual pieces, at least in good squamish granite, is fairly simple for the most part ;) |

|

|

patto wrote:.... As well as making engineering sense, he has also had plenty of experience in this area.I dunno about that last bit, Patto, but I will admit to being an engineering geek that dove headlong into climbing gear design the moment my wife forbade me from making my own climbing gear. :) So, Kyle.... Seems you've caught me at just the right moment in life, and with a quite unexpected baby coming any day now (adoption, been waiting a year and a half, got matched a week ago) I'm looking to clear my plate of designs that went nowhere but were interesting mechanically. Six pages in I'm guessing we've lost most everyone who isn't mega-geeky, so here you go... First up: I pitched the design to Trango ~2008 as a way around BD's patent on double axle cams. In a nutshell, it's a single axle design that not only mimics the relative motion of the lobes in a dual axle design, but also provides the greater expansion ratio of the dual axle design in a single axle package. Another way to put it is that it's the unholy child begotten from the cross of a cam and a Ballnut. Slot Cams Did I mention the small one had an expansion ratio of 1.7:1 and large one 2.5:1? The math behind it isn't that hard, but takes some doing to get your head around it due to the center of rotation for the spiral that makes up the bulk of the expansion being several inches outside of the physical confines of the cam lobes. If you stare at the free body diagram for the loading of a cam the reason why this is possible will eventually become clear. Sadly the combination of spring issues and the BD patent expiring killed it. On a side note, this design was pretty much immune to walking, as the axle was free to move within the individual lobes. The two smaller ones were on my rack for a couple years and saw regular use (as well as passing a 10kN proof test). They worked well, but not as well as my current design. BTW, solving the spring issue for this design lead to an interesting tangent to get around CCH's patent on flat spiral springs.... a cam with no springs whatsoever. A dead end now that the CCH patent is expired, but fun to play with. Will post pics if I can find the prototype... |

Continue with onX Maps

Continue with onX Maps Continue with Facebook

Continue with Facebook