|

|

rocknice2

·

Mar 4, 2014

·

Montreal, QC

· Joined Nov 2006

· Points: 3,847

This came to light from another post called "Accident on Manic Crack in NM". I don't want to get into why Kerr's cams blew out of the crack. We have that thread for any of those comments. I do want to discuss if there may be a problem with the X4's.

So it's obvious from these pictures that the cam was loaded perpendicular to the fall line. It's not what we are supposed to do but the manner in which the cam popped out is of concern to me.

.3 x4

.3 x4

It appeared to me that as the cam bent over, the trigger may have released the lobes. I don't expect the cam to be full strength in this case but I do expect it to fail by way of broken cable, swage, solder or lobes...etc. Not self-clean out of a crack.

So I proceeded to make a little test jig. In a vise I squeezed a 5/8" plate between two thick knurled plates forming a bottoming crack. Then I placed the cams at the bottom of the 'crack' sticking straight out and jerked them [by hand] at a 90 degree angle down. Not scientific but I did get some interesting results.

X4 .3: I was able to make the trigger release the two upper cam lobes with a strong jerk. The bottom of the trigger rocked on the metal part where the cam and cable are crimped. The cam would rotate until lobes reengaged. Can't speak to whether the lobes would reengage in a real world scenario, this may be something to discuss. In a shallow crack there would be no chance what so ever!

Alien Green: I was not able to make the trigger release the lobes. The very flexible cable bent over more behind the trigger, so I wasn't able to rock the trigger enough to make it release the lobes but I came pretty close. I suspect a harder pull would indeed result in a self triggered lobe.

C3 Yellow: This cam did wonderfully! Looked weird as the double stem rotated to enable it to be pulled down but absolutely no sign of self triggering, not even close.

I stopped there because these are the only cams I own.

UPDATE March 14 2014:

After receiving and posting the email from BD there was a skeptic who posted "trust us we're the experts". Eluding that BD may know about the problem. I decided to revisit my my home made jig. As I said earlier this was not a lab controlled test but a test none the less.

So what I discovered was, I was at fault. When I jerked the cam/sling at 90deg my hand actually went beyond the 90* point to possibly a 120* angle. This time I tried to make sure not to go beyond 90* and the X4 cam did not self clean. I need to admit that originally I stated that I pull the cam down at 90* but in fact that was not entirely accurate. I placed it straight down and pulled horizontally. I said that I pulled down so not to make things confusing because the relevant thing is what angle the pull was made. Well as a result it was easy to bring my hand down and not control the angle of pull correctly.

I'm sorry I fucked up. Hope nobody sold their rack of X4's because of this. ;-)

UPDATE March 6 2014:

I emailed BD with concerns regarding this test I made to see what response I would get. This IS ONLY FOR MY TEST not for anything other than this test. After a few emails back and forth Kolin was very helpful and informative. He didn't bash my results but this was a indeed backyard test. That's why I wanted to see what the pros would say. Here's what they had to say:

" I can appreciate your non-scientific tests - and as you may or may not know - the amount of testing we do when developing a new climbing product would blow your mind. Of course all of our cams meet all CE requirements, but that is only the tip of the iceberg of what we consider the required testing prior to BD putting a piece of PPE on the market. Design teams of climbing engineers going over every detail - climbing on prototypes in our local Wasatch range as well as around the world. Tweaking the design, more prototypes, continued exhaustive lab testing, and then back outside for more taking forced-whippers. In the lab we perform static tests, dynamic tests, bottoming crack tests - both static and dynamic, cams in different kinds of rock, wet, icy - you name it. We have a book, literally… a book, of all the tests that our cams go through during the design and development phase, with associated internal Black Diamond requirements that we’ve created over the years. We also test all competitors cams to our internal BD standards to understand where the unofficial bar of acceptability is. You’d be amazed. The amount of time we spent on testing the X4s was monumental. We know typical use situations as well as imagine most conceivable mis-use and abuse scenarios as well. We design and test around the scenarios as best we can, acknowledging that every route, every rock, every placement and ultimately every loading scenario is different. One thing I always say around here, “you can break anything under the right circumstances”. And we’ve proven that time and time again.

We painstakingly work on our instructions so that climbers know how to use the products, and understand the limitations of the product. Only when that is done do we go to production. And then it’s an entirely different level of testing: from testing the incoming raw materials, to work-in-process tests during the manufacturing and assembly, to 100% finished good proof testing and finally finished goods statistical product destructive batch testing. (it never gets easier seeing perfectly good brand new product get tested to destruction). I can base that confidence having been a climber for 25 years, and have 25 years of mechanical engineering experience in a manufacturing environment with 12 years of heading up Black Diamond’s top-notch Quality Assurance Team. "

I sent back an email asking to be more clear as to the shallow bottoming crack and perpendicular load. This was the response:

" As far as the X4s go

once again - we test for pretty much everything

did we test for bottoming crack, shallow placement? - yup

did we make rating? Not even close

did we test every other cam on the market including our own? You betcha

did they get results much different than ours? - not really

Did we spend an astronomical amount of time tweaking the interface between the axle swage and the trigger wire ‘distal’ to fro to avoid the flex of the cable pulling on the trigger wires on what we consider a pretty crappy placement ? Yes

dd we specifically do our best to design the trigger wires to have a strength such that if you’re reefing on the trigger, they don’t break, but in the situation described above, they just might - allowing the cam to stay in the crack Yes

Do we warn that a bottoming crack placement is a crappy placement in the instructions? yes, a shallow bottoming crack placement is a crappy placement.

For sure sometimes you take what you can get

just like placing a 2kN microstopper if that’s all you can get in - but if you barely load that, the cable will snap

Climbers need to understand the limitations of their gear. Just because you can place it doesn’t mean it’s a good placement.

Once again - you can get anything to fail under the right circumstances.. "

I got permission to use his responses here.

|

|

|

csproul

·

Mar 4, 2014

·

Pittsboro...sort of, NC

· Joined Dec 2009

· Points: 330

Can you post some picture of your setup so that people can evaluate your test?

|

|

|

rocknice2

·

Mar 4, 2014

·

Montreal, QC

· Joined Nov 2006

· Points: 3,847

An interesting artical here

alpineexposures.com/pages/b…

Quote from a BD designer

"Not only do we have tests to show that it (the ‘stiffness’ of the stem) is not a problem, but we have tests that show too much flexibility is a problem in certain placements. Think about how cams work in a perfect placement: you pull straight down on the cams, that force is converted to a rotational force on the cams, and the surface of the cams push against the rock surface. Now place a highly flexible cabled cam in a vertical bottoming crack (the stem is sticking out horizontally). Should be good right? Think again about how the cams need to work. Pull straight down on this placement and you’ll notice a large component of the downward force is acting parallel to the cam surfaces. This is not how the cam is designed to work. The cams will not push against the rock surface without a force perpendicular to the cams plane of movement. In short, it stops camming and acts like a nut placement. You need some torque on the placement to convert the parallel load to more of an outward one that can act on the cams. This torque is provided by the stiffness of the cable, or the length of the shank of head terminal, or some combination of both. In testing, the high flexible cables did not generate the torque necessary to hold the falls and the units slid sideways out of the placement at very low loads. We even made C3s proto types out of softer cable, only to watch them fail our bottoming crack test because of this issue."

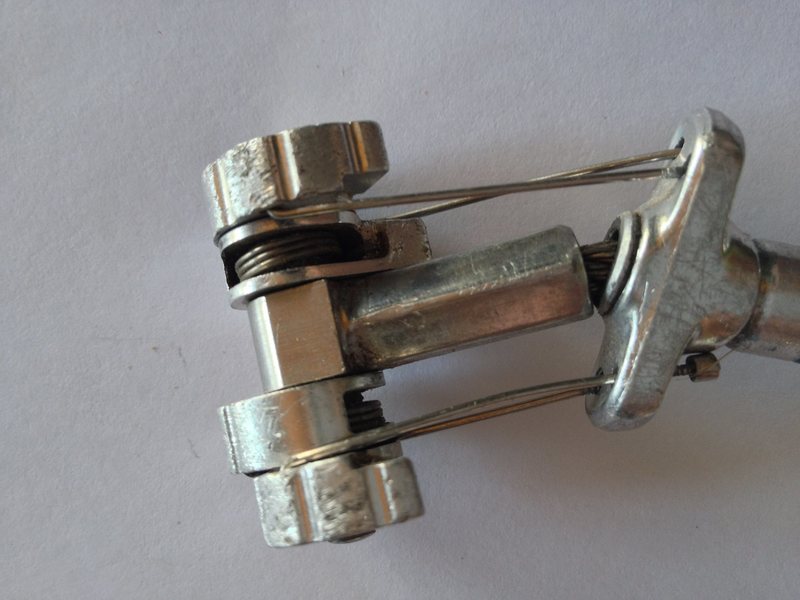

This is not my C3 but will illustrate how the double axle rotates.

![]()

|

|

|

rocknice2

·

Mar 4, 2014

·

Montreal, QC

· Joined Nov 2006

· Points: 3,847

csproul wrote:Can you post some picture of your setup so that people can evaluate your test? No I did it last week and took it down already bu I can make a drawing if it helps.

|

|

|

rocknice2

·

Mar 4, 2014

·

Montreal, QC

· Joined Nov 2006

· Points: 3,847

This is the best I can draw. Imagine the cam bottomed agaist the back plate.

jig

|

|

|

bearbreeder

·

Mar 4, 2014

·

Unknown Hometown

· Joined Mar 2009

· Points: 3,065

not that i doubt you .. but to make these claims i think you need to post videos for MPers

it shouldnt take too long ... just an iphone vid would be fine

;)

|

|

|

Larry S

·

Mar 4, 2014

·

Easton, PA

· Joined May 2010

· Points: 872

It looks like a similar failure mode that can occur with the smaller mastercams (though in practice no one seems to notice on the mastercams): If you bend the cable in just the right way, the "puller bar" moves away from the head, which pulls the wires, retracting the lobes of the cam.

In this case it looks like it can occur when the head is prevented from rotating in line with the fall by the geometry of the crack, causing a tight bend in the cable at the head in a direction parallel with the axle, retracting the lobes at one end of the axle. Exactly what happens at that point I can't say, the lobes may re-engage at some point when the head has rotated sufficiently - assuming the placement is deep enough.

On a small mastercams it happens when in a shallow placement if the cable is loaded over an edge: putting a tight bend in the cable just below the head perpendicular to the axle retracts one lobe from each end of the axle, followed by the cam falling out.

|

|

|

john strand

·

Mar 4, 2014

·

southern colo

· Joined May 2008

· Points: 1,640

i have an old Wild Country booklet that describes this situation pretty well,,I'll try to find it

|

|

|

Medic741

·

Mar 5, 2014

·

Des Moines, IA (WTF)

· Joined Apr 2012

· Points: 265

Huh. Makes me really want to sell the x4s I own...

|

|

|

Shelton Hatfield

·

Mar 5, 2014

·

Unknown Hometown

· Joined Apr 2011

· Points: 650

Medic741 wrote:Huh. Makes me really want to sell the x4s I own... I'd be interested in a .1 if you've got it. PM me

|

|

|

Hampton Uzzelle

·

Mar 5, 2014

·

Tucson, Arizona

· Joined Jul 2006

· Points: 5

It seems like that since the manic crack accident there have been several reports of small cams pulling from placements that seemed okay. It definitely looks like the kink in the stem pulled the trigger bar and disengaged the top pair of cams. I had not seen or heard of this problem with small cams before. I wonder if designing the trigger bar to float over the head of the unit where the cable is attached would not mitigate this problem. I know it would not address the lack of torque issue that BD observed with flexible stems, but it still seems like it would be an improvement to the design. The downside may be that the tigger wires would be more likely to get tweaked over time, but I'd prefer that to the cam self releasing.

|

|

|

Luc-514

·

Mar 5, 2014

·

Montreal, QC

· Joined Nov 2006

· Points: 12,536

·

Mar 5, 2014

·

Montreal, QC

· Joined Nov 2006

· Points: 12,536

I had a .2 x4 pull from a diagonal crack last summer, at a belay where I had 2 other bomber pieces, just under body weight.

First time I ever had a piece pull in 20 years if I ignore a #00 tcu in back of a flake ;o).

The sizing seemed pretty good, the only thing I could see would have been the trigger against the lip of the crack.

I plugged another cam next to the X4 and clipped it to the cordelette.

|

|

|

Will Cohen

·

Mar 5, 2014

·

Denver, Co

· Joined Dec 2012

· Points: 80

Isn't this one of the very reasons cams are supposed to be placed in line with the fall?

Is it fair to blame poor placements for gear failure?

|

|

|

rocknice2

·

Mar 5, 2014

·

Montreal, QC

· Joined Nov 2006

· Points: 3,847

I was always under the assumption that a cam place in a perpendicular position was a weaker placement. How much weaker, I don't know 40% 50% 75%.

That's my point it's not gear failure. The thing self cleans.

Nobody expects a full KN rating.

I want that piece to fail with metal destroying glory.

I looked at my C4's and this will not happen to them because the trigger floats along the stem.

|

|

|

michael s

·

Mar 5, 2014

·

Denver, CO

· Joined Apr 2012

· Points: 80

Brassmonkey wrote: Think about it another way, if this wasn't a BD product, but rather something like a Climb-X cam someone bought off of the clymb then what would you be saying. And be honest with yourself. This is a really good point! And if the cam was made by McDonalds and came in a Happy Meal what would I be saying then?

|

|

|

Nate Solnit

·

Mar 5, 2014

·

Bath, NH

· Joined May 2013

· Points: 0

All cams/ gear will have perks and failings. This issue, while valid, just tells me to watch the trigger bar while placing super flexible stemmed cams, especially x4s, but not that I should sell them. I picked up the x4's because I personally don't like the c3's. I find it difficult to judge their placements because of the asymmetrical lobes. Yes, this is a personal failing that could be fixed, but my point is that all gear is going to have different issues that lend to its misuse. If placed correctly there should be minimal movement/rotation of the cam and the trigger bar will spin to lay flush with the wall.

|

|

|

Kerr Adams

·

Mar 5, 2014

·

Albuquerque, NM

· Joined Nov 2010

· Points: 155

The cams were not placed perpendicular. I put them in and looked at them before i took.

|

|

|

Rob D

·

Mar 5, 2014

·

Queens, NY

· Joined May 2011

· Points: 30

Kerr Adams wrote:The cams were not placed perpendicular. I put them in and looked at them before i took. This thread isn't about whether your gear was bad, it's about gear placed perpendicular and your accident was just the catalyst.

|

|

|

Kerr Adams

·

Mar 5, 2014

·

Albuquerque, NM

· Joined Nov 2010

· Points: 155

"So it's obvious from these pictures that the cam was placed perpendicular to the fall line."

|

|

|

Ryan Watts

·

Mar 5, 2014

·

Bishop, CA

· Joined Apr 2013

· Points: 25

Nate Solnit wrote:All cams/ gear will have perks and failings. This issue, while valid, just tells me to watch the trigger bar while placing super flexible stemmed cams, especially x4s, but not that I should sell them. I picked up the x4's because I personally don't like the c3's. I find it difficult to judge their placements because of the asymmetrical lobes. Yes, this is a personal failing that could be fixed, but my point is that all gear is going to have different issues that lend to its misuse. If placed correctly there should be minimal movement/rotation of the cam and the trigger bar will spin to lay flush with the wall. This. Mastercams allegedly have the same "problem" yet people have been whipping on them for years with no reports of this happening in the field. Doesn't mean it couldn't happen but it's probably not high on the list of risks we take while climbing. If you are placing cams perpendicular to the fall line in a vertical crack and then whipping on it I'd say maybe you want to work on those placements before running out and buying a new set of cams. I don't own any x4s but I've climbed with them before and wouldn't hesitate to in the future.

|

|

|

rocknice2

·

Mar 5, 2014

·

Montreal, QC

· Joined Nov 2006

· Points: 3,847

Kerr Adams wrote:"So it's obvious from these pictures that the cam was placed perpendicular to the fall line." Kerr I'm sorry that was a poor choice of words. This thread was not meant to be about you but I did use your photos. What I should have said was that the cam was loaded perpendicular to the fall line. Sorry and I hope you recover quickly

|

Continue with onX Maps

Continue with onX Maps Continue with Facebook

Continue with Facebook